Abstract

Studies involving the use of residual biomass from processes have grown substantially. In this context, the efficiency of the production of second-generation ethanol and carboxymethylcellulose from sugarcane bagasse was evaluated in this work. Therefore, sugarcane bagasse was characterized and submitted to pretreatment with different low-cost ionic liquids [sec-butylammonium acetate (IL1); sec-butylammonium lactate (IL2); imidazolium acetate (IL3), and imidazolium lactate (IL4)]. After verifying the greater efficiency of the treatment performed with IL1, a new treatment was carried out with this ionic liquid. The pretreated material was subjected to enzymatic hydrolysis steps, modifying the hydrolysis time and the concentrations of treated sugar cane bagasse (%). The best pretreatment condition (63.8 h, 12.2% of pretreated bagasse, 50 °C, pH 4.8, enzyme concentration of 20 FPU.gram−1 e, 250 rpm) enabled the conversion of pretreated sugarcane bagasse of 54.57 ± 0.28%. The sugarcane bagasse was submitted to the hydrolysis process using this condition, and the hydrolysate was used to the fermentation stage with a yield of 71.77% after 24 h. The residual holocellulose produced after hydrolysis produced a carboxymethylcellulose (CMC), making it possible to obtain it with a degree of substitution equal to 1.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Andrade Neto JC, Cabral AS, Oliveira LRD, Torres RB, Morandim-Giannetti AA (2016) Synthesis and characterization of new low-cost ILs based on butylammonium cation and application to lignocellulose hydrolysis. Carbohydr Polym 143:279–287

Andrade Neto JC, Pereira GJ, Morandim-Giannetti AA (2020) Lignocellulosic derivative and chitosan bioadsorbent: synthesis, characterization, and performance in chromium adsorption. J Appl Polym Sci 137:49208

Ariaeenejad S, Motamedi E, Salekdeh GH (2020) Stable cellulase immobilized on graphene oxide@CMC-g-poly(AMPS-co-AAm) hydrogel for enhanced enzymatic hydrolysis of lignocellulosic biomass. Carbohydr Polym 230:115661

Ayodele BV, Alsaffar MA, Mustapa SI (2020) An overview of integration opportunities for sustainable bioethanol production from first- and second-generation sugar-based feedstocks. J Clean Prod 245:118857

Brar KK, Raheja Y, Chadha BS, Magdouli S, Brar SK, Yang YH, Bhatia SK, Koubaa A (2022) A paradigm shift towards production of sustainable bioenergy and advanced products from Cannabis/hemp biomass in Canada. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-02570-6. (Biomass Conver Biorefin 1–22)

Cañadas R, Martín-Sampedro R, González-Miquel M, González EJ, Ballesteros I, Eugenio ME, Ibarra D (2023) Green solvents extraction-based detoxification to enhance the enzymatic hydrolysis of steam-exploded lignocellulosic biomass and recover bioactive compounds. J Environ Manag 344:118448

Chang KL, Chen XM, Wang XQ, Han YJ, Potprommanee L, Liu JY, Liao YL, Ning X, Sun S, Huang Q (2017) Impact of surfactant type for ionic liquid pretreatment on enhancing delignification of rice straw. Bioresour Technol 227:388–392

Cooper J, Kavanagh J, Razmjou A, Chen V, Leslie G (2020) Treatment and resource recovery options for first and second generation bioethanol spentwash: a review. Chemosphere 241:124975

Donkor KO, Gottumukkala LD, Lin R, Murphy JD (2022) A perspective on the combination of alkali pre-treatment with bioaugmentation to improve biogas production from lignocellulose biomass. Bioresour Technol 351:126950

Gao X, Yu Y, Jiang Z, Liu Y, Zhang W, Zhang L (2018) Direct dissolution and spinning of the agricultural waste of corn straw pulp. BioResources 13:4916–4930

Kumar JA, Sathish S, Prabu D, Renita AA, Saravanan A, Deivayanai VC, Anish M, Jayaprabakar J, Baigenzhenov O, Hosseini-Bandegharaei A (2023) Agricultural waste biomass for sustainable bioenergy production: feedstock, characterization and pre-treatment methodologies. Chemosphere 331:138680

Li X, Jin X, Wu Y, Zhang D, Sun F, Ma H, Pugazhendhi A, Xia C (2023) A comprehensive review of lignocellulosic biomass derived materials for water/oil separation. Sci Total Environ 876:162549

Liu G, Zhao X, Chen C, Chi Z, Zhang Y, Cui Q, Chi Z, Liu YJ (2020) Robust production of pigment-free pullulan from lignocellulosic hydrolysate by a new fungus co-utilizing glucose and xylose. Carbohydr Polym 241:116400

Lugani Y, Rai R, Prabhu AA, Maan P, Hans M, Kumar V, Chandel AK, Sengar RS (2020) Recent advances in bioethanol production from lignocelluloses: a comprehensive review with a focus on enzyme engineering and designer biocatalysts. Biofuel Res J 7:1267–1295

Ma Q, Gao X, Bi X, Han Q, Tu L, Yang Y, Shen Y, Wang M (2020) Dissolution and deacetylation of chitin in ionic liquid tetrabutylammonium hydroxide and its cascade reaction in enzyme treatment for chitin recycling. Carbohydr Polym 230:115605

Miller GL (1959) Use of Dinitrosalicylic Acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Mo W, Ke K, Shen X, Li B (2020) The influence of thermal drying pretreatment on enzymatic hydrolysis of cellulose and xylan in poplar fibers with high lignin content. Carbohydr Polym 228:115400

Montipó S, Ballesteros I, Fontana RC, Liu S, Ballesteros M, Martins AF, Camassola M (2019) Bioprocessing of rice husk into monosaccharides and the fermentative production of bioethanol and lactate. Cellulose 26:7309–7322

Mora-Pale M, Meli L, Doherty TV, Linhardt RJ, Dordick JS (2011) Room temperature ionic liquidsas emerging for the pretreatment of lignocellulosic biomass. Biotechnol Bioeng 108:1229–1245

Morais JPS, Rosa MF, Marconcini JM (2010) Documento 236: Procedimento para análise lignocelulósicas. EMBRAPA, Campina Grande

New EK, Wu TY, Lee CBTL, Poon ZY, Loow Y-L, Foo LYW, Procentese A, Siow LF, Teoh WH, Daud NNN (2019) Potential use of pure and diluted choline chloride-based deep eutectic solvent in delignification of oil palm fronds. Process Saf Environ Protect 123:190–198

Ocreto JB, Chen WH, Rollon AP, Ong HC, Pétrissans A, Pétrissans M, De Luna MDG (2022) Ionic liquid dissolution utilized for biomass conversion into biofuels, value-added chemicals and advanced materials: a comprehensive review. Chem Eng J 445:136733

Odorico FH, Morandim-Giannetti AA, Lucarini AC, Torres RB (2018) Pretreatment of Guinea grass (Panicum maximum) with the ionic liquid 1-ethyl-3-methyl imidazolium acetate for efficient hydrolysis and bioethanol production. Cellulose 25:2997–3009

Padmanabhan SK, Lamanna L, Friuli M, Sannino A, Demitri C, Licciulli A (2023) Carboxymethylcellulose-based Hydrogel obtained from bacterial cellulose. Molecules 28:829

Patel AK, Singhania RR, Sim SJ, Pandey A (2019) Thermostable cellulases: current status and perspectives. Bioresour Technol 279:385–392

Pendse DS, Deshmukh M, Pande A (2023) Different pre-treatments and kinetic models for bioethanol production from lignocellulosic biomass: a review. Heliyon 9: e16604

Pin TC, Rabelo SC, Pu Y, Ragauskas AJ, Costa AC (2021) Effect of protic ionic liquids in sugar cane bagasse pretreatment for lignin valorization and ethanol production. ACS Sustain Chem Eng 9:16965–16976

Radhakrishnan R, Patra P, Das M, Ghosh A (2021) Recent advancements in the ionic liquid mediated lignin valorization for the production of renewable materials and value-added chemicals. Renew Sust Energy Rev 149:111368

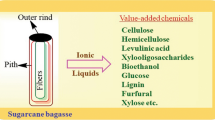

Rajamani S, Santhosh R, Raghunath R, Jadhav SA (2021) Value-added chemicals from sugarcane bagasse using ionic liquids. Chem Pap 75:5605–5622

Ribeiro WCO, Lima ACS, Morandim-Giannetti AA (2018) Optimizing treatment condition of coir fiber with ionic liquid and subsequent enzymatic hydrolysis for future bioethanol production. Cellulose 25:527–536

Roy S, Chundawat SP (2023) Ionic liquid–based pretreatment of lignocellulosic biomass for Bioconversion: a critical review. Bioenergy Res 16:263–278

Sharma V, Nargotra P, Sharma S, Bajaj BK (2020) Efficient bioconversion of sugarcane tops biomass into biofuel-ethanol using an optimized alkali-ionic liquid pretreatment approach. Biomass Convers Biorefin 13:841–854

Srivastava N, Srivastava M, Mishra PK, Gupta VK, Molina G, Rodriguez-Couto S, Manikanta A, Ramteke PW (2018) Applications of fungal cellulases in biofuel production: advances and limitations. Renew Sust Energy Rev 82:2379–2386

Stanley JT, Thanarasu A, Kumar PS, Periyasamy K, Raghunandhakumar S, Periyaraman P, Devaraj K, Dhanasekaran A, Subramanian S (2022) Potential pre-treatment of lignocellulosic biomass for the enhancement of biomethane production through anaerobic digestion—a review. Fuel 318:123593

Sukhang S, Choojit S, Reungpeerakul T, Sangwichien C (2020) Bioethanol production from oil palm empty fruit bunch with SSF and SHF processes using Kluyveromyces marxianus yeast. Cellulose 27:301–314

Sun C, Meng X, Sun F, Zhang J, Tu M, Chang JS, Reungsang A, Xia A, Ragauskas AJ (2022) Advances and perspectives on mass transfer and enzymatic hydrolysis in the enzyme-mediated lignocellulosic biorefinery: a review. Biotech Adv 62:108059

Trinh LTP, Lee YJ, Park CS, Bae HJ (2019) Aqueous acidified ionic liquid pretreatment for bioethanol production and concentration of produced ethanol by pervaporation. J Ind Eng Chem 69:57–65

TAPPI-Technical Association of the Pulp and Paper Industry. Useful Methods (1976). Provisional test methods, and useful test methods-fibrous materials and pulp testing, Atlanta, USA, Np

TAPPI – Technical Association of the Pulp and Paper Industry. Official Test Methods (1979) Provisional test methods, and useful test methods-fibrous materials and pulp testing, Atlanta, USA, Np

Usmani Z, Sharma M, Gupta P, Karpichev Y, Gathergood N, Bhat R, Gupta VK (2020) Ionic liquid based pretreatment of lignocellulosic biomass for enhanced bioconversion. Bioresour Technol 304:123003

Vieira S, Barros MV, Sydney ACN, Piekarski CM, Francisco AC, Vandenberghe SLP, Sydney EB (2020) Sustainability of sugarcane lignocellulosic biomass pretreatment for the production of bioethanol. Bioresour Technol 299:122635

Wagle A, Angove MJ, Mahara A, Wagle A, Mainali B, Martins M, Goldbeck R, Paudel SR (2022) Multi-stage pre-treatment of lignocellulosic biomass for multi-product biorefinery: a review. Sustain Energy Technol Assess 49:101702

Wang Z, Jiang Y, Mao L, Mao S, Deng M, Liang X (2023) Pilot-scale preparation of cellulose/carboxymethylcellulose composite fiber for methylene blue adsorption. Cellulose 30:3611–3623

Wise LEM, Murphy A, Addieco AD (1946) Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicellulose. Paper Trade J 122:35–43

Xiao MZ, Chen WJ, Cao XF, Chen YY, Zhao BC, Jiang ZH, Yuan TQ, Sun RC (2020) Unmasking the heterogeneity of carbohydrates in heartwood, sapwood, and bark of Eucalyptus. Carbohydr Polym 238:116212

Zanuso E, Ruiz HA, Domingues L, Teixeira JA (2022) Oscillatory flow bioreactor operating at high solids loading for enzymatic hydrolysis of lignocellulosic biomass. Biochem Eng J 187:108632

Zhang Q, Yang J, Zhang T, Shui X, Zhang H, Chen Z, He X, Lei T, Jiang D, Elgorban AM, Syed A, Solanki MK (2023) Pretreatment of Arundo donax L. for photo-fermentative biohydrogen production by ultrasonication and ionic liquid. Bioresour Technol 377:128904

Acknowledgments

We thank Dr. Nivaldo Boralle for the NMR measurements and LMA-IQ UNESP-Araraquara-SP, Brazil, for making the high-resolution electronic scanning microscope available.

Funding

Centro Universitário FEI supported this work.

Author information

Authors and Affiliations

Contributions

GRV performed the experiments, and AAMG assisted in interpreting the results. AAMG and GRV wrote the main manuscript text. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

No results of studies involving humans or animals are reported.

Consent for publication

AAMG and GRV approved the manuscript before submission and approval.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vedia, G.R., de Araújo Morandim-Giannetti, A. Production of second-generation ethanol and carboxymethylcellulose from sugarcane bagasse pretreated with low-cost ionic liquids. Cellulose 30, 10767–10781 (2023). https://doi.org/10.1007/s10570-023-05554-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05554-5