Abstract

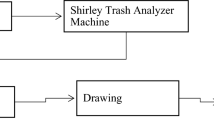

Agro-based weedy plants are ubiquitous globally and adversely impact the environment, agriculture, and human health. Thus, it would be a noteworthy accomplishment to mitigate the impact of these inescapable plants by repurposing them for beneficial ends. The present study employed the utilization of an agro-based weedy plant, namely “Urena lobata,” to manage agro-based waste effectively. For the first time, this study investigates the feasibility of manufacturing Urena lobata (UL) blend yarn in the ring spinning system. The Urena lobata (UL) fiber, which is naturally extracted, is a bast fiber with a long staple length. This fiber is processed into staple form and subsequently blended with cotton and polyester fibers. In this research, the maximum ratio of Urena lobata (UL) fiber in the form of chemically treated and untreated fiber was 25%, a homogenous blend with cotton and polyester to spun blend yarn using the conventional ring spinning system. Chemically treated and untreated 75/25% cotton/Urena lobata (CO/UL) and 75/25% Polyester/Urena lobata (PO/UL) blend yarns were characterized by their unevenness (U%), irregularity index (I), imperfection index (IPI), hairiness, and bundle yarn strength. Furthermore, optical microscopic images were utilized to observe the morphological characteristics of the fiber structure in the longitudinal view of the yarn. The Chemically treated Urena lobata (UL) blend yarn exhibited superior outcomes in comparison to untreated Urena lobata (UL) blend yarn. The chemical treatment of the blended yarn resulted in performance levels that fell within acceptable ranges. This indicates that the blended yarn can be deemed a sustainable blend component that is capable of meeting the current demand in the textile spinning industry.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Babu SS, Madhuri DB, Ali SL (2016) A pharmacological review of Urena lobata plant. Asian J Pharm Clin Res 9(2):20–22

Barsha UH, Uddin M, Hasan M, Chowdhury S (2018) Investigation on physical properties of jute cotton (jutton) blended fabric. Int J Text Fash Technol 8(2):1–8

Basu G, Roy AN (2008) Blending of jute with different natural fibres. J Nat Fibers 4(4):13–29

Bharathi SV, Vinodhkumar S, Saravanan M (2021). Strength characteristics of banana and sisal fiber reinforced composites. IOP Conference Series: Materials Science and Engineering, IOP Publishing

Chatterjee K, Geo-Pal N (1967) Blending of Jute and Sunnhemp on Jute Machinery. Text Manuf 93:513

Chatterji K, Bandyopadhyay S (1964) Blending of jute and mesta on jute machinery. Text Res J 34(11):967–973

Chattopadhyay SK, Dey SK, Venugopal B, Chaphekar A (2008) Value added knits from ramie-cotton blended yarns spun using short staple (cotton) spinning system. 2008 International Conference on Flax & other Bast Plants, Saskatoon, Citeseer

Cui Y, Song H, Cheng L, Deng W, Ji Y (2021) Experimental study of a modified drafting system based on the ring spinning frame. Text Res J 91(13–14):1486–1496

Islam MR, Ahmed S, Siddik MA, Ashique SM (2021) Analysis of cotton yarn properties spun on aerodynamic compact and open-end rotor spinning. J Text Sci Technol 7(1):22–40

Islam MT, Uddin MA (2017) A revision on Urena lobata L. International Journal of Medicine 5(1):126–131

ISO (1833) 1: 2010. Textiles–Quantitative chemical analysis–Part 1

Jalil MA, Moniruzzaman M, Parvez MS, Siddika A, Gafur MA, Repon MR, Hossain MT (2021) A novel approach for pineapple leaf fiber processing as an ultimate fiber using existing machines. Heliyon 7(8):e07861

Jena PK, Mohanty JR, Nayak S, Panda KR, Sahu R, Khuntia SK (2022) Utilization of chemically modified novel Urena lobata fibers as reinforcement in polymer composites–an experimental study. J Nat Fibers 19(7):2479–2489

Komuraiah A, Kumar NS, Prasad BD (2014) Chemical composition of natural fibers and its influence on their mechanical properties. Mech Compos Mater 50:359–376

Lee KE (2017) Environmental sustainability in the textile industry. Sustain Text Ind. https://doi.org/10.1007/978-981-10-2639-3_3

Mazumder M, Sen S, Dasgupta P (1976) Processing of degummed ramie on jute machinery. Indian Text J 86(4):87

Mazumder M, Sen S, Gupta PD (1975) Blending of ramie with jute for fine yarn production. Indian Text J 85(11):135

Mert E, Böhnisch S, Psikuta A, Bueno M-A, Rossi RM (2016) Contribution of garment fit and style to thermal comfort at the lower body. Int J Biometeorol 60:1995–2004

Mwaikambo LA, Ansell MP (2006) Mechanical properties of alkali treated plant fibres and their potential as reinforcement materials. I. hemp fibres. J Mater Sci 41:2483–2496

Njoku CE, Omotoyinbo JA, Alaneme KK, Daramola MO (2020) Structural characterization and mechanical behaviour of sodium hydroxide-treated Urena lobata fiber reinforced polypropylene matrix composites. Fibers Polym 21:2983–2992

Njoku CE, Omotoyinbo JA, Alaneme KK, Daramola MO (2022) Characterization of Urena lobata fibers after alkaline treatment for use in polymer composites. J Nat Fibers 19(2):485–496

Perum S, Iliev B, Zoneva H, Ilieva B (1985) “Method for the production of fine (hemp) jute yarns.” Priority application: Bulgaria. Pat Class 129:724

Salam M, Farouqui F, Mondal MI (2007) A study on sulphonated jute-cotton blended yarn and fabrics and their characteristics. Bangladesh J Sci Ind Res 42(3):281–286

Shahid MA, Ahmed F, Mahabubuzzaman A (2012) Study on the physical properties of jute-cotton blended rotor yarn. SUST J Sci Technol 20(6):84–88

Skenderi Z, Kopitar D, Ražić SE, Iveković G (2019) Study on physical-mechanical parameters of ring-, rotor-and air-jet-spun modal and micro modal yarns. Tekstilec 62(1):42–53

Skenderi Z, Kopitar D, Vrljičak Z, Iveković G (2018) "Unevenness of air-jet spun yarn comparison with ring and rotor spun yarn made from micro modal fibers. Tekstil Časopis Za Tekstilnu i Odjevnu Tehnologiju 67(1–2):14–26

Soe AK, Takahashi M, Nakajima M, Matsuo T, Matsumoto T (2004) Structure and properties of MVS yarns in comparison with ring yarns and open-end rotor spun yarns. Text Res J 74(9):819–826

Tao W, Calamari TA, Yu C, Chen Y (1999) Preparing and characterizing kenaf/cotton blended fabrics. Text Res J 69(10):720–724

Testing, A. S. f. and Materials (2017).ASTM D1059-17. Standard test method for yarn number based on short-length specimens

Velumani A, Kandhavadivu P, Parthiban M (2021) Influence of blend proportion on mechanical properties of banana/cotton blended knit fabric

Wang W-M, Cai Z-S, Yu J-Y (2008) Study on the chemical modification process of jute fiber. J Eng Fibers Fabr 3(2):155892500800300200

Acknowledgments

The authors would like to express thanks and gratitude to Multazim Spinning Mill Ltd, Mymenshing, Dhaka, Bangladesh, for providing machinery and testing equipment on time during this experiment and TÜV SÜD Bangladesh Pvt. Ltd, Dhaka, Bangladesh for other assistance that made this work possible. The authors declare that they have no conflict of interest.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

KH: Conceived and designed the experiments; Performed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper and reviewed the manuscript. SR: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Prepared the graphs; Wrote the paper and reviewed the manuscript. ABH: Analyzed and interpreted the data; Prepared the graphs and reviewed the manuscript. MT: Performed the experiments and reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hasan, K., Rahman, S., Habib, M.B. et al. A sustainable approach to utilize an agro-based weedy plant “Urena lobata” in blend yarn manufacturing in short-staple ring spinning. Cellulose 30, 9815–9827 (2023). https://doi.org/10.1007/s10570-023-05465-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05465-5