Abstract

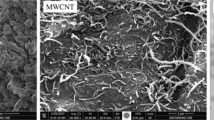

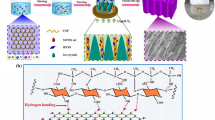

Over the past decade, cellulose microtube-based foam materials have gained immense traction for their potential applications in construction, transportation, electronics, and so on with the gradual deterioration of the environment and the rapid depletion of fossil resources. However, the cellulose microtube-based foam materials have some disadvantages-the poor thermal insulation properties derived from the large and uneven pore structure, the low mechanical strength derived from the fewer microtube bonding points, and so on. These disadvantages limit their wide usage. In this paper, we are committed to enhance the performance of the cellulose microtube-based (CMT) foam materials, using aramid nanofiber (ANF) aerogel to fill the large and uneven pore structure of the CMT foam materials. The ANF suspension can be quickly and evenly adsorbed by the large and uneven porous structure of the CMT foam materials. The ANF aerogels can fill in the pores of the CMT foam materials uniformly. The morphology, microstructure, BET surface area, pore structure, and mechanical strength of the cellulose microtube/aramid nanofiber (CMT/ANF) composite foam can be effectively tuned by the concentration of the ANF suspension. The CMT/ANF-0.6 composite foam has the best thermal insulation properties. The temperature difference of the CMT/ANF-0.6 composite foam was 47, 72 and 109 °C when the temperature of the hot stage was 107, 155 and 208 °C.

Similar content being viewed by others

Data availability

The authors declare that the data and materials were available.

References

Bhat VS, Supriya S, Hegde G (2019) Review-biomass derived carbon materials for electrochemical sensors. J Electrochem Soc 167:037526. https://doi.org/10.1149/2.0262003JES

Cao M, Liu B-W, Zhang L, Peng Z-C, Zhang Y-Y, Wang H, Zhao H-B et al (2021) Fully biomass-based aerogels with ultrahigh mechanical modulus, enhanced flame retardancy, and great thermal insulation applications. Compos Part B Eng 225:109309. https://doi.org/10.1016/j.compositesb.2021.109309

Chen C, Zhou Y, Xie W, Meng T, Zhao X, Pang Z, Chen Q et al (2023) Lightweight, thermally insulating, fire-proof graphite‐cellulose foam. Adv Funct Mater 33:2204219. https://doi.org/10.1002/adfm.202204219

Dahunsi S (2019) Mechanical pretreatment of lignocelluloses for enhanced biogas production: methane yield prediction from biomass structural components. Bioresourc Technol 280:18–26. https://doi.org/10.1016/j.biortech.2019.02.006

Do NH, Tran VT, Tran QB, Le KA, Thai QB, Nguyen PT, Duong HM et al (2021) Recycling of pineapple leaf and cotton waste fibers into heat-insulating and flexible cellulose aerogel composites. J Polym Environ 29:1112–1121. https://doi.org/10.1007/s10924-020-01955-w

Dogu D, Tuncer FD, Bakir D, Candan Z (2017) Characterizing microscopic changes of paulownia wood under thermal compression. BioResources 12:5279–5295. https://doi.org/10.15376/biores.12.3.5279-5295

Elwakeel KZ, Ahmed MM, Akhdhar A, Sulaiman MGM, Khan ZA (2022) Recent advances in alginate-based adsorbents for heavy metal retention from water: a review. Desalin Water Treat 272:50–74. https://doi.org/10.5004/dwt.2022.28834

Gellerstedt G, Tomani P, Axegård P, Backlund B (2013) Lignin recovery and lignin-based products. RSC, Cambridge

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85. https://doi.org/10.1039/C0NR00583E

Jia X, Li J, Li F (2014) Biomass biodegradable starch material cushioning packaging products and plasticizing properties of compatibility. In: Paper presented at the 5th international conference on mechanical, industrial, and technologies M (MIMT), Penang, Malaysia

Ju R, Xu G, Xu L, Qi M, Wang D, Cao P-C, Xi R et al (2023) Convective thermal metamaterials: exploring high-efficiency, directional, and wave-like heat transfer. Adv Mater. https://doi.org/10.1002/adma.202209123

Kruse A, Funke A, Titirici M-M (2013) Hydrothermal conversion of biomass to fuels and energetic materials. Curr Opin Chem Biol 17:515–521. https://doi.org/10.1016/j.cbpa.2013.05.004

Li R, Du J, Zheng Y, Wen Y, Zhang X, Yang W, Lue A et al (2017) Ultra-lightweight cellulose foam material: preparation and properties. Cellulose 24:1417–1426

Li J, Yang X, Xiu H, Dong H, Song T, Ma F, Feng P et al (2019) Structure and performance control of plant fiber based foam material by fibrillation via refining treatment. Ind Crop Prod 128:186–193. https://doi.org/10.1016/j.indcrop.2018.10.085

Li J, Lu Z, Xie F, Huang J, Ning D, Zhang M (2021) Highly compressible, heat-insulating and self-extinguishing cellulose nanofiber/aramid nanofiber nanocomposite foams. Carbohyd Polym 261:117837. https://doi.org/10.1016/j.carbpol.2021.117837

Li M, Chen X, Li X, Dong J, Zhao X, Zhang Q (2022) Controllable strong and ultralight aramid nanofiber-based aerogel fibers for thermal insulation applications. Adv Fiber Mater 4:1267–1277. https://doi.org/10.1007/s42765-022-00175-2

Lyu J, Liu Z, Wu X, Li G, Fang D, Zhang X (2019) Nanofibrous kevlar aerogel films and their phase-change composites for highly efficient infrared stealth. ACS Nano 13:2236–2245. https://doi.org/10.1021/acsnano.8b08913

Makarem M, Lee CM, Kafle K, Huang S, Chae I, Yang H, Kubicki JD et al (2019) Probing cellulose structures with vibrational spectroscopy. Cellulose 26:35–79. https://doi.org/10.1007/s10570-018-2199-z

Mohan K, Ganesan AR, Ezhilarasi PN, Kondamareddy KK, Rajan DK, Sathishkumar P, Rajarajeswaran J et al (2022) Green and eco-friendly approaches for the extraction of chitin and chitosan: a review. Carbohyd Polym 287:119349. https://doi.org/10.1016/j.carbpol.2022.119349

Mokhena TC, John MJ (2020) Cellulose nanomaterials: new generation materials for solving global issues. Cellulose 27:1149–1194. https://doi.org/10.1007/s10570-019-02889-w

Ng KF, Nair NK, Liew KY, Noor AM (1997) Surface and pore structure of deoiled acid- and heat-treated spent bleaching clays. J Am Oil Chem Soc 74:963–970. https://doi.org/10.1007/s11746-997-0012-5

Niu Q, Tang Q, Sun X, Wang L, Gao K (2022) Wood-based carbon tubes with low-tortuosity and open tubular structure for energy storage application. J Mater Sci 57:5154–5166. https://doi.org/10.1007/s10853-022-06973-8

Nzihou A, Stanmore B, Lyczko N, Minh DP (2019) The catalytic effect of inherent and adsorbed metals on the fast/flash pyrolysis of biomass: a review. Energy 170:326–337. https://doi.org/10.1016/j.energy.2018.12.174

Patel A, Wilcox K, Li Z, George I, Juneja R, Lollar C, Lazar S et al (2020) High modulus, thermally stable, and self-extinguishing aramid nanofiber separators. ACS Appl Mater Inter 12:25756–25766. https://doi.org/10.1021/acsami.0c03671

Pennells J, Godwin ID, Amiralian N, Martin DJ (2020) Trends in the production of cellulose nanofibers from non-wood sources. Cellulose 27:575–593. https://doi.org/10.1007/s10570-019-02828-9

Popp J, Kovacs S, Olah J, Diveki Z, Balazs E (2021) Bioeconomy: biomass and biomass-based energy supply and demand. New Biotechnol 60:76–84. https://doi.org/10.1016/j.nbt.2020.10.004

Seddiqi H, Oliaei E, Honarkar H, Jin J, Geonzon LC, Bacabac RG, Klein-Nulend J (2021) Cellulose and its derivatives: towards biomedical applications. Cellulose 28:1893–1931. https://doi.org/10.1007/s10570-020-03674-w

Sehaqui H, Zhou Q, Berglund LA (2011) High-porosity aerogels of high specific surface area prepared from nanofibrillated cellulose (NFC). Compos Sci Technol 71:1593–1599. https://doi.org/10.1016/j.compscitech.2011.07.003

Sharma G, Kaur M, Punj S, Singh K (2020) Biomass as a sustainable resource for value-added modern materials: a review. Biofuel Bioprod Bior 14:673–695. https://doi.org/10.1002/bbb.2079

Sun Y, Chu Y, Wu W, Xiao H (2021a) Nanocellulose-based lightweight porous materials: a review. Carbohyd Polym 255:117489. https://doi.org/10.1016/j.carbpol.2020.117489

Sun J, Wu Z, An B, Ma C, Xu L, Zhang Z, Luo S et al (2021b) Thermal-insulating, flame-retardant and mechanically resistant aerogel based on bio-inspired tubular cellulose. Compos Part B-eng 220:108997. https://doi.org/10.1016/j.compositesb.2021.108997

Tu H, Li X, Liu Y, Luo L, Duan B, Zhang R (2022) Recent progress in regenerated cellulose-based fibers from alkali/urea system via spinning process. Carbohyd Polym. https://doi.org/10.1016/j.carbpol.2022.119942

Wang D, Feng X, Zhang L, Li M, Liu M, Tian A, Fu S (2019a) Cyclotriphosphazene-bridged periodic mesoporous organosilica-integrated cellulose nanofiber anisotropic foam with highly flame-retardant and thermally insulating properties. Chem Eng J 375:121933. https://doi.org/10.1016/j.cej.2019.121933

Wang Y, Qu Q, Gao S, Tang G, Liu K, He S, Huang C (2019b) Biomass derived carbon as binder-free electrode materials for supercapacitors. Carbon 155:706–726. https://doi.org/10.1016/j.carbon.2019.09.018

Xie C, Liu S, Zhang Q, Ma H, Yang S, Guo Z-X, Qiu T et al (2021) Macroscopic-scale preparation of aramid nanofiber aerogel by modified freezing–drying method. ACS Nano 15:10000–10009. https://doi.org/10.1021/acsnano.1c01551

Yang M, Cao K, Sui L, Qi Y, Zhu J, Waas A, Arruda EM et al (2011) Dispersions of aramid nanofibers: a new nanoscale building block. ACS Nano 5:6945–6954. https://doi.org/10.1021/nn2014003

Yang B, Wang L, Zhang M, Luo J, Ding X (2019a) Timesaving, high-efficiency approaches to fabricate aramid nanofibers. ACS Nano 13:7886–7897. https://doi.org/10.1021/acsnano.9b02258

Yang B, Zhang M, Lu Z, Tan J, Luo J, Song S, Ding X et al (2019b) Comparative study of aramid nanofiber (ANF) and cellulose nanofiber (CNF). Carbohyd Polym 208:372–381. https://doi.org/10.1016/j.carbpol.2018.12.086

Yang B, Wang L, Zhang M, Luo J, Lu Z, Ding X (2020) Fabrication, applications, and prospects of aramid nanofiber. Adv Funct Mater 30:2000186. https://doi.org/10.1002/adfm.202000186

Yang B, Li W, Zhang M, Wang L, Ding X (2021) Recycling of high-value-added aramid nanofibers from waste aramid resources via a feasible and cost-effective approach. ACS Nano 15:7195–7207. https://doi.org/10.1021/acsnano.1c00463

Zhang J, Chen W, Feng Y, Wu J, Yu J, He J, Zhang J (2015) Homogeneous esterification of cellulose in room temperature ionic liquids. Polym Int 64:963–970. https://doi.org/10.1002/pi.4883

Zhang Q, Cheng Y, Fang C, Shi J (2022) Construction of novel regenerated cellulose based foam derived from waste cigarette filters as effective oil adsorbent. J Appl Polym Sci 139:51900. https://doi.org/10.1002/app.51900

Zhang W, Zhang P, Wang H, Li J, Dai SY (2022) Design of biomass-based renewable materials for environmental remediation. Trends Biotechnol 40:1519–1534. https://doi.org/10.1016/j.tibtech.2022.09.011

Zhou B, Han G, Zhang Z, Li Z, Feng Y, Ma J, Liu C et al (2021) Aramid nanofiber-derived carbon aerogel film with skin-core structure for high electromagnetic interference shielding and solar-thermal conversion. Carbon 184:562–570. https://doi.org/10.1016/j.carbon.2021.08.067

Zhu Z, Xu Z (2020) The rational design of biomass-derived carbon materials towards next-generation energy storage: a review. Renew Sustain Energ Rev 134:110308. https://doi.org/10.1016/j.rser.2020.110308

Funding

This work was supported by the Science and Technology Research Project of Henan Province (222102230031), Key Scientifc Research Projects of Colleges and Universities in Henan Province (23A430018).

Author information

Authors and Affiliations

Contributions

QN and KG: Idea for the article, literature search and analysis, experiment, writing and revision of the manuscript. DS: literature search and experiment. QT: Idea for the article, analysis, revision of the manuscript. XS: analysis, revision of the manuscript. LW: experimental protocol design. YZ: Revision of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Consent for publication

The authors approved the version to be published.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Niu, Q., Sun, D., Gao, K. et al. Cellulose microtube/aramid nanofiber composite foam. Cellulose 30, 9453–9463 (2023). https://doi.org/10.1007/s10570-023-05450-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05450-y