Abstract

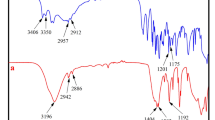

High-effective and eco-friendly flame retardants have been drawing more and more attention. Herein, an eco-friendly B/P/N flame retardant (BPNM) was synthesized by esterification of phosphorylated meglumine and boric acid, and then ammoniated by urea. The flame-retardant cotton fabric of high-efficiency and durability was fabricated by durable dipping-padding treatment. The results showed that the optimal preparation condition of BPNM were at the molar ratio of meglumine to boric acid 1:4 at 130 °C for 2 h. B/P/N elements of BPNM accounted for 35.73%. The limit oxygen index (LOI) of BPNM cotton fabric reached the maximum 40.1% and was 2.2 times higher than that of the pristine fabric. BPNM cotton fabric exhibited no after-flame time and after-glow time. Compared with the untreated fabric, peak heat release rate, total heat release rate, and CO2/CO of BPNM cotton fabric decreased by 6.6 times, 48%, and 10 times, respectively. BPNM cotton fabric gathered the gas phase and the condense phase flame-retardant mechanism. After 30 laundry cycles, LOI of BPNM cotton fabric still maintained at 30.5%.

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in this published article.

References

Ambekar RS, Deshmukh A, Suarez-Villagran MY, Das R, Pal V, Dey S, Miller JH, Machado LD, Kumbhakar P, Tiwary CS (2020) 2D hexagonal boron nitride-coated cotton fabric with self-extinguishing property. ACS Appl Mater Inter 12:45274–45280. https://doi.org/10.1021/acsami.0c12647

Bai YY, Li JX, Tai XM, Wang GY (2020) Preparation, characterization, and properties of novel meglumine-based polysiloxane surfactants. J Ind End Chem 84:236–242. https://doi.org/10.1016/j.jiec.2020.01.003

Basak S, Ali SW (2016) Sustainable fire retardancy of textiles using bio-macromolecules. Polym Degrad Stabil 133:47–64. https://doi.org/10.1016/j.polymdegradstab.2016.07.019

Bentis A, Boukhriss A, Gmouh S (2020) Flame-retardant and water-repellent coating on cotton fabric by titania–boron sol–gel method. J Sol-Gel Sci Techn 94:719–730. https://doi.org/10.1007/s10971-020-05224-z

Bhakare MA, Lokhande KD, Bondarde MP, Dhumal PS, Some S (2023) Dual functions of bioinspired, water-based, reusable composite as a highly efficient flame retardant and strong adhesive. Chem Eng J 254:140421. https://doi.org/10.1016/j.cej.2022.140421

Chan SY, Si LP, Lee KI, Ng PF, Chen L, Yu B, Hu Y, Yuen RKK, Xin JH, Fei B (2018) A novel boron–nitrogen intumescent flame retardant coating on cotton with improved washing durability. Cellulose 25:843–857. https://doi.org/10.1007/s10570-017-1577-2

Cobos M, Pagalday E, Puyadena M, Cabido X, Martin L, Múgica A, Irusta L, González A (2023) Waterborne hybrid polyurethane coatings containing casein as sustainable green flame retardant through different synthesis approaches. Prog Org Coat 174:107278. https://doi.org/10.1016/j.porgcoat.2022.107278

Cromwell B, Levenson A, Levine M (2020) Thermogravimetric analysis of aromatic boronic acids for potential flame retardant applications. Thermochim Acta 683:178476. https://doi.org/10.1016/j.tca.2019.178476

Dong Y, Chen W, Zhou X (2021) Synthesis and characterization of amino-terminated phosphorous polyborosiloxane and its effect on flame retardancy of polymethacrylimide. Mater Today Chem 20:100437. https://doi.org/10.1016/j.mtchem.2021.100437

Fan S, Sun YL, Wang XL, Yu JY, Wu DQ, Li FX (2020) A novel organic-inorganic flame retardant of ammonium polyphosphate chemically coated by Schiff base‐containing branched polysiloxane for polyamide 6. Polym Adv Technol 31:2763–2774. https://doi.org/10.1002/pat.5003

Gaan S, Mauclaire L, Rupper P, Salimova V, Tran TT, Heuberger M (2011) Thermal degradation of cellulose acetate in presence of bis-phosphoramidates. J Anal Appl Pyrol 90:33–41. https://doi.org/10.1016/j.jaap.2010.10.005

Gorham J, Torres J, Wolfe G, d’Agostino A, Fairbrother DH (2005) Surface reactions of molecular and atomic oxygen with carbon phosphide films. J Phys Chem B 109:20379–20386. https://doi.org/10.1021/jp0521196

Gou TT, Wu X, Zhao QY, Chang S, Wang P (2021) Novel phosphorus/nitrogen-rich oligomer with numerous reactive groups for durable flame-retardant cotton fabric. Cellulose 28:7405–7419. https://doi.org/10.1007/s10570-021-03980-x

Huo SQ, Sai T, Ran SY, Guo ZH, Fang ZP, Song PG, Wang H (2022) A hyperbranched P/N/B-containing oligomer as multifunctional flame retardant for epoxy resins. Compos Part B: Eng 234:109701. https://doi.org/10.1016/j.compositesb.2022.109701

Khalili P, Liu XL, Tshai KY, Rudd C, Yi XS, Kong I (2019) Development of fire retardancy of natural fiber composite encouraged by a synergy between zinc borate and ammonium polyphosphate. Compos Part B: Eng 159:165172. https://doi.org/10.1016/j.compositesb.2018.09.036

Kundu CK, Wang X, Song L, Hu Y (2018) Borate cross-linked layer-by-layer assembly of green polyelectrolytes on polyamide 66 fabrics for flame-retardant treatment. Prog Org Coat 121:173–181. https://doi.org/10.1016/j.porgcoat.2018.04.031

Lazar ST, Kolibaba TJ, Grunlan JC (2020) Flame-retardant surface treatments. Nat Reviews Mater 5:259–275. https://doi.org/10.1038/s41578-019-0164-6

Li JC, Fan BJ, Ren TH, Zhao YD (2015) Tribological study and mechanism of B-N and B-S-N triazine borate esters as lubricant additives in mineral oil. Tribol Int 88:1–7. https://doi.org/10.1016/j.triboint.2015.03.002

Li Z, Expósito DF, González AJ, Wang DY (2017) Natural halloysite nanotube based functionalized nanohybrid assembled via phosphorus-containing slow release method: a highly efficient way to impart flame retardancy to polylactide. Eur Polym J 93:458–470. https://doi.org/10.1016/j.eurpolymj.2017.06.021

Li N, Ming J, Yuan RC, Fan S, Liu L, Li FX, Wang XL, Yu JY, Wu D (2019) Novel eco-friendly flame retardants based on nitrogen–silicone schiff base and application in cellulose. ACS Sustain Chem Eng 8:290–301. https://doi.org/10.1021/acssuschemeng.9b05338

Lin DM, Zeng XR, Li HQ, Lai XJ, Wu TY (2019) One-pot fabrication of superhydrophobic and flame-retardant coatings on cotton fabrics via sol-gel reaction. J Colloid Interfac Sci 533:198–206. https://doi.org/10.1016/j.jcis.2018.08.060

Liu J, Qi P, Meng D, Li L, Sun J, Li HF, Gu XY, Jiang SL, Zhang S (2022) Eco-friendly flame retardant and smoke suppression coating containing boron compounds and phytic acids for nylon/cotton blend fabrics. Ind Crops Prod 186:115239. https://doi.org/10.1016/j.indcrop.2022.115239

Lu SY, Hamerton I (2002) Recent developments in the chemistry of halogen-free flame retardant polymers. Prog Polym Sci 27:1661–1712. https://doi.org/10.1016/S0079-6700(02)00018-7

Makhlouf G, Abdelkhalik A, Ameen H (2022) Preparation of highly efficient chitosan-based flame retardant coatings with good antibacterial properties for cotton fabrics. Prog Org Coat 163:106627. https://doi.org/10.1016/j.porgcoat.2021.106627

Nabipour H, Wang X, Rahman MZ, Song L, Hu Y (2020) An environmentally friendly approach to fabricating flame retardant, antibacterial and antifungal cotton fabrics via self-assembly of guanazole-metal complex. J Clean Prod 273:122832. https://doi.org/10.1016/j.jclepro.2020.122832

Ozer MS, Gaan S (2022) Recent developments in phosphorus based flame retardant coatings for textiles: synthesis, applications and performance. Prog Org Coat 171:107027. https://doi.org/10.1016/j.porgcoat.2022.107027

Qi P, Wang SH, Wang WJ, Sun J, Yuan HF, Zhang S (2022) Chitosan/sodium polyborate based micro-nano coating with high flame retardancy and superhydrophobicity for cotton fabric. Int J Biol Macromol 205:261–273. https://doi.org/10.1016/j.ijbiomac.2022.02.062

Rahimi-Aghdam T, Shariatinia Z, Hakkarainen Minna, Haddadi-Asl V (2019) Polyacrylonitrile/N,P co-doped graphene quantum dots-layered double hydroxide nanocomposite: Flame retardant property, thermal stability and fire hazard. Eur Polym J 120:109256. https://doi.org/10.1016/j.eurpolymj.2019.109256

Ren YL, Liu YS, Wang Y, Guo X, Liu XH (2020) Preparation of durable and flame retardant lyocell fabrics by using a biomass-based modifier derived from vitamin C. Cellulose 27:6677–6689. https://doi.org/10.1007/s10570-020-03218-2

Wang L, Sánchez-Soto M, Fan J, Xia ZP, Liu Y (2019) Boron/nitrogen flame retardant additives cross‐linked cellulose nanofibril/montmorillonite aerogels toward super‐low flammability and improved mechanical properties. Polym Adv Technol 30:1807–1817. https://doi.org/10.1002/pat.4613

Xu F, Zhong L, Zhang C, Wang P, Zhang FX, Zhang GX (2019) Novel high-efficiency casein-based P–N-containing flame retardants with multiple reactive groups for cotton fabrics. ACS Sustain Chem Eng 7:13999–14008. https://doi.org/10.1021/acssuschemeng.9b02474

Yan L, Xu ZS, Deng N (2019) Effects of polyethylene glycol borate on the flame retardancy and smoke suppression properties of transparent fire-retardant coatings applied on wood substrates. Prog Org Coat 135:123–134. https://doi.org/10.1016/j.porgcoat.2019.05.043

Zhang QH, Chen GQ, Xing TL (2017) Silk flame retardant finish by ternary silica sol containing boron and nitrogen. Appl Surf Sci 421:52–60. https://doi.org/10.1016/j.apsusc.2017.01.283

Zhu WJ, Yang MY, Huang H, Dai Z, Cheng BW, Hao SS (2020) A phytic acid-based chelating coordination embedding structure of phosphorus–boron–nitride synergistic flame retardant to enhance durability and flame retardancy of cotton. Cellulose 27:4817–4829. https://doi.org/10.1007/s10570-020-03063-3

Funding

This work was financially supported by National Natural Science Foundation of China (No. 51703202) and the Fundamental Research Funds of Zhejiang Sci-Tech University (No. 2021Q003).

Author information

Authors and Affiliations

Contributions

SY wrote the main manuscript. WLL modified the main manuscript. WMH checked all the figures and tables. WYJ prepared Figs. 1, 2, 3, 4, 5, 6 and 7. LH prepared Figs. 8, 9, 10, 11 and 12. All authors reviewed the manuscript. All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by YS, LW, MW, YW and HL. The first draft of the manuscript was written by YS and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval and consent to participate

The authors are compliance with ethical standards.

Consent for publication

Written informed consent for publication was obtained from all participants.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shi, Y., Wang, L., Wu, M. et al. An eco-friendly B/P/N flame retardant for its fabrication of high-effective and durable flame-retardant cotton fabric. Cellulose 30, 6621–6638 (2023). https://doi.org/10.1007/s10570-023-05265-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05265-x