Abstract

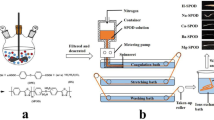

A new mechano-chemical formulation is developed for making flame resistant sisal fibre rope with low chemical loading. Sisal yarn is treated with a different formulation of ammonium sulfamate (AS) (50 g/L and 100 g/L) by following dip-dry approach at room temperature. Limiting oxygen index (LOI) measures the minimum amount of oxygen required in the mixture of nitrogen and oxygen for burning of the sample. Treated sisal showed LOI values of 28–32 and self-extinguishment in vertical flammability test whereas control sisal yarn showed LOI value of 21 and burnt easily within a minute. Forced combustion results revealed that AS treated sisal yarn exhibited 50% lower peak heat release rate (PHRR) than the control sisal yarn. Sisal yarn based rope was prepared by following braiding technique with three single yarns, using different combinations of untreated and treated sisal yarn. Fire retardant sheath yarn is used to cover the untreated sisal yarn present in the core by twisting or braiding. Rope made from sisal yarn has shown LOI value 30–40. Besides, a new method of simultaneous dyeing and flame retardant finishing of sisal rope is also proposed. The physical properties of the ropes were measured and it was found that the extent of strength loss is statistically insignificant at 95% confidence level. The thermal stability of the AS-treated sisal yarn is measured by thermo-gravimetric analysis. Charring behaviour of the control and AS treated sisal fibre was examined using microscopic images and scanning electron microscopy. Besides, in detail mechanism behind flame retardancy is revealed in the context with the help of XRD and FTIR analysis techniques.

Graphical Abstract

Similar content being viewed by others

Data availability

All the data, materials are original and generated from our research.

References

Basak S, Ali SW (2016) Sustainable fire retardancy of textiles using bio-macromolecules. Polym Degrad Stabil 133:47–64

Basak S, Ali SW (2019) Wastage pomegranate rind extracts (PRE): a one step green solution for bioactive and naturally dyed cotton substrate with special emphasis on its fire protection efficacy. Cellulose 26(5):3601–3623

Basak S, Samanta KK, Chattopadhyay SK, Das S, Narkar R, Shaikh AH (2014) Flame retardant and antimicrobial jute textile using sodium meta silicate nonahydrate. Pol J Chem Technol 16(2):106–113

Basak S, Samanta KK, Chattopadhyay SK, Narkar R (2015) Thermally stable cellulosic paper made using banana pseudostem sap, a wasted by product. Cellulose 22:2767–2776

Basak S, Patil PG, Shaikh AJ, Samanta AK (2016) Green coconut shell extract and boric acid: new formulation for making thermally stable cellulosic paper. J Chem Technol Biotechnol 91:2871–2881

Basak S, Kartick KK, Saxena S, Chattopadhyay SK, Parmar MS (2017) Self-extinguishable cellulosic fabric from Spinacia Oleracea. Ind J Fibre Text Res 42(2):215–222

Binder BJ, Gray MJ, White JF (2009) Reactions of lignin model compounds in ionic liquids. Biomass Bioenergy 33:1122–1130

Catling D, Grayson J (1982) Sisal In: Identification of Vegetable Fibers. Chapman and Hall, New York

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the Segal crystallinity index. Cellulose 20:583–588

Gazi ME, Sonnier R, Giraud S, Batistella M, Basak S, Dumazert L, Hajj R, Hage RE (2021) Fire behaviour of thermally thin materials in cone calorimeter. Polymers 13:1297–1305

Habibzade S, Taghiyari HR, Omidvar A, Roudi HR (2016) Effect of impregnation with styrene and nano ZnO on fire retarding, physical and mechanical properties of poplar wood. CERENE. https://doi.org/10.1590/01047760201622042213

Hady MM (2013) Flame retardancy and UV protection of cotton fabrics using nano ZnO and polycarboxylic acid. Carbohydr Polym 92:400–406

Horrocks AR (2004) Textiles in Fire retardant materials. Horrocks AR and Price D (Eds) Woodhead Publishing limited, CRC Press, DC, pp 128–178

Kambli N, Basak S, Samanta KK, Deshmukh RR (2018) Extraction of natural cellulosic fibre from corn husk and its physicochemical properties. Fibers Polym 17:687–694

Khan AM, Guru S, Padmakaran P, Mishra D, Mudgal M, Dhakad S (2011) Characterization studies and impact of chemical treatment on mechanical properties of sisal fibre. Compos Interfaces 18:527–541

Kandola BK, Horrocks AR, Price D, Coleman GV (1996) Flame retardant treatments of cellulose and their influence on the mechanism of cellulose pyrolysis. J Macromol Sci 36:794–799

Kazachenko AS, Akman F, Abdelmolalri H, Issaoui N, Malyar YN, Dossary OA, Wojcik MJ (2021) Intermolecular hydrogen bond interactions in water clusters of ammonium sulphamate: FTR, XRD, AIM, DFT, RDG, EIG, NBO analysis. J Mol Liq 342:117475–117484

Mostashari SM, Mostashari Z (2008) Combustion pathway of cotton fabrics treated by ammonium sulphate as flame retardant studied by TG. J Therm Anal Calorim 91:437–441

Mukherjee PS, Satyanarayana KG (1984) Structure and properties of some vegetable fibres. J Mater Sci 19(12):3925–3934

Music S, Vincekovic NF, Sekovanic L (2011) Precipitation of amorphous SiO2 particles and their properties. Braz J Chem Eng 28:89–94

Nandanwar R, Singh P, Haque FZ (2015) Synthesis and characterization of SiO2 nanoparticles by sol-gel process and its degradation of methylene blue. Am Chem Sci J 5:1–10

Samanta AK, Bhattacharya R, Bagchi A, Chowdhury R (2020) Statistical optimization of ammonium sulfamate and urea based fire protective finishing of jute fabric in functional textiles and clothing. Woodhead Publishing, Sawston, pp 304–315

Segal L, Creeley JJ, Martin AE, Conrad CM (1959) An emperical method for measuring degree of crystallinity of cellulose using X-ray Diffractometer. Text Res J 29:786–794

Seshama M, Khatri H, Suther M, Basak S, Ali SW (2017) Bulk Vs nano ZnO: influence of fire retardant behaviour on sisal fibre yarn. Carbohydr Polym 175:257–264

Shukla A, Basak S, Ali SW, Chattopadhyay R (2016) Development of fire-retardant sisal yarn. Cellulose 24:423–434

Sun Q, Lu Y, XiaDong jiangLiu YLJ (2015) Flame retardancy of wood treated by TiO2/ZnO coating. Surf Eng 28:555–559

Teli MD, Pandit P, Basak S (2017) Coconut shell extract imparting multifunctional properties to lingo-cellulosic material. J Indus Text 47:1261–1290

Acknowledgments

Thanks to ICAR-NINFET for providing continuous support to carry forward research work in this line

Funding

No.

Author information

Authors and Affiliations

Contributions

SB: Research planning, execution of research. MB: Research writing and analysis. SS: Research data analysis and picture correction.

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest involved in this research manuscript. In addition, no ethical issue will be hampered after publishing this context.

Ethical approval

There is no unethical data, table, picture and report has been presented in the manuscript. No table, figure and data has been copied from anywhere.

Consent for publication

We are giving consent for publication of this article. There is no conflict of interest involved in this research manuscript. In addition, no ethical issue will be hampered after publishing this context. Thanks to ICAR-NINFET for providing continuous support to carry forward research work in this line.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Basak, S., Bhowmick, M. & Sengupta, S. Flame retardant sisal rope: combustion properties and characterization. Cellulose 30, 3931–3952 (2023). https://doi.org/10.1007/s10570-023-05092-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05092-0