Abstract

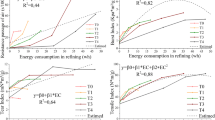

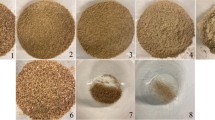

Countries with scarce soft and hardwood resources have been utilizing the non-wood based lignocellulosic biomass (mainly straw or bagasse), besides for bioenergy also for paper production. The increasing demand for wood-based bio solutions (energy and chemicals like lignin) have put cellulose for paper making under pressure. Paper producers are actively looking for alternatives for these purposes, especially for fibre-based packaging. In this study we have tested the flexo printability of six different papers partly made from invasive plants: Japanese Knotweed, Black Locust, Canadian Goldenrod, dedicated crop Miscanthus, and agro-residue Tomato stems and from industrial waste jute bags fibres. All the papers were produced on a pilot-scale paper machine. Fibre and paper properties were analyzed to determine the flexo printability, runnability and durability parameters. We have measured the paper smoothness and roughness, fibre orientation, formation index, surface energy, penetration dynamics and coefficient of friction were determined for runnability and additionally print gloss, mottling and ink rubbing were determined to test printability and durability. From the measured paper properties surface roughness/smoothness, surface energy and short time limit liquid absorption had the largest correlation with printability parameters, while the coefficient of friction and formation index did not correlate with the printability and convertibility parameters. All samples were printable with water-based flexo printing technology. Samples with lower surface energy had lower porosity and liquid penetration was slower, while samples with higher surface energy were more porous, which resulted in higher print gloss. These characteristics influenced the colour differences where consequently where the highest colour difference after ink rubbing had the Jute fibre paper which had low surface energy and porosity.

Graphical abstract

Similar content being viewed by others

References

Ashori A (2006) Nonwood fibers—a potential source of raw material in papermaking. Polym-Plast Technol 45(10):1133–1136. https://doi.org/10.1080/03602550600728976

Abd El-Sayed E, El-Sakhawy M, El-Sakhawy M (2020) Non-wood fibres as raw materials for the pulp and paper industry. Nord Pulp Pap Res J 35(2):215–230. https://doi.org/10.1515/npprj-2019-0064

Aspler, J. S. (1993). Interactions of ink and water with the paper surface in printing. Nord Pulp Paper Res J 8(1):68–74, 112

Argent D, Patterson C, Field S, Gilbert S, Sickinger G (1999) Flexography: principles & practices, 5th edn., vol 5. Foundation of Flexographic Technical Association, Ronkonkoma, pp 1–120

Back EL (1991) Paper to paper and paper to metal friction. In: Proc, 1991 int. paper physics conference, Kona, Hawaii, vol 2. TAPPI Press, Atlanta, pp 49–65

Bernié J-P, Douglas WJM (1996) Local grammage distribution and formation of paper by light transmission image analysis. Tappi J 79(1):193–202

Bernié J-P, Journeaux IA, Stolarz JW, Douglas WJM (2000) Prediction of print quality using the components of formation of unprinted paper. In: 2000 international printing & graphic arts conference proceedings

Comyn J, Philippe C (2006) Chapter 1 theories of adhesion. In: Handbook of adhesives and sealants, vol 2. Elsevier, Technology and Engineering, pp 1–50

Corson RS, Flowers GA, Morgan GD, Richardson D, J, (2004) Paper structure and printability as controlled by the fibrous elements. Tappi J 3(6):14–18

Černič M (2008) Trajnost in obstojnost dokumentnega gradiva na papirju. PhD thesis. [M. Černič], Ljubljana, p 263

Dedijer S, Jurič I, Tomić I, Pál M, Milic N (2018) Preliminary study of print mottle analysis in flexography using GLCM method. In: April 2018 conference: innovations in publishing, printing and multimedia technologies, Kaunas, Lithuania

Fellers C, Backstrom M, Htun M, Lindholm G (1998) Paper-to-paper friction—paper structure and moisture. Nord Pulp Paper Res J 13(3):225–232. https://doi.org/10.3183/npprj-1998-13-03-p225-232

Ferdous T, Ni Y, Quaiyyum MA, Uddin MN, Jahan MS (2021) Non-wood fibers: relationships of fiber properties with pulp properties. ACS Omega 6(33):21613–21622. https://doi.org/10.1021/acsomega.1c02933

Favero A, Thomas VM, Luettgen C (2017) Life cycle and market review of the major alternative fibres for paper production. Georgia Institute of Technology. https://greenseal.org/wp-content/uploads/2018/07/Life-Cycle-and-Market-Review-of-Major-Alternative-Fibers-for-Paper-Production.-April-2017.pdf. Accessed 12 Nov 2021

Fulleringer N (2014) Contribution to the study of friction phenomena: application to paper materials. Materials, Université de Grenoble. English. ffNNT: 2014GRENI071ff. tel-01153587f

Gaertner M, Wilson JRU, Cadotte MW et al (2017) Non-native species in urban environments: patterns, processes, impacts and challenges. Biol Invasions 19:3461–3469. https://doi.org/10.1007/s10530-017-1598-7

Johnson J (2008) Aspects of flexographic print quality and relationship to some printing parameters. Dissertation, Karlstad University, Karlstadt. ISBN 978-91-7063-187-0

Garoff N, Nilvebrant N-O, Fellers C (2002) Friction of linerboard based on recycled fibre. J Appl Polym Sci 85:1511–1520. https://doi.org/10.1002/app.10783

Grigaliuniene S, Sidaravicius J, Turla V, Kibirkstis E, Jurkonis E (2015) Investigation of the friction of flexographic and inkjet prints. Nord Pulp Paper Res J 30(3):519–526. https://doi.org/10.3183/npprj-2015-30-03-p519-526

Hoyland RW, Neill MP (1997) The effect of AKD on paper friction—prepared contribution. In: The fundamentals of papermaking materials, Trans. of the XIth Fund. Res. Symp. Cambridge. FRC, Manchester, 2018, pp 1617–1631. https://doi.org/10.15376/frc.1997.3.1617

Johansson A, Fellers C, Gunderson D, Haugen U (1991) Paper friction—influence of the measurement conditions. In: TAPPI I99I international paper physics conference proceedings, TAPPI PRESS, Atlanta, pp 49–65

Johnson J, Rättö P, Järnström L, Lestelius M, Järnström L (2005) Interaction between water and paperboard and liner in a flexographic printing press. TAGA Journal 1:110–128

Karlovits I, Lavrič GK, U, Zorić V (2021) Electrophotography toner adhesion on agro-industrial residue and invasive plant papers. J Adhes Sci Technol 35(23):2636–2651. https://doi.org/10.1080/01694243.2021.1894694

Karlovits I, Kavčič U, Lavrič G, Šinkovec A, Zorić V (2020) (2020) Digital printability of papers made from invasive plants and agro-industrial residues. Cellul Chem Technol 54(5–6):523–529

Krainer S, Hirn U (2018) Short timescale wetting and penetration on porous sheets measured with ultrasound, direct absorption and contact angle. RSC Adv 8(23):12861–12869. https://doi.org/10.1039/c8ra01434e

Kavčič U, Karlovits I (2020) The influence of process parameters of screen-printed invasive plant paper electrodes on cyclic voltammetry. Nord Pulp Paper Res J 35(2):299–307. https://doi.org/10.1515/npprj-2019-0070

Karlovits I, Kavčič UR, Lavrič GR, Šinkovec A, Zorić V (2020) Digital printability of papers made from invasive plants and agro-industrial residues. Cellul Chem Technol 54:523–529. https://doi.org/10.35812/CelluloseChemTechnol.2020.54.53

Kulachenko A, Gradin P, Uesaka T (2007) Basic mechanisms of fluting formation and retention in paper. Mech Mater 39(7):643–663

Kulachenko A, Uesaka T (2012) Direct simulations of fibre network deformation and failure. Mech Mater 51:1–14. https://doi.org/10.1016/j.mechmat.2012.03.010

Lahti J, Dauer M, Keller DS et al (2020) (2020) Identifying the weak spots in packaging paper: local variations in grammage, fibre orientation and density and the resulting local strain and failure under load. Cellulose 27:10327–10343. https://doi.org/10.1007/s10570-020-03493-z

Luu WT (2010) The setting of water-based inks on uncoated substrates. PhD thesis, Electronic Theses and Dissertations, 833. University of Maine, USA. https://digitalcommons.library.umaine.edu/etd/833

Moutihno I, Figuereido M, Ferreira P (2007) Evaluating the surface energy of laboratory-made paper sheets by contact angle measurements. Tappi J 6(6):26–32

Niskanan KJ (1989) Distribution of fibre orientations in the paper. In: Baker CF, Punton V (eds) Fundamentals of papermaking, Trans. of the IXth Fund. Res. Symp. Cambridge. FRC, Manchester, 2018, pp 275–308. https://doi.org/10.15376/frc.1989.1.275

Olsson R, Yang LQ, Lestelius M (2007) Water retention of flexographic inks and its influence on final print gloss. Nord Pulp Paper Res J 22:287–292. https://doi.org/10.3183/NPPRJ-2007-22-03-p287-292

Püspöki Z, Storath M, Sage D, Unser M (2016) Transforms and operators for directional bioimage analysis: a survey. In: De Vos W, Munck S, Timmermans JP (eds) Focus on Bio-image informatics. Advances in anatomy, embryology and cell biology, vol 219. Springer, Cham. https://doi.org/10.1007/978-3-319-28549-8_3

Przybysz K, Małachowska E, Martyniak D, Boruszewski P, Iłowska J, Kalinowska H, Przybysz P (2018) Yield of pulp, dimensional properties of fibers, and properties of paper produced from fast growing trees and grasses. BioRes 13(1):1372–1387

Sridach W (2010) The environmentally benign pulping process of non-wood fibers. Suranaree J Sci Technol 17(2):105–123

Starešinič M, Boh Podgornik B, Javoršek D, Leskovšek M, Možina K (2021) Fibers obtained from invasive alien plant species as a base material for paper production. Forests 12(5):527. https://doi.org/10.3390/f12050527

Stor-Pellinen J, Hæggström E, Luukkala M (2000) Measurement of paper-wetting processes by ultrasound transmission. Meas Sci Technol 11(4):406–411

Ström G (2005) Review: interaction between offset ink and coated paper—a review of the present understanding. In: I'Anson SJ (ed) Advances in paper science and technology, Trans. of the XVIIIth Fund. Res. Symp. Cambridge. FRC, Manchester, 2018, pp 1101–1137. https://doi.org/10.15376/frc.2005.2.1101

Szczypiński P, Strzelecki M, Materka A, Klepaczko A (2009) MaZda—a software package for image texture analysis. Comput Methods Programs Biomed 94(1):66–76. https://doi.org/10.1016/j.cmpb.2008.08.005

Tabor D (1992) Friction as a Dissipative Process. In: Singer IL, Pollock HM (eds) Fundamentals of Friction: Macroscopic and Microscopic Processes. NATO ASI Series, vol 220. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-2811-7_1

Thorman S, Ström G, Gane PAC (2018) Impact of non-uniform water absorption on water-interference print mottle in offset printing Nord. Pulp Paper Res J 33(1):150–163. https://doi.org/10.1515/npprj-2018-3011

Two Sides North America (2020) Wood-based paper and alternative fiber-based paper. The Facts, https://twosidesna.org/wp-content/uploads/sites/16/2021/03/Two-Sides-Alternative-Fibers-Fact-Sheet-Dec-2020-FINAL2.pdf

Yang L, Liu J, Lu G (2013) Detailed insights to liquid absorption and liquid-paper interaction. In: I’Anson SJ (ed) Advances in pulp and paper research, Cambridge, Trans. of the XVth Fund. Res. Symp. Cambridge. FRC, Manchester, 2018, pp 585–598. https://doi.org/10.15376/frc.2013.2.585.

Zang YH, Aspler JS (1995) Factors that affect the flexographic printability of linerboards. Tappi J 78(10):223–240

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Karlovits, I., Kavčič, U. Flexo printability of agro and invasive papers. Cellulose 29, 4613–4627 (2022). https://doi.org/10.1007/s10570-022-04571-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04571-0