Abstract

Nanoparticle spray deposition finds numerous applications in pharmaceutical, electronics, manufacturing, and energy industries and has shown great promises in engineering the functional properties of the coated parts. However, current spray deposition systems either lack the required precision in controlling the morphology of the deposited nanostructures or do not have the capacity for large-scale deposition applications. In this study, we introduce a novel spray system that uses supercritical CO2 to assist the atomization process and create uniform micron-size water droplets that are used as cellulose nanocrystal (CNC) carriers. CNCs are selected in this study as they are abundant, possess superior mechanical properties, and contain hydroxyl groups that facilitate interaction with neighboring materials. We fundamentally investigate the effect of different process parameters, such as injection pressure, gas-to-liquid ratio, the axial distance between the nozzle and substrate, and CNC concentration on the final patterns left on the substrate upon evaporation of water droplets. To this end, we show how tuning process parameters control the size of carrier droplets, dynamics of evaporation, and self-assembly of CNCs, which in turn dictate the final architecture of the deposited nanostructures. We will particularly investigate the morphology of the nanostructures deposited after evaporation of micron-size droplets that has not been fully disclosed to date. Different characterization techniques such as laser diffraction, polarized microscopy, and high-resolution profilometry are employed to visualize and quantify the effect of each process parameter. Numerical simulations are employed to inform the design of experiments. Finally, it is shown that the fabricated nanostructures can be engineered based on the size of the carrier droplets controlled by adjusting spray parameters and the concentration of nanoparticles in the injected mixture. Process parameters can be selected such that nanoparticles form a ring, disk, or dome-shaped structure. Moderate operational conditions, simplicity, and time efficiency of the process, and use of abundant and biodegradable materials, i.e., water, CNCs, and CO2 promote the scalability and sustainability of this method.

Similar content being viewed by others

Data availability

All the data and materials supporting the claims herein are included in the manuscript and comply with the field standards.

References

Aguiar-Ricardo A (2017) Building dry powder formulations using supercritical CO2 spray drying. Current Opini Green Sustain Chem 5:12–16

Andrews SW, Nover DM, Reuter JE, Schladow SG (2011) Limitations of laser diffraction for measuring fine particles in oligotrophic systems: pitfalls and potential solutions. Water Resourc Res. https://doi.org/10.1029/2010WR009841

Anyfantakis M, Geng Z, Morel M, Rudiuk S, Baigl D (2015) Modulation of the coffee-ring effect in particle/surfactant mixtures: the importance of particle–interface interactions. Langmuir 31:4113–4120

Azarova NA, Owen JW, McLellan CA, Grimminger MA, Chapman EK, Anthony JE, Jurchescu OD (2010) Fabrication of organic thin-film transistors by spray-deposition for low-cost, large-area electronics. Org Electron 11:1960–1965

Bachu S, Brant Bennion D (2009) Interfacial tension between CO2, freshwater, and brine in the range of pressure from (2 to 27) MPa, temperature from (20 to 125) C, and water salinity from (0 to 334 000) mg· L− 1. J Chem Eng Data 54:765–775

Barbezat G (2005) Advanced thermal spray technology and coating for lightweight engine blocks for the automotive industry. Surface Coatings Tech 200:1990–1993

Bouse LF, Kirk IW, Bode LE (1990) Effect of spray mixture on droplet size. Trans ASAE 33:783–0788

Bugakova D, Slabov V, Sergeeva E, Zhukov M, Vinogradov AV (2019) Comprehensive characterization of TiO2 inks and their application for inkjet printing of microstructures. Colloids Surf a: Physicochem Eng Aspects 586:124146

Calvert P (2001) Inkjet printing for materials and devices. Chem Mater 13:3299–3305

Costa C, Casimiro T, Aguiar-Ricardo A (2018) Optimization of supercritical CO2-assisted atomization: phase behavior and design of experiments. J Chem Eng Data 63:885–896

Cui L, Zhang J, Zhang X, Li Y, Wang Z, Gao H, Wang T, Zhu S, Hailing Yu, Yang B (2012) Avoiding coffee ring structure based on hydrophobic silicon pillar arrays during single-drop evaporation. Soft Matter 8:10448–10456

Dayal P, Shaik MS, Singh M (2004) Evaluation of different parameters that affect droplet-size distribution from nasal sprays using the Malvern Spraytec®. J Pharm Sci 93:1725–1742

Deegan RD, Bakajin O, Dupont TF, Huber G, Nagel SR, Witten TA (1997) Capillary flow as the cause of ring stains from dried liquid drops. Nature 389:827

Della Porta G, De Vittori C, Reverchon E (2005) Supercritical assisted atomization: a novel technology for microparticles preparation of an asthma-controlling drug. AAPS PharmSciTech 6(E421):E428

Diamond L, Akinfiev N (2003) Solubility of CO2 in water from −1.5 to 100 °C and from 0.1 to 100 MPa: evaluation of literature data and thermodynamic modelling. Fluid Phase Equilib 208:265–290

Dicuangco M, Dash S, Weibel JA, Garimella SV (2014) Effect of superhydrophobic surface morphology on evaporative deposition patterns. Appl Phys Lett 104:201604

Dinh NT, Sowade E, Blaudeck T, Hermann S, Rodriguez RD, Zahn DRT, Schulz SE, Baumann RR, Kanoun O (2016) High-resolution inkjet printing of conductive carbon nanotube twin lines utilizing evaporation-driven self-assembly. Carbon 96:382–393

Fauchais P, Vardelle M, Vardelle A, Goutier S (2015) What do we know, what are the current limitations of suspension plasma spraying? J Therm Spray Technol 24:1120–1129

Fauchais PL, Joachim VR, Heberlein, Maher IB (2014) 'Wire arc spraying' In: Thermal Spray Fundamentals. Springer, Berlin

Goth C, Sonja P, Joerg F (2011) "Aerosol Jet printing on rapid prototyping materials for fine pitch electronic applications." In 2011 IEEE 61st Electronic components and technology conference (ECTC), 1211–16. IEEE

Govor LV, Reiter G, Bauer GH, Parisi J (2004) Nanoparticle ring formation in evaporating micron-size droplets. Appl Phys Lett 84:4774–4776

Grishkewich N, Mohammed N, Tang J, Tam KC (2017) Recent advances in the application of cellulose nanocrystals. Current Opinion in Colloid Interface Science 29:32–45

Gu M, Jiang C, Liu D, Prempeh N, Smalyukh II (2016) Cellulose nanocrystal/poly (ethylene glycol) composite as an iridescent coating on polymer substrates: structure-color and interface adhesion. ACS Applied Materials Interfaces 8:32565–32573

Hu H, Larson RG (2002) Evaporation of a sessile droplet on a substrate. J Phys Chem B 106:1334–1344

Hu H, Larson RG (2005) Analysis of the microfluid flow in an evaporating sessile droplet. Langmuir 21:3963–3971

Huang S, Vignolles M-L, Chen XD, Le Loir Y, Jan G, Schuck P, Jeantet R (2017) Spray drying of probiotics and other food-grade bacteria: A review. Trends in Food Sci Tech 63:1–17

Jabari E, Ehsan %J Carbon Toyserkani. (2015) Micro-scale aerosol-jet printing of graphene interconnects. Carbon 91:321–329

Jarrahbashi D, Sirignano WA (2014) Vorticity dynamics for transient high-pressure liquid injection. Phys Fluids 26:101304

Jarrahbashi D, Sirignano WA, Popov PP, Hussain F (2016) Early spray development at high gas density: hole, ligament and bridge formations. J Fluid Mech 792:186–231

Jarrahbashi D, Kim S, Genzale CL (2017a) Simulation of combustion recession after end-of-injection at diesel engine conditions. J Eng Gas Turbines Power 139:102804-04–102808

Jarrahbashi D, Kim S, Knox BW, Genzale CL (2017b) Computational analysis of end-of-injection transients and combustion recession. Int J Engine Res 18:1088–1110

Ke D, Vu AA, Bandyopadhyay A, Bose S (2019) Compositionally graded doped hydroxyapatite coating on titanium using laser and plasma spray deposition for bone implants. Acta Biomater 84:414–423

Krebs FC (2009) Fabrication and processing of polymer solar cells: a review of printing and coating techniques. Solar Energy Mater Solar Cells 93:394–412

Kuroda S, Kawakita J, Watanabe M, Kim KH, Molak R, Katanoda H (2015) 'Current status and future prospects of warm spray technology.' In: Future development of thermal spray coatings. Elsevier, Armsterdam

Kuznetsov IA, Greenfield MJ, Mehta YU, Merchan-Merchan W, Salkar G, Saveliev AV (2011) Increasing the solar cell power output by coating with transition metal-oxide nanorods. Appl Energy 88:4218–4221

Le Hue P (1998) Progress and trends in ink-jet printing technology. J Imaging Sci Tech 42:49–62

Lu G, Han H, Duan Y, Sun Y (2013) Wetting kinetics of water nano-droplet containing non-surfactant nanoparticles: a molecular dynamics study. Appl Phys Lett 103:253104

Lu S, Zheng J, Cardenas JA, Williams NX, Lin Y-C, Franklin AD (2020) Uniform and stable aerosol jet printing of carbon nanotube thin-film transistors by ink temperature control. ACS Appl Mater Interf 12:43083–43089

Mahajan A, Daniel Frisbie C, Francis LF (2013) Optimization of aerosol jet printing for high-resolution, high-aspect ratio silver lines. ACS Appl Mater Interf 5:4856–4864

Mampallil D, Eral HB (2018) A review on suppression and utilization of the coffee-ring effect. Adv Colloid Interface Sci 252:38–54

Mampallil D, Reboud J, Wilson R, Wylie D, Klug DR, Cooper JM (2015) Acoustic suppression of the coffee-ring effect. Soft Matter 11:7207–7213

Mariano M, El Kissi N, Dufresne A (2014) Cellulose nanocrystals and related nanocomposites: review of some properties and challenges. J Polym Sci, Part b: Polym Phys 52:791–806

Markt DP, Roberto T, Ashish P, Mehdi R, Sibendu S, Riccardo S, Seong-Young L, Jeffrey N (2018) "Using a DNS framework to test a splashed mass sub-model for Lagrangian spray simulations." In: SAE Technical Paper

Mette A, Richter PL, Hörteis M, Glunz SW (2007) Metal aerosol jet printing for solar cell metallization. Prog Photovolt: Res Appl 15:621–627

Mishra R, Christopher R (2019) "Evaluating surface film models for multi-dimensional modeling of spray-wall interaction." In.: SAE Technical Paper

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Moridi A, Hassani-Gangaraj SM, Guagliano M, Dao M (2014) Cold spray coating: review of material systems and future perspectives. Surf Eng 30:369–395

Nguyen TAH, Nguyen AV (2012) Increased evaporation kinetics of sessile droplets by using nanoparticles. Langmuir 28:16725–16728

Palaganas NB, Mangadlao JD, de Leon AC, Palaganas JO, Pangilinan KD, Lee YJ, Advincula RC (2017) 3D printing of photocurable cellulose nanocrystal composite for fabrication of complex architectures via stereolithography. ACS Appl Mater Interf 9:34314–34324

Parker RM, Frka-Petesic B, Guidetti G, Kamita G, Consani G, Abell C, Vignolini S (2016) Hierarchical self-assembly of cellulose nanocrystals in a confined geometry. ACS Nano 10:8443–8449

Parker RM, Guidetti G, Williams CA, Zhao T, Narkevicius A, Vignolini S, Frka-Petesic B (2018) The self-assembly of cellulose nanocrystals: hierarchical design of visual appearance. Adv Mater 30:1704477

Paulsen JA, Michael R, Kurt C, Richard P (2012) "Printing conformal electronics on 3D structures with Aerosol Jet technology." In 2012 Future of Instrumentation International Workshop (FIIW) Proceedings, 1–4. IEEE

Pawlowski L (2008) The science and engineering of thermal spray coatings. Wiley, New Jersey

Phan HT, Caney N, Marty P, Colasson S, Gavillet J (2009) Surface wettability control by nanocoating: the effects on pool boiling heat transfer and nucleation mechanism. Int J Heat Mass Transf 52:5459–5471

Ranz WE, Marshall WR (1952) Evaporation from drops. Chem Eng Prog 48:141–146

Reitz RD (1987) Modeling atomization processes in high-pressure vaporizing sprays. Atomizat Spray Tech 3:309–337

Reverchon E (2002) Supercritical-assisted atomization to produce micro-and/or nanoparticles of controlled size and distribution. Ind Eng Chem Res 41:2405–2411

Reverchon, Ernesto. 2007. "Process for the production of micro and/or nano particles." In.: Google Patents.

Rie V, Jonas CS, Gençer A, Lombardo S, Gasser U, Kumar S, Salazar-Alvarez G, Kang K, Thielemans W (2019) Anisotropic diffusion and phase behavior of cellulose nanocrystal suspensions. Langmuir 35:2289–2302

Roman, Maren, Shuping Dong, Anjali Hirani, and Yong Woo Lee. 2009. 'Cellulose nanocrystals for drug delivery.' in (ACS Publications).

Sarobol P, Cook A, Clem PG, Keicher D, Hirschfeld D, Hall AC, Bell NS (2016) Additive manufacturing of hybrid circuits. Annu Rev Mater Res 46:41–62

Secor EB (2018) Principles of aerosol jet printing. Flex Print Electron 3:35002

Seifert T, Sowade E, Roscher F, Wiemer M, Gessner T, Baumann RR (2015) Additive manufacturing technologies compared: morphology of deposits of silver ink using inkjet and aerosol jet printing. Ind Eng Chem Res 54:769–779

Shariati A, Peters CJ (2003) Recent developments in particle design using supercritical fluids. Current Opin Solid State Mater Sci 7:371–383

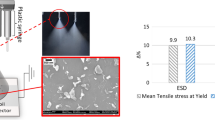

Shariatnia S, Akshaj V, Suleiman O, Dorrin J, Amir A (2019) Atomization of cellulose nanocrystals aqueous suspensions in fused deposition modeling: A scalable technique to improve the strength of 3D printed polymers. Composit Part B Eng 177:107291

Shariatnia S, Annuatha VK, Ozge K, Amir A (2020) Hybrid cellulose nanocrystals-bonded carbon nanotubes/carbon fiber polymer composites for structural applications. ACS Appl Nano Mater 3(6):5421–5436

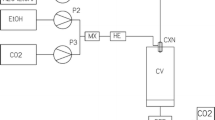

Shariatnia S, Amir A, Dorrin J (2021) Experimental analysis of supercritical-assisted atomization. PhysFluId 33:013314

Singh A, den Guy VM (2016) Spray drying formulation of amorphous solid dispersions. Adv Drug Deliver Review 100:27–50

Stanton, Donald W, and Christopher J Rutland. 1996. 'Modeling fuel film formation and wall interaction in diesel engines', SAE transactions: 808–24.

Stanton D, Rutland C (1996a) Modeling fuel film formation and wall interaction in diesel engines. SAE Technical Paper. https://doi.org/10.4271/960628

Tang J, Sisler J, Grishkewich N, Tam KC (2017) Functionalization of cellulose nanocrystals for advanced applications. J Coll Interf Sci 494:397–409

Tewes F, Boury F (2005) Formation and rheological properties of the supercritical CO2− water pure interface. J Phys Chem B 109:3990–3997

Tom JW, Debenedetti PG (1991) Particle formation with supercritical fluids—a review. J Aerosol Sci 22:555–584

Tsang C-W, Trujillo MF, Rutland CJ (2014) Large-eddy simulation of shear flows and high-speed vaporizing liquid fuel sprays. Comput Fluids 105:262–279

Vehring R (2008) Pharmaceutical particle engineering via spray drying. Pharm Res 25:999–1022

Weast RC, MJ CRC, Astle, Boca Raton, Fla. 1981. 'CRC Handbook of chemistry and physics 62nd ed'

Wei Y (2015) 'Effect of particles on evaporation of droplet containing particles'

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18(293):297

Weller HG, Tabor G, Jasak H, Fureby C (1998) A tensorial approach to computational continuum mechanics using object-oriented techniques. Comput Phys 12:620–631

Wilkinson NJ, Smith MAA, Kay RW, Harris RA (2019) A review of aerosol jet printing—a non-traditional hybrid process for micro-manufacturing. Int J Adv Manuf Tech 105:4599–4619

Yunker PJ, Still T, Lohr MA, Yodh AG (2011) Suppression of the coffee-ring effect by shape-dependent capillary interactions. Nature 476:308–311

Zhao Da, Liu T, Park JG, Zhang M, Chen J-M, Wang B (2012) Conductivity enhancement of aerosol-jet printed electronics by using silver nanoparticles ink with carbon nanotubes. Microelectron Eng 96:71–75

Zuo B, Gomes AM, Rutland CJ (2000) Studies of superheated fuel spray structures and vaporization in GDI engines. Int J Engine Res 1(4):321–336

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shariatnia, S., Jangale, P., Mishra, R. et al. Supercritical CO2-assisted atomization for deposition of cellulose nanocrystals: an experimental and computational study. Cellulose 29, 1–22 (2022). https://doi.org/10.1007/s10570-021-04368-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-04368-7