Abstract

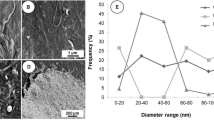

This work evaluates the effect of spray-coating papers using cellulose nanofibrils (CNFs) and nanoclay (NC) on the mechanical and barrier properties for application such as reinforced packaging bags. Sack kraft papers of 60 g m−2 (C60) were coated with combinations of CNFs and CNFs + NC, varying the number of layers on the internal face (IF) and external face (EF) of the paper. Their properties were compared to uncoated sack kraft papers with basis weight of 60 g m−2 (C60), 80 g m−2 (C80) and 120 g m−2 (C120). The amount of CNF/NC deposited was ~ 20 g m−2 while the CNF layer deposited was ~ 10 g m−2 on the sack papers. Increase in the number of layers deposited decreased the water vapor transmission rate (WVTR) compared to C60. CNF layer had lower contact angles on the coated papers than CNF/NC layer. The coated papers also showed a 44–66% increase in tensile index when compared to C120. Papers coated with 2 layers of CNFs and 1 layer of CNFs /NC achieved the same tensile index as C120 and the layers also resulted in higher values of Young’s modulus (38–56%) when compared to C60. Spray-coating, with the appropriate layers, improved the mechanical and barrier properties of the coated papers, and is a possible alternative to producing papers with lower basis weight and using renewable raw materials. Additionally, the mixture of two hydrophilic components, such as nanofibrils and NC can result in a coating with more hydrophobic characteristics.

Similar content being viewed by others

References

Abdullah MMAB, Ming LY, Yong HC, Tahir MFM (2018) Clay-based materials in geopolymer technology. Cem-Based Mater Intechopen. https://doi.org/10.5772/intechopen.74438

Afra E, Mohammadnejad S, Saraeyan A (2016) Cellulose nanofibils as coating material and its effects on paper properties. Progr Organic Coat 101:455–460

American Society for Testing and Materials - ASTM D645M-97 (2007) Standard test method for thickness of paper and paperboard (Withdrawn 2010). ASTM International, West Conshohocken, PA, USA

American Society for Testing and Materials - ASTM D646–96 (1996) Standard test method for grammage of paper and paperboard (mass per unit area). ASTM International, West Conshohocken, PA, USA

American Society for Testing and Materials - ASTM D828–97 (2002) Standard test method for tensile properties of paper and paperboard using constant-rate-of-elongation apparatus (Withdrawn 2009). ASTM International, West Conshohocken, PA, USA

American Society for Testing and Materials - ASTM E96/E96M-16 (2016) Standard test methods for water vapor transmission of materials. ASTM International, West Conshohocken, PA, USA

Bardet R et al (2015) Substitution of nanoclay in high gas barrier films of cellulose nanofibrils with cellulose nanocrystals and thermal treatment. Cellulose 22:1227–1241

Beneventi D, Chaussy D, Curtil D, Zolin L, Gerbaldi C, Penazzi N (2014) Highly porous paper loading with microfibrillated cellulose by spray coating on wet substrates. Ind Eng Chem Res 53:10982–10989

Brodin FW, Gregersen ØW, Syverud K (2014) Cellulose nanofibrils: challenges and possibilities as a paper additive or coating material - a review. Nord Pulp Pap Res J 29:156–166

Bufalino L, de Sena Neto AR, Tonoli GHD, de Souza FA, Costa TG, Marconcini JM, Colodette JL, Labory CRG, Mendes LM (2015) How the chemical nature of Brazilian hardwoods affects nanofibrillation of cellulose fibers and film optical quality. Cellulose 22:3657–3672

Cao B, Tschirner U, Ramaswamy S (1999) A study of changes in wet-fiber flexibility and surface condition of recycled fibers. Paperi Ja Puu-Pap. Timber 81:117–122

Chen YW, Lee HV, Juan JC, Siew-Moi P (2016) Production of new cellulose nanomaterial from red algae marine biomass Gelidium elegans. Carbohyd Polym 151:1210–1219

Chinnama PR, Mantravadia R, Jimeneza JC, Dikinb DA, Wundera SL (2016) Lamellar, micro-phase separated blends of methyl cellulose and dendritic polyethylene glycol. Carbohyd Polym 136:19–29

Corral ML, Cerrutti P, Vázquez A, Califano A (2017) Bacterial nanocellulose as a potential additive for wheat bread. Food Hydrocol 67:189–196

Dias MC, Mendonça MC, Damásio RAP, Zidanes UL, Mori FA, Ferreira SR, Tonoli GHD (2019) Influence of hemicellulose content of Eucalyptus and Pinus fibers on the grinding process for obtaining cellulose micro/nanofibrils. Holzforsch 73:1035–1046

do Lago RC, de Oliveira ALM, Dias MC, de Carvalho EEN, Tonoli GHD, Vilas Boas EVB, 2020do Lago RC, de Oliveira ALM, Dias MC, de Carvalho EEN, Tonoli GHD, Vilas Boas EVB (2020) Obtaining cellulosic nanofibrils from oat straw for biocomposite reinforcement: Mechanical and barrier properties. Ind Crop Prod 148: 112264

Dufresne A (2013) Nanocellulose: A new ageless bionanomaterial. Mater Today 16:220–227

Durães AFS, Moulin JC, Dias MC, Mendonça MC, Damásio RAP, Thygesen LG, Tonoli GHD (2020) Influence of chemical pretreatments on plant fiber cell wall and their implications on the appearance of fiber dislocations. Holzforsch 74:949–955

Ferreira SR, de Silva F, A, Lima PRL, Toledo Filho RD, (2017) Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and curauá fiber cement based composite systems. Const Build Mat 139:551–561

Floody MC, Theng BKG, Reyes P (2009) Natural nanoclays: applications and future trends - a Chilean perspective. Clay Miner 1:161–176

Fonseca CS, Silva TF, Silva MF, Oliveira IRC, Mendes RF, Hein PRG, Mendes LM, Tonoli GHD (2016) Eucalyptus cellulose micro/nanofibrils in extruded fibercement composites. Cerne 22:59–68

Fonseca AS, Panthapulakkal S, Konar SK, Sain M, Bufalino L, Raabe J, Miranda IPA, Martins MA, Tonoli GHD (2019) Improving cellulose nanofibrillation of non-wood fiber using alkaline and bleaching pre-treatments. Ind Crop Prod 131:203–212

Fonseca CS, Scatolino MV, Silva LE, Martins MA, Guimarães Júnior M, Tonoli GHD (2021) Valorization of jute biomass: performance of fiber-cement composites extruded with hybrid reinforcement (fibers and nanofibrils). Waste Biomass Valor. https://doi.org/10.1007/s12649-021-01394-1

Gabr MH, Phong NT, Abdelkareem MA, Okubo K, Uzawa K, Kimpara I, Fujii T (2013) Mechanical, thermal, and moisture absorption properties of nano-clay reinforced nano-cellulose biocomposites. Cellulose 20:819–826

Gaikwad KK, Seonghyuk KO (2014) Overview on in polymer-nano clay composite paper coating for packaging application. J Mater Sci Eng 4:1–5

García A, Gandini A, Labidi J, Belgacem N, Bras J (2016) Industrial and crop wastes: a new source for nanocellulose biorefinery. Ind Crop Prod 93:26–38

Guimarães M Jr, Botaro VR, Novack KM, Flauzino Neto WP, Mendes LM, Tonoli GHD (2015) Preparation of cellulose nanofibrils from bamboo pulp by mechanical defibrillation for their applications in biodegradable composites. J Nanosci Nanotechnol 15:6751–6768

Guimarães M Jr, Teixeira FG, Tonoli GHD (2018) Effect of the nano-fibrillation of bamboo pulp on the thermal, structural, mechanical and physical properties of nanocomposites based on starch/poly(vinyl alcohol) blend. Cellulose 25:1823–1849

Guimarães BMR, Scatolino MV, Martins MA et al (2021) Bio-based films/nanopapers from lignocellulosic wastes for production of added-value micro-/nanomaterials. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-021-16203-4

Heidari A, Sayadi MH, Atigh ZBQ (2021) Comparative study of different materials (drinking water treatment sludge, nanoclay, and modified nanoclay) for simultaneous removal of hexavalent chromium and lead. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-020-03074-4

Herrera MA, Sirviö JA, Mathew AP, Oksman K (2016) Environmentally friendly and sustainable gas barrier on porous materials: nanocellulose coatings prepared using spin- and dip-coating. Mater Design 93:19–25

Hubbe MA, Rojas OJ, Lucia LA, Jung TM (2007) Consequences of the nanoporosity of cellulosic fibers on their streaming potential and their interactions with cationic polyelectrolytes. Cellulose 14:655–671

Jayrajsinh S, Shankar G, Agrawal YK, Bakre L (2017) Montmorillonite nanoclay as a multifaceted drug-delivery carrier: a review. J Drug Deliv Sci Technol 39:200–209

Jung YH, Tzu-Hsuan C, Zhang H, Yao C, Zheng Q, Yang VW, Mi H, Kim M, Cho SJ, Dong-Wook P (2015) High-performance green flexible electronics based on biodegradable cellulose nanofibril paper. Nat Commun 6:1–11

Kausar A (2020) Flame retardant potential of clay nanoparticles. Clay Nanoparticles. https://doi.org/10.1016/b978-0-12-816783-0.00007-4

Krishnan KA, Jose C, Rohith KR, George KE (2015) Sisal nanofibril reinforced polypropylene/polystyrene blends: Morphology, mechanical, dynamic mechanical and water transmission studies. Ind Crop Prod 71:173–184

Kumar V, Elfving A, Koivula H, Bousfield D, Toivakka M (2016) Roll-to-roll processed cellulose nanofiber coatings. Ind Engin Chem Res 55:3603–3613

Lavoine N, Desloges I, Khelifi B, Bras J (2014) Impact of different coating processes of microfibrillated cellulose on the mechanical and barrier properties of paper. J Mater Sci 49:2879–2893

Lavoine N, Guillard V, Desloges I, Gontard N, Bras J (2016) Active bio-based food-packaging: Diffusion and release of active substances through and from cellulose nanofiber coating toward food-packaging design. Carbohyd Polym 49:40–50

Leszczyńska A, Njuguna J, Pielichowski K, Banerjee JR (2007) Polymer/montmorillonite nanocomposites with improved thermal properties: part II. thermal stability of montmorillonite nanocomposites based on different polymeric matrixes. Thermochim Acta 454:1–22

Li T, Fan J, Chen W, Shu J, Qian X, Wei H, Wang Q, Shen J (2016) Coaggregation of mineral filler particles and starch granules as a basis for improving filler-fiber interaction in paper production. Carbohyd Polym 149:20–27

Lin J, Yu L, Tian F, Zhao N, Li X, Bian F, Wang J (2014) Cellulose nanofibrils aerogels generated from jute fibers. Carbohyd Polym 109:35–43

Lu P, Xiao H, Pan Y (2015) Improving Water Vapor Barrier of Green-Based Nanocellulose Film via Hydrophobic Coating. World scientific 2014 International conference on materials science and energy engineering (CMSEE 2014) - Mater Sci Energ Eng (CMSEE 2014) - 148–153

Majeed K, Jawaid M, Hassan A, Abu Bakar A, Abdul Khalil HPS, Salema AA, Inuwa I (2013) Potential materials for food packaging from nanoclay/natural fibres filled hybrid composites. Mater Des 46:391–410

Mirmehdi S, Hein PRG, Sarantópoulos CIGL, Dias MV, Tonoli GHD (2018) Cellulose nanofibrils/nanoclay hybrid composite as a paper coating: effects of spray time, nanoclay content and corona discharge on barrier and mechanical properties of the coated papers. Food Packag Shelf Life 15:87–94

Missoum K, Martoïa F, Belgacem MN, Bras J (2013) Effect of chemically modified nanofibrillated cellulose addition on the properties of fiber-based materials. Ind Crop Prod 48:98–105

Moghri M, Zanjanijam GH, AR, (2018) Prediction of barrier properties of HDPE/PA-6/nanoclay composites by response surface approach: effects of compatibilizer type and the contents of nanoclay, PA-6 and compatibilizer. Polym Bullet 75:2751–2767

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 7:3369–4260

Murray HH (2006) Structure and composition of the clay minerals and their physical and chemical properties. applied clay mineralogy - occurrences, processing and application of kaolins, bentonites, palygorskite-sepiolite, and common clays. Develop Clay Sci. https://doi.org/10.1016/s1572-4352(06)02002-2

Ogihara H, Xie J, Saji T (2015) Controlling surface energy of glass substrates to prepare superhydrophobic and transparent films from silica nanoparticle suspensions. J colloid Interf Sci 437:24–27

Pacaphol K, Aht-Ong D (2017) Preparation of hemp nanofibers from agricultural waste by mechanical defibrillation in water. J Clean Prod 142:1283–1295

Petroudy SRD, Garmaroody ER, Rudi H (2017) Oriented cellulose nanopaper (OCNP) based on bagasse cellulose nanofibrils. Carbohyd Polym 157:1883–1891

Pulikkalparambil H, Parameswaranpillai J, George JJ, Yorseng K, Siengchin S (2017) Physical and thermo-mechanical properties of bionano reinforced poly (butylene adipate-co-terephthalate), hemp/CNF/Ag-NPs composites. AIMS Mater Sci 4:814–831

Rodionova G, Lenes M, Eriksen O, Gregersen O (2011) Surface chemical modification of microfibrillated cellulose: improvement of barrier properties for packaging applications. Cellulose 18:127–134

Scatolino MV, Bufalino L, Mendes LM, Guimarães Júnior M, Tonoli GHD (2017) Impact of nanofibrillation degree of eucalyptus and Amazonian hardwood sawdust on physical properties of cellulose nanofibril films. Wood Sci Technol 51:1095–1115

Scatolino MV, Fonseca CS, da Silva GM, Rompa VD, Martins MA, Tonoli GHD, Mendes LM (2018) How the surface wettability and modulus of elasticity of the Amazonian paricá nanofibrils films are affected by the chemical changes of the natural fibers. Eur J Wood Wood Prod 76:1581–1594

Scatolino MV, Dias MC, Silva DW, Bufalino L, Martins MA, Piccoli RH, Tonoli GHD, Londero AA, Neto VO, Mendes LM (2019) Tannin-stabilized silver nanoparticles and citric acid added associated to cellulose nanofibrils: effect on film antimicrobial properties. SN Appl Sci 1:1243

Shanmugam K, Varanasi S, Garnier G, Batchelor W (2017) Rapid preparation of smooth nanocellulose films using spray coating. Cellulose 24:2669–2676

Silva LE, Santos AA, Torres L, McCaffrey Z, Klamczynski A, Greggory G, Sena Neto AR, Wood D, Williams T, Orts W, Damásio RAP, Tonoli GHD (2021) Redispersion and structural change evaluation of dried microfibrillated cellulose. Carbohyd Polyme 1:117165

Sundberg J, Guillermo T, Paul G (2013) Moisture induced plasticity of amorphous cellulose films from ionic liquid. Polymer 54:6555–6560

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16:75–85

Tonoli GHD, Teixeira EM, Corrêa AC, Marconcini JM, Caixeta LA, Pereira-da-Silva MA, Mattoso LHC (2012) Cellulose micro/nanofibres from Eucalyptus kraft pulp: preparation and properties. Carbohyd Polym 89:80–88

Tonoli GHD, Holtman KM, Glenn G et al (2016) Properties of cellulose micro/nanofibers obtained from eucalyptus pulp fiber treated with anaerobic digestate and high shear mixing. Cellulose 23:1239–1256

Vartiainen J, Tammelin T, Pere J, Tapper U, Harlin A (2010) Biohybrid barrier films from fluidized pectin and nanoclay. Carbohyd Polym 82:989–996

Volk N, He R, Magniez K (2015) Enhanced homogeneity and interfacial compatibility in melt-extruded cellulose nano-fibers reinforced polyethylene via surface adsorption of poly (ethylene glycol)-block-poly(ethylene) amphiphiles. Eur Polym J 72:270–281

Yuan Y, Lee RT (2013) Contact angle and wetting properties. Surface science techniques. Springer, Berlin, Heidelberg, pp 3–34

Zhang H, Bussini D, Hortal M, Elegir G, Mendes J, Jordá Beneyto M (2016) PLA coated paper containing active inorganic nanoparticles: material characterization and fate of nanoparticles in the paper recycling process. Waste Manage 52:339–345

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there is no conflict of interest regarding the submission.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Oliveira, M.L.C., Mirmehdi, S., Scatolino, M.V. et al. Effect of overlapping cellulose nanofibrils and nanoclay layers on mechanical and barrier properties of spray-coated papers. Cellulose 29, 1097–1113 (2022). https://doi.org/10.1007/s10570-021-04350-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-04350-3