Abstract

The influence of caustic mercerization (CM) and liquid ammonia (LA) treatments on the properties of reactively dyed cotton fabrics were schematically studied. The cotton fabrics were dyed using different commercial reactive dyes such as Reactive Red 2 (R2), Reactive Blue 21 (B21), and Reactive Orange 5 (O5) via industrial dyeing procedures. The dyed fabrics were then treated using 260 g·L−1 of caustic soda solution at 23 °C for 180 s and pure LA at −40 °C for 3 min in slack and tension conditions. The dyeing properties of the fabrics such as dye removal percentage, color strength, color uniformity, reflectance, and fastness properties (washing, rubbing, hot pressing and light) were examined. The changes in tensile strength, elongation, bending property, decomposition temperature, crystal structure, and surface morphology of the samples were also investigated using a tensile strength tester, thermogravimetric analyzer (TGA), scanning electron microscope (SEM), and an X-ray diffractometer (XRD). Results revealed that the fabric dyed with O5 showed the best stability in CM and LA treatment, and the color strength and color uniformity of the dyed fabrics increased extensively after both treatments, while the reflectance of the fabrics decreased. The washing and rubbing fastness of the fabrics were also improved, which was mainly attributed to the diffusion of the dye molecules inside the fibers and enhanced bonding between fiber and dye molecules. The fastness to hot pressing and light was unaffected and all the samples retained fastness rating between 4 and 5 after being post-treated with the CM and LA, respectively. The tensile strength of the fabrics improved from 287 to 291 and 301 N, and the elongation at break increased from 11 to 21.5 and 26% after CM and LA treatment in slack conditions, respectively. Additionally, the tensile strength of the fabrics improved from 287 to 312 and 330 N, and the elongation at break increased from 11 to 12% after applying tension during both treatments. However, the total bending length and total flexural rigidity of the samples slightly increased after both the treatments either treated with or without tension, which was mainly attributed to the orientation of the cellulose microfibril angle along the fiber axis. The surface morphology and X-ray diffraction examination revealed that the treated samples consisted of smooth rod-like structure and the cellulose I allomorph was converted to cellulose II and cellulose III after CM and LA treatments. This developed treatment method could have application potential within the textile wet-processing industry, as it could be used to improve the dyeing properties and mechanical properties of cotton fabrics.

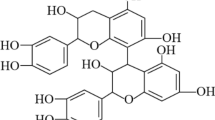

Graphic abstract

Similar content being viewed by others

Data availability

The datasets generated during the current study are available from the corresponding author on reasonable request (Prof. Yingjie Cai).

Code availability

No code was created during the current manuscript.

References

Ahmed NS, El-Shishtawy RM (2010) The use of new technologies in coloration of textile fibers. J Mater Sci 45:1143–1153. https://doi.org/10.1007/s10853-009-4111-6

Amin MN, Blackburn RS (2015) Sustainable chemistry method to improve the wash-off process of reactive dyes on cotton. ACS Sustain Chem Eng 3:725–732. https://doi.org/10.1021/acssuschemeng.5b00034

Blackburn RS, Burkinshaw SM (2002) A greener approach to cotton dyeings with excellent wash fastness. Green Chem 4:47–52. https://doi.org/10.1039/B111026H

Cai Y, Pailthorpe M, David S (1999) A new method for improving the dyeability of cotton with reactive dyes. Text Res J 69:440–446. https://doi.org/10.1177/004051759906900608

Cai Y et al (2018a) Reactive dyeing of ramie yarn washed by liquid ammonia. Cellulose 25:1463–1481. https://doi.org/10.1007/s10570-017-1645-7

Cai Y, Su S, Navik R, Wen S, Peng X, Pervez MN, Lin L (2018b) Cationic modification of ramie fibers in liquid ammonia. Cellulose 25:4463–4475. https://doi.org/10.1007/s10570-018-1905-1

Cai Y, Liang Y, Navik R, Zhu W, Zhang C, Pervez MN, Wang Q (2020) Improved reactive dye fixation on ramie fiber in liquid ammonia and optimization of fixation parameters using the taguchi approach. Dyes Pigments 183:108734. https://doi.org/10.1016/j.dyepig.2020.108734

Chen L, Liu YS, Sun WG, Zhou XY (2011) Effect of concentrated alkali treatment on the properties of naturally colored brown cotton. Adv Mat Res 332–334:173–178

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

French AD, Pérez S, Bulone V, Rosenau T, Gray D (2018) Cellulose. In: Encyclopedia of polymer science and technology, pp 1–69. https://doi.org/10.1002/0471440264.pst042.pub2

Fu S, Hinks D, Hauser P, Ankeny M (2013) High efficiency ultra-deep dyeing of cotton via mercerization and cationization. Cellulose 20:3101–3110. https://doi.org/10.1007/s10570-013-0081-6

Goda K, Sreekala M, Gomes A, Kaji T, Ohgi J (2006) Improvement of plant based natural fibers for toughening green composites—effect of load application during mercerization of ramie fibers. Compos Part A:-Appl S 37:2213–2220. https://doi.org/10.1016/j.compositesa.2005.12.014

Harrison AJ et al (2020) Recommendations for statistical analysis involving null hypothesis significance testing. Sport Biomech 19:561–568. https://doi.org/10.1080/14763141.2020.1782555

Hossain MY et al (2021) Adsorption, kinetics, and thermodynamic studies of cacao husk extracts in waterless sustainable dyeing of cotton fabric. Cellulose 28:2521–2536. https://doi.org/10.1007/s10570-020-03662-0

Hossain MY, Liang Y, Pervez MN, Ye X, Dong X, Hassan MM, Cai Y (2021) Effluent-free deep dyeing of cotton fabric with cacao husk extracts using the Taguchi optimization method. Cellulose 28:517–532. https://doi.org/10.1007/s10570-020-03525-8

Inamdar UY, Pervez MN, Navik RG, Peng X, Cai Y (2017) Low-temperature bleaching of cotton fabric by activated peroxide system. Emerg Mater Res 6:387–395. https://doi.org/10.1680/jemmr.16.00148

Karahan H, Özdoğan E, Demir A, Ayhan H, Seventekin N (2008) Effects of atmospheric plasma treatment on the dyeability of cotton fabrics by acid dyes. Color Technol 124:106–110. https://doi.org/10.1111/j.1478-4408.2008.00129.x

Karmakar SR (1999) Chemical technology in the pre-treatment processes of textiles, 1st edn. Elsevier, Amsterdam

Khatri A, Peerzada MH, Mohsin M, White M (2015) A review on developments in dyeing cotton fabrics with reactive dyes for reducing effluent pollution. J Clean Prod 87:50–57. https://doi.org/10.1016/j.jclepro.2014.09.017

Kim JT, Netravali AN (2010) Mercerization of sisal fibers: effect of tension on mechanical properties of sisal fiber and fiber-reinforced composites. Compos Part a:-Appl S 41:1245–1252. https://doi.org/10.1016/j.compositesa.2010.05.007

Lao L, Fu L, Qi G, Giannelis EP, Fan J (2017) Superhydrophilic wrinkle-free cotton fabrics via plasma and nanofluid treatment. ACS Appl Mater Inter 9:38109–38116. https://doi.org/10.1021/acsami.7b09545

Lee CH, Tang AYL, Wang Y, Kan CW (2019) Effect of reverse micelle-encapsulated reactive dyes agglomeration in dyeing properties of cotton. Dyes Pigments 161:51–57. https://doi.org/10.1016/j.dyepig.2018.09.037

Lewis DM, McIlroy KA (1997) Modification of cotton with nicotinoyl thioglycollate to improve its dyeability. Dyes Pigments 35:69–86. https://doi.org/10.1016/S0143-7208(96)00087-3

Li W et al (2018) Highly conductive copper films based on submicron copper particles/copper complex inks for printed electronics: microstructure, resistivity, oxidation resistance, and long-term stability. J Alloys Compd 732:240–247

Liu Y, Li J, Cheng X, Ren X, Huang TS (2015) Self-assembled antibacterial coating by n-halamine polyelectrolytes on a cellulose substrate. J Mater Chem B 3:1446–1454. https://doi.org/10.1039/c4tb01699h

Ma W, Zhang S, Tang B, Yang J (2005) Pretreatment of cotton with poly (vinylamine chloride) for salt-free dyeing with reactive dyes. Color Technol 121:193–197. https://doi.org/10.1111/j.1478-4408.2005.tb00272.x

Mahmud S, Pervez MN, Taher MA, Mohiuddin K, Liu HH (2020) Multifunctional organic cotton fabric based on silver nanoparticles green synthesized from sodium alginate. Text Res J 90:1224–1236. https://doi.org/10.1177/2F0040517519887532

Mittal A, Katahira R, Himmel ME, Johnson DK (2011) Effects of alkaline or liquid-ammonia treatment on crystalline cellulose: changes in crystalline structure and effects on enzymatic digestibility. Biotechnol Biofuels 4:41. https://doi.org/10.1186/1754-6834-4-41

Montazer M, Malek R, Rahimi A (2007) Salt free reactive dyeing of cationized cotton. Fiber Polym 8:608–612. https://doi.org/10.1007/BF02875997

Mouxiou E, Eleftheriadis I, Nikolaidis N, Tsatsaroni E (2008) Reactive dyeing of cellulosic fibers: use of cationic surfactants and their interaction with reactive dyes. J Appl Polym Sci 108:1209–1215. https://doi.org/10.1002/app.27705

Naikwade M, Liu F, Wen S, Cai Y, Navik R (2017) Combined use of cationization and mercerization as pretreatment for the deep dyeing of ramie. Fibre Fiber Polym 18:1734–1740. https://doi.org/10.1007/s12221-017-5512-9

Pan Y (2015) Technical research of dyeing before mercerizing process on cotton knitted fabric. Knitting Industries 4:55–57. http://en.cnki.com.cn/Article_en/CJFDTotal-ZNGU201504022.htm (in Chinese)

Patino A, Canal C, Rodríguez C, Caballero G, Navarro A, Canal JM (2011) Surface and bulk cotton fibre modifications: plasma and cationization. Influence Dye Reactive Dye Cellulose 18:1073–1083. https://doi.org/10.1007/s10570-011-9554-7

Peng X, Cai Y, Zeng Q, Hu Q, Yi C, Chen Y (2014) Adsorption behavior of reactive orange 5 and reactive red 2 on ramie fabric and their quantum chemical calculations. Fiber Polym 15:2146–2153. https://doi.org/10.1007/s12221-014-2146-z

Pervez MN, Shafiq F, Sarwar Z, Jilani MM, Cai Y (2018) Multi-response optimization of resin finishing by using a taguchi-based grey relational analysis. Materials 11:426. https://doi.org/10.3390/ma11030426

Rehan M, Mashaly HM, Mowafi S, Abou El-Kheir A, Emam HE (2015) Multi-functional textile design using in-situ Ag NPs incorporation into natural fabric matrix. Dyes Pigments 118:9–17. https://doi.org/10.1016/j.dyepig.2015.02.021

Rousselle M-A, Nelson ML (1976) Reactivity and fine structure of cotton mercerized in sodium hydroxide or liquid ammonia. Text Res J 46:648–653. https://doi.org/10.1177/004051757604600906

Saafan AA, Habib AM (1989) Pore structure of modified cotton and its effects on fiber reactive dyeing properties. Colloid Surface A 34:75–80. https://doi.org/10.1016/0166-6622(88)80083-0

Saapan A, Kandil S, Habib A (1984) Liquid ammonia and caustic mercerization of cotton fibers using X-ray, infrared, and sorption measurements. Text Res J 54:863–867. https://doi.org/10.1177/004051758405401212

Shafiq F, Pervez MN, Jilani MM, Sarwar Z, Hasani H, Cai Y (2018) Structural relationships and optimization of resin-finishing parameters using the Taguchi approach. Cellulose 25:6175–6190. https://doi.org/10.1007/s10570-018-1957-2

Skelly J (1960) The theory and practice of sodium chlorite bleaching. J Soc Dyers Colour 76:469–479. https://doi.org/10.1111/j.1478-4408.1960.tb02389.x

Su S et al (2019) Anhydrous dyeing processes of ramie fiber in liquid ammonia. Cellulose 26:8109–8120. https://doi.org/10.1007/s10570-019-02630-7

Sun Z, Zhou X, Xing Z (2016) Effect of liquid ammonia treatment on the pore structure of mercerized cotton and its uptake of reactive dyes. Text Res J 86:1625–1636. https://doi.org/10.1177/2F0040517515599746

Telegin FY, Ran JH, Morshed M, Pervez MN, Sun L, Zhang C, Priazhinikova VG (2016) Structure and properties of dyes in coloration of textiles: application of fragment approach. Key Eng Mater 703:261–266

Wakida T et al (1995) Dyeing properties of cotton fibres treated with liquid ammonia. J Soc Dyers Colour 111:154–158. https://doi.org/10.1111/j.1478-4408.1995.tb01714.x

Wakida T, Kida K, Lee M, Bae S, Yoshioka H, Yanai Y (2000) Dyeing and mechanical properties of cotton fabrics treated with sodium hydroxide/liquid ammonia and liquid ammonia/sodium hydroxide. Text Res J 70:328–332. https://doi.org/10.1177/2F004051750007000408

Wang L, Yan K, Hu C, Ji B (2020) Preparation and investigation of a stable hybrid inkjet printing ink of reactive dye and CHPTAC. Dyes Pigments 181:108584. https://doi.org/10.1016/j.dyepig.2020.108584

Wen L, Lei W-g, Ren C (2006) Effect of volume fraction of ramie cloth on physical and mechanical properties of ramie cloth/UP resin composite. T Nonferr Metal Soc 16:s474–s477. https://doi.org/10.1016/S1003-6326(06)60237-9

Yang D-F, Kong X-J, Gao D, Cui H-S, Huang T-T, Lin J-X (2017) Dyeing of cotton fabric with reactive disperse dye contain acyl fluoride group in supercritical carbon dioxide. Dyes Pigments 139:566–574. https://doi.org/10.1016/j.dyepig.2016.12.050

Yin C, Li J, Xu Q, Peng Q, Liu Y, Shen X (2007) Chemical modification of cotton cellulose in supercritical carbon dioxide: synthesis and characterization of cellulose carbamate. Carbohyd Polym 67:147–154. https://doi.org/10.1016/j.carbpol.2006.05.010

Yue Y, Han G, Wu Q (2013) Transitional properties of cotton fibers from cellulose i to cellulose II structure. BioRes 8:6460–6471. https://doi.org/10.15376/biores.8.4.6460-6471

Funding

This work was financially supported by the China National Textile & Apparel Council (2013 “Textile Vision” Applied Basic Research, 2013–153).

Author information

Authors and Affiliations

Contributions

Conceptualization: Yonghong Liang, Wenju Zhu, Cong Zhang, Yingjie Cai; Methodology: Yonghong Liang, Wenju Zhu, Cong Zhang, Md Shipan Mia, Md. Nahid Pervez, Rahul Navik; Formal analysis and investigation: Yonghong Liang, Wenju Zhu, Cong Zhang, Md Shipan Mia, Md. Nahid Pervez, Rahul Navik, Xiao Ding, Md. Ibrahim H. Mondal, Yingjie Cai; Writing—original draft preparation: Yonghong Liang, Wenju Zhu, Cong Zhang, Md Shipan Mia, Md. Nahid Pervez, Rahul Navik; Writing—review and editing: Yingjie Cai, Lina Lin; Funding acquisition: Yingjie Cai; Supervision: Yingjie Cai, Lina Lin.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that they are relevant to the content of this article.

Human and animal rights

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liang, Y., Zhu, W., Zhang, C. et al. Post-treatment of reactive dyed cotton fabrics by caustic mercerization and liquid ammonia treatment. Cellulose 28, 7435–7453 (2021). https://doi.org/10.1007/s10570-021-03984-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03984-7