Abstract

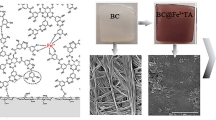

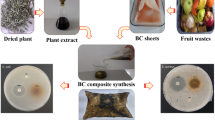

The present investigation reports, the bacterial cellulose (BC) a high-purity polymer produced from isolated strain ZKE7. BC production was optimized by Plackett–Burman and central composite designs yielding 18.5 g/l BC with a 4.5-fold enhancement. BC composites functionalized with antibiotics, BC-gelatin hydrogel, BC-Chitosan hydrogel and BC silver nanoparticle composites were developed and evaluated for water retention capability, moisture content and protein adsorption. The drug release behavior of the composites was consistent for controlled drug delivery. Composites were assessed for functional characteristic such as antimicrobial properties. BC composites functionalized with Neotericine exhibited antifungal activity against Candida albicans. Other composites showed pronounced antibacterial properties against Escherichia coli, Bacillus subtilis and Micrococcus luteus. Structural and thermal characterization of BC composites was carried out by FTIR, SEM with energy dispersive X-ray analysis, TGA and differential scanning calorimetry analysis. The results reveal high BC production with excellent properties that can be employed in biomedical field.

Similar content being viewed by others

References

Abdelraof M, Hasanin MS, El-Saied H (2019) Ecofriendly green conversion of potato peel wastes to high productivity bacterial cellulose. Carbohydr Polym 211:75–83. https://doi.org/10.1016/j.carbpol.2019.01.095

An SJ, Lee SH, Huh JB, Jeong SI, Park JS, Gwon HJ, Kang ES, Jeong CM, Lim YM (2017) Preparation and characterization of resorbable bacterial cellulose membranes treated by electron beam irradiation for guided bone regeneration. Int J Mol Sci 18:2236

Aytekin AÖ, Demirbağ DD, Bayrakdar T (2016) The statistical optimization of bacterial cellulose production via semi-continuous operation mode. J Ind Eng Chem 37:243–250

Azeredo HMC, Barud H, Farinas CS, Vasconcellos VM, Claro AM (2019) Bacterial cellulose as a raw material for food and food packaging applications. Front Sustain Food Syst 3:7

Bagewadi ZK, Mulla SI, Ninnekar HZ (2016a) Purification and characterization of endo β-1,4-d-glucanase From Trichoderma harzianum strain HZN11 and its application in production of bioethanol from sweet sorghum bagasse. 3 Biotech 6:101

Bagewadi ZK, Mulla SI, Shouche Y, Ninnekar HZ (2016b) Xylanase production from Penicillium citrinum isolate HZN13 using response surface methodology and characterization of immobilized xylanase on glutaraldehyde-activated calcium–alginate beads. 3 Biotech 6:164

Bagewadi ZK, Mulla SI, Ninnekar HZ (2017) Optimization of laccase production and its application in delignification of biomass. Int J Recycl Org Waste Agric 6:351–365

Bagewadi ZK, Mulla SI, Ninnekar HZ (2018) Response surface methodology based optimization of keratinase production from Trichoderma harzianum isolate HZN12 using chicken feather waste and its application in dehairing of hide. J Environ Chem Eng 6:4828–4839

Bagewadi ZK, Bhavikatti JS, Muddapur UM, Yaraguppi DA, Mulla SI (2020) Statistical optimization and characterization of bacterial cellulose produced by isolated thermophilic Bacillus licheniformis strain ZBT2. Carbohydr Res 491:107979. https://doi.org/10.1016/j.carres.2020.107979

Basu A, Vadanan SV, Lim S (2019) Rational design of a scalable bioprocess platform for bacterial cellulose production. Carbohydr Polym 207:684–693. https://doi.org/10.1016/j.carbpol.2018.10.085

Buldum G, Bismarck A, Mantalaris A (2018) Recombinant biosynthesis of bacterial cellulose in genetically modified Escherichia coli. Bioproc Biosyst Eng 41(2):265–279. https://doi.org/10.1007/s00449-017-1864-1

Castro C, Zuluaga R, Alvarez C, Putaux JL, Caro G, Rojas OJ, Mondragon I, Ganan P (2012) Bacterial cellulose produced by a new acid-resistant strain of Gluconacetobacter genus. Carbohydr Polym 89(4):1033–1037. https://doi.org/10.1016/j.carbpol.2012.03.045

Dayal MS, Goswami N, Sahai A, Jain V, Mathur G, Mathur A (2013) Effect of media components on cell growth and bacterial cellulose production from Acetobacter aceti MTCC 2623. Carbohydr Polym 94(1):12–16. https://doi.org/10.1016/j.carbpol.2013.01.018

Dorame-Miranda RF, Gamez-Meza N, Medina-Juarez LA, Ezquerra-Brauer JM, Ovando-Martínez M, Lizardi-Mendoza J (2019) Bacterial cellulose production by Gluconacetobacter entanii using pecan nutshell as carbon source and its chemical functionalization. Carbohydr Polym 207:91–99

Du R, Wang Y, Zhao F, Qiao X, Song Q, Li S, Kim RC, Pan L, Han Y, Xiao H, Zhou Z (2018) Production, optimization and partial characterization of bacterial cellulose from Gluconacetobacter xylinus TJU-D2. Waste Biomass Valori 11:1681–1690. https://doi.org/10.1007/s12649-018-0440-5

Gayathri G, Srinikethan G (2018) Crude glycerol as a cost-effective carbon source for the production of cellulose by K. saccharivorans. Biocatal Agric Biotechnol 16:326–330

Gayathri G, Srinikethan G (2019) Bacterial Cellulose production by K. saccharivorans BC1 strain using crude distillery effluent as cheap and cost effective nutrient medium. Int J Biol Macromol 138:950–957

Gupta A, Keddie DJ, Kannappan V, Gibson H, Khalil IR, Kowalczuk M, Martin C, Shuai X, Radecka I (2019a) Production and characterisation of bacterial cellulose hydrogels loaded with curcumin encapsulated in cyclodextrins as wound dressings. Eur Polym J 118:437–450

Gupta A, Kowalczuk M, Heaselgrave W, Britland ST, Martin C, Radecka I (2019b) The production and application of hydrogels for wound management: a review. Eur Polym J 111:134–151

Han YH, Mao HL, Wang SS, Deng JC, Chen DL, Li M (2020) Ecofriendly green biosynthesis of bacterial cellulose by Komagataeibacter xylinus B2-1 using the shell extract of Sapindus mukorossi Gaertn. as culture medium. Cellulose 27:1255–1272

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum. II. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58(2):345–352. https://doi.org/10.1042/bj0580345

Isfahani FM, Tahmourespour A, Hoodaji M, Ataabadi M, Mohammadi A (2018) Characterizing the new bacterial isolates of high yielding exopolysaccharides under hypersaline conditions. J Clean Prod 185:922–928

Jahan F, Kumar V, Saxena RK (2018) Distillery effluent as a potential medium for bacterial cellulose production: a biopolymer of great commercial importance. Bioresour Technol 250:922–926

Kim SS, Lee SY, Park KJ, Park SM, An HJ, Hyun JM, Choi YH (2017) Gluconacetobacter sp. gel_SEA623-2, bacterial cellulose producing bacterium isolated from citrus fruit juice. Saudi J Biol Sci 24(2):314–319. https://doi.org/10.1016/j.sjbs.2015.09.031

Kumar V, Sharma DK, Bansal V, Mehta D, Sangwan RS, Yadav SK (2019) Efficient and economic process for the production of bacterial cellulose from isolated strain of Acetobacter pasteurianus of RSV-4 bacterium. Bioresour Technol 275:430–433. https://doi.org/10.1016/j.biortech.2018.12.042

Lin SP, Huang YH, Hsu KD, Lai YJ, Chen YK, Cheng KC (2016) Isolation and identification of cellulose-producing strain Komagataeibacter intermedius from fermented fruit juice. Carbohydr Polym 151:827–833. https://doi.org/10.1016/j.carbpol.2016.06.032

Liu D, Cao Y, Qu R, Gao G, Chen S, Zhang Y, Wu M, Ma T, Li G (2019) Production of bacterial cellulose hydrogels with tailored crystallinity from Enterobacter sp. FY-07 by the controlled expression of colanic acid synthetic genes. Carbohydr Polym 207:563–570. https://doi.org/10.1016/j.carbpol.2018.12.014

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193(1):265–275

Lu T, Gao H, Liao B, Wu J, Zhang W, Huang J, Liu M, Huang J, Chang Z, Jin M, Yi Z, Jiang D (2020) Characterization and optimization of production of bacterial cellulose from strain CGMCC 17276 based on whole-genome analysis. Carbohydr Polym 232:115788. https://doi.org/10.1016/j.carbpol.2019.115788

Machado RTA, Meneguin AB, Sábio RM, Franco DF, Antonio SG, Gutierrez J, Tercjak A, Berretta AA, Ribeiro SJL, Lazarini SC, Lustri WR, Barud HS (2018) Komagataeibacter rhaeticus grown in sugarcane molasses-supplemented culture medium as a strategy for enhancing bacterial cellulose production. Ind Crop Prod 122:637–646

Mohamed SS, Amer SK, Selim MS, Rifaat HM (2018) Characterization and applications of exopolysaccharide produced by 5 marine Bacillus altitudinis MSH2014 from Ras Mohamed, Sinai, Egypt. Egypt J Basic Appl Sci 5:204–209

Mulla SI, Sun Q, Hu A, Wang Y, Ashfaq M, Eqani SA, Yu CP (2016a) Evaluation of sulfadiazine degradation in three newly isolated pure bacterial cultures. PLoS ONE 11(10):e0165013. https://doi.org/10.1371/journal.pone.0165013

Mulla SI, Wang H, Sun Q, Hu A, Yu CP (2016b) Characterization of triclosan metabolism in Sphingomonas sp. strain YL-JM2C. Sci Rep 6:21965. https://doi.org/10.1038/srep21965

Mulla SI, Hu A, Sun Q, Li J, Suanon F, Ashfaq M, Yu CP (2018) Biodegradation of sulfamethoxazole in bacteria from three different origins. J Environ Manag 206:93–102. https://doi.org/10.1016/j.jenvman.2017.10.029

Numata Y, Kono H, Mori A, Kishimoto R, Tajima K (2019) Structural and rheological characterization of bacterial cellulose gels obtained from Gluconacetobacter genus. Food Hydrocoll 92:233–239

Pandey M, Amin MCIM, Ahmad N, Abeer MM (2013) Rapid synthesis of superabsorbent smart-swelling bacterial cellulose/acrylamide-based hydrogels for drug delivery. Int J Polym Sci. https://doi.org/10.1155/2013/905471

Parte FGB, Santoso SP, Chou CC, Verma V, Wang HT, Ismadji S, Cheng KC (2020) Current progress on the production, modification, and applications of bacterial cellulose. Crit Rev Biotechnol 40:397–414. https://doi.org/10.1080/07388551.2020.1713721

Pavaloiu RD, Stoica-Guzun A, Stroescu M, Jinga SI, Dobre T (2014) Composite films of poly(vinyl alcohol)–chitosan–bacterial cellulose for drug controlled release. Int J Biol Macromol 68:117–124

Qiao N, Fan X, Zhang X, Shi Y, Wang L, Yu D (2019) Soybean oil refinery effluent treatment and its utilization for bacterial cellulose production by Gluconacetobacter xylinus. Food Hydrocolloids 97:105185

Raiszadeh-Jahromi Y, Rezazadeh-Bari M, Almasi H, Amiri S (2020) Optimization of bacterial cellulose production by Komagataeibacter xylinus PTCC 1734 in a low-cost medium using optimal combined design. J Food Sci Technol 57(7):2524–2533. https://doi.org/10.1007/s13197-020-04289-6

Salari M, Khiabani MS, Mokarram RR, Ghanbarzadeh B, Kafil HS (2019) Development and evaluation of chitosan based active nanocomposite films containing bacterial cellulose nanocrystals and silver nanoparticles. Food Hydrocoll 84:414–423

Shao W, Liu H, Wang S, Wu J, Huang M, Min H, Liu X (2016) Controlled release and antibacterial activity of tetracycline hydrochloride-loaded bacterial cellulose composite membranes. Carbohydr Polym 145:114–120. https://doi.org/10.1016/j.carbpol.2016.02.065

Singh O, Panesar PS, Chopra HK (2017) Response surface optimization for cellulose production from agro industrial waste by using new bacterial isolate Gluconacetobacter xylinus C18. Food Sci Biotechnol 26:1019–1028

Soemphol W, Hongsachart P, Tanamool V (2018) Production and characterization of bacterial cellulose produced from agricultural by-product by Gluconacetobacter strains. Mater Today Proc 5:11159–11168

Treesuppharat W, Rojanapanthu P, Siangsanoh C, Manuspiya H, Ummartyotin S (2017) Synthesis and characterization of bacterial cellulose and gelatin-based hydrogel composites for drug-delivery systems. Biotechnol Rep 15:84–91. https://doi.org/10.1016/j.btre.2017.07.002

Volova TG, Shumilova AA, Shidlovskiy IP, Nikolaeva ED, Sukovatiy AG, Vasiliev AD, Shishatskaya EI (2018a) Antibacterial properties of films of cellulose composites with silver nanoparticles and antibiotics. Polym Test 65:54–68

Volova TG, Prudnikova SV, Sukovatyi AG, Shishatskaya EI (2018b) Production andproperties of bacterial cellulose by the strain Komagataeibacter xylinus B-12068. Appl Microbiol Biot 102:7417–7428. https://doi.org/10.1007/s00253-018-9198-8

Wahid F, Hu XH, Chu LQ, Jia SR, Xie YY, Zhong C (2019) Development of bacterial cellulose/chitosan based semi-interpenetrating hydrogels with improved mechanical and antibacterial properties. Int J Biol Macromol 122:380–387. https://doi.org/10.1016/j.ijbiomac.2018.10.105

Wu M, Chen W, Hu J, Tian D, Shen F, Zeng Y, Yang G, Zhang Y, Deng S (2019) Valorizing kitchen waste through bacterial cellulose production towards a more sustainable biorefiner. Sci Total Environ 695:133898

Yang HJ, Lee T, Kim JR, Choi YE, Park C (2019) Improved production of bacterial cellulose from waste glycerol through investigation of inhibitory effects of crude glycerol-derived compounds by Gluconacetobacter xylinus. J Ind Eng Chem 75:158–163

Ye J, Zheng S, Zhang Z, Yang F, Ma K, Feng Y, Zheng J, Mao D, Yang X (2019) Bacterial cellulose production by Acetobacter xylinum ATCC 23767 using tobacco waste extract as culture medium. Bioresour Technol 274:518–524

Zeng X, Small DP, Wan W (2011) Statistical optimization of culture conditions for bacterial cellulose production by Acetobacter xylinum BPR 2001 from maple syrup. Carbohydr Polym 85:506–513

Zywicka A, Junka AF, Szymczyk P, Chodaczek G, Grzesiak J, Sedghizadeh PP, Fijalkowski K (2018) Bacterial cellulose yield increased over 500% by supplementation of medium with vegetable oil. Carbohydr Polym 199:294–303. https://doi.org/10.1016/j.carbpol.2018.06.126

Acknowledgments

The first author who is the corresponding author thank KLE Technological University, Hubballi for providing funding to carry out the present research work through Research Group (RG) projects.

Author information

Authors and Affiliations

Contributions

ZB and VD have designed the experimental work, executed all the experiments and carried out all the data analysis. ZB, VD, SIM, SD, UM, DY, VDR, JB and SM were involved in interpretation of data. ZB and VD have written the manuscript. All the authors have approved the contents of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

All the authors affirm that they have no argument of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bagewadi, Z.K., Dsouza, V., Mulla, S.I. et al. Structural and functional characterization of bacterial cellulose from Enterobacter hormaechei subsp. steigerwaltii strain ZKE7. Cellulose 27, 9181–9199 (2020). https://doi.org/10.1007/s10570-020-03412-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03412-2