Abstract

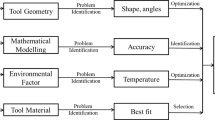

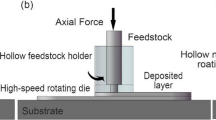

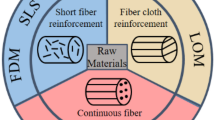

Cellulose fibers, such as cotton and linen, are abundant in farmer’s fields. The traditional bottom-up technology to process these short staple fibers is spinning. State-of-the-art spinning technology requires not only high throughput processing of the cellulose fibers, but also the addition of functionalities and value into the supply chain. Recently, a modified ring spinning system has been developed which introduces a false twist into a traditional ring spinning frame. The modified system produces cellulose yarns that have a high strength but low twist, and a soft hand similar to cashmere. Unlike traditional textile finishing treatments which consume plenty of chemicals, water, and energy, this method is purely physical and sustainable. The superior properties of the modified cellulose yarns are attributed to the modified yarn morphology and structure. Theoretical investigation is, therefore, important in understanding of the spinning mechanisms of the modified ring spinning process that changes the morphology and structure of the cellulose yarns. In this paper, yarn behavior constrained to lie on a moving solid cylinder was theoretically and experimentally investigated. Equations of motion were derived based on the Cosserat theory and numerical solutions in steady-state were obtained in terms of yarn spatial path, yarn tension, twist distribution, yarn bending, and torsional moments. Effects of various spinning parameters including wrap angle, speed of the moving cylinder, yarn diameter, yarn tension, yarn twist, and frictional coefficient, on yarn behavior were discussed. The results suggested that in most cases the bending and torsional moments are of the same order of magnitude, and thus the effect of bending cannot be neglected. Experiments in the modified ring spinning system were conducted to verify the theoretical work, and good agreement has been made. Some simulation results of this study were compared with the results of earlier models as well as with experimental data, and it was found that the current model can obtain a more accurate prediction than previous models in terms of yarn twist and tension. The results gained from this study will enrich our understanding of the spinning mechanism of the modified ring spinning process and better handle of cellulose fibers for functional and value-added applications.

Similar content being viewed by others

References

Bennett JM, Postle R (1979) A study of yarn torque and its dependence on the distribution of fiber tensile stress in the yarn part II: experimental. J Text Inst 70:133–141

César NR, Pereira-da-Silva MA, Botaro VR, de Menezes AJ (2015) Cellulose nanocrystals from natural fiber of the macrophyte Typha domingensis: extraction and characterization. Cellulose 22:449–460

Feng J, Xu BG, Tao XM (2012) Dynamic measurement and modelling of flexible yarn dynamic behaviour on a moving cylindrical solid structure. Meas Sci Technol 23(11):115605

Fraser W (1993) On the theory of ring spinning. Proc R Soc Lond Ser A Math 342:439–468

Fraser W, Stump D (1998) The equilibrium of the convergence point in two-strand yarn plying. Int J Solids Struct 35:285–298

Grosberg P, Oxenham W, Miao M (1987) The insertion of ‘Twist’into yarns by means of air-jets. Part II: twist distribution and twist-insertion rates in air-jet twisting. J Text Inst 78:204–219

Guo BP, Tao XM, Lo TY (2000) A mechanical model of yarn twist blockage in rotor spinning. Text Res J 70:11–17

Guo Y, Feng J, Yin R, Wang XG, van der Sluijs M, Tao XM (2015) Investigation and evaluation on fine Upland cotton blend yarns made by the modified ring spinning system. Text Res J 85:1355–1366

Hearle JWS, Grosberg P, Backer S (1969) Structural mechanics of fibers, yarns, and fabrics. Wiley, New York

Hua T, Tao XM, Cheng KPS, Xu BG, Huang XX (2013) An experimental study of improving fabric appearance of denim by using low torque singles ring spun yarns. Text Res J 83:1371–1385

Kim T-K, Son Y-A (2005) Effect of reactive anionic agent on dyeing of cellulosic fibers with a Berberine colorant—part 2: anionic agent treatment and antimicrobial activity of a Berberine dyeing. Dyes Pigments 64:85–89

Lawrence CA (2010) Advances in yarn spinning technology. Woodhead Publishing Ltd, Cambridge

Liu X-H, Zhang Q-Y, Cheng B-W, Ren Y-L, Zhang Y-G, Ding C (2018) Durable flame retardant cellulosic fibers modified with novel, facile and efficient phytic acid-based finishing agent. Cellulose 25:799–811

Liu Y, Xie J, Wu N, Ma Y, Menon C, Tong J (2019) Characterization of natural cellulose fiber from corn stalk waste subjected to different surface treatments. Cellulose 26:4707–4719

Love AEH (1927) A treatise on the mathematical theory of elasticity. Cambridge University Press, Cambridge

Miao M, Chen R (1993) Yarn twisting dynamics. Text Res J 63:150–158

Morán JI, Alvarez VA, Cyras VP, Vázquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15:149–159

Stump DM, Fraser WB (1996) Transient solutions of the ring-spinning balloon equations. J Appl Mech-T ASME 63:523–528

Tandon S, Kim S, Choi F (1995) The torsional behaviour of singles yarns. Part II: evaluation. J Text Inst 86:200–217

Tang H, Xu B, Tao X, Feng J (2011) Mathematical modeling and numerical simulation of yarn behavior in a modified ring spinning system. Appl Math Model 35:139–151

Tao XM, Yin R (2019) Apparatus and method for imparting false twist to a yarn. U.S. Patent application no. 15/801,099

van der Heijden GHM, Thompson JMT (2000) Helical and localised buckling in twisted rods: a unified analysis of the symmetric case. Nonlinear Dyn 21:71–99

van der Heijden GHM, Champneys AR, Thompson JMT (2002) Spatially complex localisation in twisted elastic rods constrained to a cylinder. Int J Solids Struct 39:1863–1883

Xu BG, Tao XM (2003) Integrated approach to dynamic analysis of yarn twist distribution in rotor spinning. Text Res J 73:79–89

Yang K, Tao XM, Xu BG, Lam J (2007) Structure and properties of low twist short-staple singles ring spun yarns. Text Res J 77:675–685

Yin R, Gu H-b (2011a) Numerical simulation of quasi-stationary ring spinning process linear elastic yarn. Text Res J 81:22–27

Yin R, Gu H (2011b) Accurate prediction of the ring-spinning equation in zero air drag based on homotopy perturbation method. J Text Inst 102:763–766

Yin R, Liu Y, Gu H (2010) Artificial parameter perturbation method and parameter-expansion method used in accurate prediction of the ring-spinning balloon in zero air drag. In: 2010 international conference on system science, engineering design and manufacturing informatization, IEEE, pp 222–225

Yin R, Tao X, Xu B (2016) Mathematical modeling of yarn dynamics in a generalized twisting system. Sci Rep-Uk 6:24432

Yin R, Tao X, Xu B (2018) Variation of false twist on spinning process stability and resultant yarn properties in a modified ring spinning frame. Text Res J 88:1876–1892

Yin R, Tao X-M, Xu B-g (2020a) Systematic investigation of twist generation and propagation in a modified ring spinning system. Text Res J 90:367–375

Yin R, Tao X-M, Xu B-g (2020b) Yarn and fabric properties in a modified ring spinning system considering the effect of the friction surface of the false-twister. Text Res J 90:572–580

Acknowledgments

This research was funded in part through a research grant from the Innovation and Technology Commission of the Hong Kong Special Administrative Region, China (Project No: ITP/021/17TI) and a postgraduate scholarship by the Hong Kong Polytechnic University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yin, R., Tao, X. & Jasper, W. A theoretical model to investigate the performance of cellulose yarns constrained to lie on a moving solid cylinder. Cellulose 27, 9683–9698 (2020). https://doi.org/10.1007/s10570-020-03408-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03408-y