Abstract

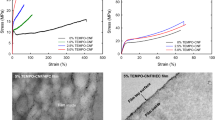

The brittleness of ethyl cellulose (EC) film limited its full applications, and the addition of plasticizers is one of the most common methods to reduce its brittleness. However, the mechanical properties are normally dropped with the addition of plasticizers. Herein, cellulose nanocrystal (CNC) was chosen as a reinforcing agent to improve its mechanical properties. CNC was firstly extracted from the tobacco-stem and then modified by epoxidized soybean oil (ESO) via ring-opening grafting to obtain epoxidized soybean oil grafting CNC (ECNC). The grafting effect was evaluated by FTIR and XPS. After that, the films of ECNC/EC nanocomposites were prepared by the solution-casting method, and their mechanical, thermal and optical properties and fracture morphology were investigated. The results showed that at 4 phr loading of ECNC, the tensile strength of the nanocomposite film was up to 43.7 Mpa (about twice as much as that of the EC film plasticized by ESO), and the elongation at break was not influenced. Moreover, a higher thermal decomposition temperature was achieved for the ECNC/EC films. Besides, owing to the good dispersion, ECNC had no significant impact on the transparency, and the films presented high light transmittance in the visible light region.

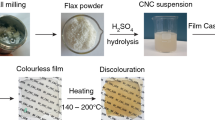

Graphic abstract

Similar content being viewed by others

References

Abraham E, Kam D, Nevo Y, Slattegard R, Rivkin A, Lapidot S, Shoseyov O (2016a) Highly modified cellulose nanocrystals and formation of epoxy-nanocrystalline cellulose (CNC) nanocomposites. ACS Appl Mater Interfaces 8:28086–28095

Abraham E, Nevo Y, Slattegard R, Attias N, Sharon S, Lapidot S, Shoseyov O (2016b) highly hydrophobic thermally stable liquid crystalline cellulosic nanomaterials. ACS Sustain Chem Eng 4:1338–1346

Arca H, Mosquera-Giraldo L, Bi V, Xu D, Taylor LS, Edgar K (2018) Pharmaceutical applications of cellulose ethers and cellulose ether esters. Biomacromolecules 19:2351–2376

Boujemaoui A, Mongkhontreerat S, Malmström E, Carlmark A (2015) Preparation and characterization of functionalized cellulose nanocrystals. Carbohydr Polym 115:457–464

Bruno L, Kasapis S, Heng PWS (2012) Effect of hydration on the structure of non aqueous ethyl cellulose/propylene glycol dicaprylate gels. Int J Biol Macromol 50:385–392

Cai J et al (2016) Well-aligned cellulose nanofiber-reinforced polyvinyl alcohol composite film: mechanical and optical properties. Carbohydr Polym 140:238–245

Chi K, Catchmark JM (2017) Enhanced dispersion and interface compatibilization of crystalline nanocellulose in polylactide by surfactant adsorption. Cellulose 24:4845–4860

Davidovich-Pinhas M, Barbut S, Marangoni AG (2014) Physical structure and thermal behavior of ethylcellulose. Cellulose 21:3243–3255

Davidovich-Pinhas M, Barbut S, Marangoni AG (2015) The gelation of oil using ethyl cellulose. Carbohydr Polym 117:869–878

de Brabander C, van den Mooter G, Vervaet C, Remon JP (2002) Characterization of ibuprofen as a nontraditional plasticizer of ethyl cellulose. J Pharm Sci 91:1678–1685

Dhar P, Kumar A, Katiyar V (2015) Fabrication of cellulose nanocrystal supported stable Fe(0) nanoparticles: a sustainable catalyst for dye reduction, organic conversion and chemo–magnetic propulsion. Cellulose 22:3755–3771

Djerafi R, Masmoudi Y, Crampon C, Meniai A, Badens E (2015) Supercritical anti-solvent precipitation of ethyl cellulose. J Supercrit Fluids 105:92–98

Duan B, Huang Y, Lu A, Zhang L (2018) Recent advances in chitin based materials constructed via physical methods. Prog Polym Sci 82:1–33

Eichhorn SJ et al (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

El Achaby M, El Miri N, Hannache H, Gmouh S, Trabadelo V, Aboulkas A, Ben Youcef H (2018) Cellulose nanocrystals from Miscanthus fibers: insights into rheological, physico-chemical properties and polymer reinforcing ability. Cellulose 25:6603–6619

Gagandeep GT, Malik B, Rath G, Goyal AK (2014) Development and characterization of nano-fiber patch for the treatment of glaucoma. Eur J Pharm Sci 53:10–16

Gan L, Liao J, Lin N, Hu C, Wang H, Huang J (2017) Focus on gradientwise control of the surface acetylation of cellulose nanocrystals to optimize mechanical reinforcement for hydrophobic polyester-based nanocomposites. ACS Omega 2:4725–4736

Gao T, Li Y-Y, Bao R-Y, Liu Z-Y, Xie B-H, Yang M-B, Yang W (2017) Tailoring co-continuous like morphology in blends with highly asymmetric composition by MWCNTs: towards biodegradable high-performance electrical conductive poly(l-lactide)/poly(3-hydroxybutyrate-co-4-hydroxybutyrate) blends. Compos Sci Technol 152:111–119

Garcia-Valdez O, Champagne P, Cunningham MF (2018) Graft modification of natural polysaccharides via reversible deactivation radical polymerization. Prog Polym Sci 76:151–173

Iqbal H, Kyazze G, Tron T, Keshavarz T (2014) “One-pot” synthesis and characterisation of novel P (3HB)–ethyl cellulose based graft composites through lipase catalysed esterification. Polym Chem 5:7004–7012

Kang H, Liu W, He B, Shen D, Ma L, Huang Y (2006) Synthesis of amphiphilic ethyl cellulose grafting poly (acrylic acid) copolymers and their self-assembly morphologies in water. Polymer 47:7927–7934

Kang H, Liu R, Yong H (2013) Cellulose derivatives and graft copolymers as blocks for functional materials. Polym Int 62:338–344

Kargarzadeh H et al (2018) Recent developments in nanocellulose-based biodegradable polymers, thermoplastic polymers, and porous nanocomposites. Prog Polym Sci 87:197–227

Kasiri N, Fathi M (2018) Entrapment of peppermint oil using cellulose nanocrystals. Cellulose 25:319–329

Khanjanzadeh H, Behrooz R, Bahramifar N, Gindl-Altmutter W, Bacher M, Edler M, Griesser T (2018) Surface chemical functionalization of cellulose nanocrystals by 3-aminopropyltriethoxysilane. Int J Biol Macromol 106:1288–1296

Lee A, Choi S-S, Song SJ, Baek KY, Hwang S (2014) Cationically photopolymerizable epoxy-functionalized thermoplastic polysilsesquioxanes: synthesis and properties. RSC Adv 4:56532–56538

Li X, Jiang F, Ni X, Yan W, Fang Y, Corke H, Xiao M (2015) Preparation and characterization of konjac glucomannan and ethyl cellulose blend films. Food Hydrocoll 44:229–236

Ling Z et al (2019) Effects of ball milling on the structure of cotton cellulose. Cellulose 26:305–328

Liu W et al (2019a) Preparation and characterization of reinforced starch-based composites with compatibilizer by simple extrusion. Carbohydr Polym 223:115122

Liu W et al (2019b) Effects of graft architecture on cellulose-based ordered porous film prepared by breath figures. Cellulose 26:6201–6213

Liu W et al (2020) Tailoring ordered microporous structure of cellulose-based membranes through molecular hydrophobicity design. Carbohydr Polym 229:115425

Mathew AP, Oksman K, Karim Z, Liu P, Khan SA, Naseri N (2014) Process scale up and characterization of wood cellulose nanocrystals hydrolysed using bioethanol pilot plant. Ind Crops Prod 58:212–219

Mohamed MA et al (2017) Physicochemical characterization of cellulose nanocrystal and nanoporous self-assembled CNC membrane derived from Ceiba pentandra. Carbohydr Polym 157:1892–1902

Olejar KJ, Ray S, Ricci A, Kilmartin PA (2014) Superior antioxidant polymer films created through the incorporation of grape tannins in ethyl cellulose. Cellulose 21:4545–4556

Orasugh JT et al (2018a) Jute cellulose nano-fibrils/hydroxypropylmethylcellulose nanocomposite: a novel material with potential for application in packaging and transdermal drug delivery system. Ind Crops Prod 112:633–643

Orasugh JT et al (2018b) Synthesis of methylcellulose/cellulose nano-crystals nanocomposites: material properties and study of sustained release of ketorolac tromethamine. Carbohydr Polym 188:168–180

Pajkert R, Kolomeitsev AA, Milewska M, Röschenthaler G-V, Koroniak H (2008) TiCl4 and Grignard reagent-promoted ring-opening reactions of various epoxides: synthesis of γ-hydroxy-α, α-difluoromethylenephosphonates. Tetrahedron Lett 49:6046–6049

Qian S, Zhang H, Yao W, Sheng K (2018) Effects of bamboo cellulose nanowhisker content on the morphology, crystallization, mechanical, and thermal properties of PLA matrix biocomposites. Compos Part B Eng 133:203–209

Raquez JM, Murena Y, Goffin AL, Habibi Y, Ruelle B, DeBuyl F, Dubois P (2012) Surface-modification of cellulose nanowhiskers and their use as nanoreinforcers into polylactide: a sustainably-integrated approach. Compos Sci Technol 72:544–549

Segal L, Creely J, Martin AEJ, Conrad C (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Spinella S et al (2015) Polylactide/cellulose nanocrystal nanocomposites: efficient routes for nanofiber modification and effects of nanofiber chemistry on PLA reinforcement. Polymer 65:9–17

Sun Q, Li G, Dai L, Ji N, Xiong L (2014) Green preparation and characterisation of waxy maize starch nanoparticles through enzymolysis and recrystallisation. Food Chem 162:223–228

Tarvainen M et al (2003) Enhanced film-forming properties for ethyl cellulose and starch acetate using n-alkenyl succinic anhydrides as novel plasticizers. Eur J Pharm Sci 19:363–371

Volkova GI, Anufriev RV, Yudina NV (2016) Effect of ultrasonic treatment on the composition and properties of waxy high-resin oil. Pet Chem 56:683–689

Wang S, Lu A, Zhang L (2016) Recent advances in regenerated cellulose materials. Prog Polym Sci 53:169–206

Wu K, Zhu Q, Qian H, Xiao M, Corke H, Nishinari K, Jiang F (2018) Controllable hydrophilicity–hydrophobicity and related properties of konjac glucomannan and ethyl cellulose composite films. Food Hydrocoll 79:301–309

Yang D et al (2014) “Green” films from renewable resources: properties of epoxidized soybean oil plasticized ethyl cellulose films. Carbohydr Polym 103:198–206

Yang Y, Wang H, Li H, Zhimin O, Yang GS (2018) 3D printed tablets with internal scaffold structure using ethyl cellulose to achieve sustained ibuprofen release. Eur J Pharm Sci 115:11–18

Yin Y, Tian X, Jiang X, Wang H, Gao W (2016) Modification of cellulose nanocrystal via SI-ATRP of styrene and the mechanism of its reinforcement of polymethylmethacrylate. Carbohydr Polym 142:206–212

Yuan B, Sun H, Wang T, Xu Y, Li P, Kong Y, Niu QJ (2016) Propylene/propane permeation properties of ethyl cellulose (EC) mixed matrix membranes fabricated by incorporation of nanoporous graphene nanosheets. Scientific Reports 6:28509

Yue L et al (2018) Surface-modified cellulose nanocrystals for biobased epoxy nanocomposites. Polymer 134:155–162

Zhu J, Dong X-T, Wang X-L, Wang Y-Z (2010) Preparation and properties of a novel biodegradable ethyl cellulose grafting copolymer with poly (p-dioxanone) side-chains. Carbohydr Polym 80:350–359

Acknowledgments

The work was supported by Natural Science Foundation of Hunan Province of China (No. 2018JJ2088), Scientific Research Foundation of Hunan Provincial Education Department of China (No. 15K034) and Postgraduate Research and Innovation Project of Hunan Province of China (Nos. CX20190839 and CX2018B735).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shi, J., Liu, W., Jiang, X. et al. Preparation of cellulose nanocrystal from tobacco-stem and its application in ethyl cellulose film as a reinforcing agent. Cellulose 27, 1393–1406 (2020). https://doi.org/10.1007/s10570-019-02904-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02904-0