Abstract

There is an increasing attention to cellulose nanofibrils (CNFs) for food packaging applications due to their abundance, biodegradability, and low gas permeability. In this work, oxygen and water barrier performance is studied for bio-nanocomposite films formed by incorporation of two types of bentonite (PGN and PGV) at different loads (15, 30 and 45 wt%) into continuous CNF matrix. The resulting hybrid films were analyzed for their morphology, surface energy, mechanical strengths as well as water/oxygen barrier qualities. Both types of bentonite lowered the CNF degradation temperature and strength to some degree for reasons not so clear but perhaps due to partial disruption of the CNF H-bond network. It was revealed from microscopic study that clay particles form a layer within cellulose chains, resulting in alteration of composite structure. The contact angle analysis by polar and nonpolar liquids, suggested the PGN-containing samples were more hydrophilic; clay induced polar functionalities to the composite. While 15% PGN load reduced the water vapor transmission rate from 425 to 375 g/m2 day, higher proportions of bentonite negatively affected this trend. Also, analysis of oxygen transmission rate showed the PGN effectively restricted the oxygen passage in dry state and to a lower extent at higher relative humidity. In WVTR analysis, PGN showed a superior performance over PGV attributable to its crystalline structure as evident in XRD patterns. The proposed hybrid CNF-BNT films in this study can present an eco-friendly alternative in packaging materials, especially where penetration of water vapor and oxygen is to be avoided.

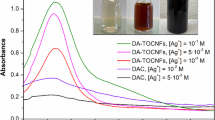

Graphical abstract

Similar content being viewed by others

Abbreviations

- CNFs:

-

Cellulose nanofibrils

- DCC:

-

Dicarboxylic acid cellulose nanofibers

- TGA:

-

Thermogravimetric analysis

- SEM:

-

Scanning electron microscope

- AFM:

-

Atomic force microscope

- WVTR:

-

Water vapor transmission rate

- WVP:

-

Water vapor permeability

- OTR:

-

Oxygen transmission rate

References

Algar I, Garcia-Astrain C, Gonzalez A et al (2016) Improved permeability properties for bacterial cellulose/montmorillonite hybrid bionanocomposite membranes by in-situ assembling. J Renew Mater 4:57–65. https://doi.org/10.7569/JRM.2015.634124

ASTM D3985–17 (2017) Standard test method for oxygen gas transmission rate through plastic film and sheeting using a coulometric sensor. ASTM International, West Conshohocken

ASTM E96, E96M–16 (2016) Standard test methods for water vapor transmission of materials. STM International, West Conshohocken

Aulin C, Gällstedt M, Lindström T (2010) Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 17:559–574

Aulin C, Salazar-Alvarez G, Lindström T (2012) High strength, flexible and transparent nanofibrillated cellulose–nanoclay biohybrid films with tunable oxygen and water vapor permeability. Nanoscale 4:6622–6628

Bedane AH, Eić M, Farmahini-Farahani M, Xiao H (2015) Water vapor transport properties of regenerated cellulose and nanofibrillated cellulose films. J Memb Sci 493:46–57

Buschle-Diller G, Zeronian SH (1992) Enhancing the reactivity and strength of cotton fibers. J Appl Polym Sci 45:967–979. https://doi.org/10.1002/app.1992.070450604

Dufresne A (2012) Nanocellulose: from nature to high performance tailored materials. Walter de Gruyter GmbH & Co KG, Berlin

Eichhorn S, Dufresne A, Aranguren M et al (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Fukuzumi H, Saito T, Iwata T et al (2009) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 10:162–165. https://doi.org/10.1021/bm801065u

Gabr MH, Phong NT, Abdelkareem MA et al (2013) Mechanical, thermal, and moisture absorption properties of nano-clay reinforced nano-cellulose biocomposites. Cellulose 20:819–826

Gamelas JAF, Ferraz E (2015) Composite films based on nanocellulose and nanoclay minerals as high strength materials with gas barrier capabilities: key points and challenges. BioResources 10:6310–6313. https://doi.org/10.15376/biores.10.4.6310-6313

Garusinghe UM, Varanasi S, Raghuwanshi VS et al (2018) Nanocellulose-montmorillonite composites of low water vapour permeability. Colloids Surf A Physicochem Eng Asp 540:233–241

Gusev AA, Lusti HR (2001) Rational design of nanocomposites for barrier applications. Adv Mater 13:1641–1643

Honorato C, Kumar V, Liu J et al (2015) Transparent nanocellulose-pigment composite films. J Mater Sci 50:7343–7352

Hubbe MA, Tayeb P, Joyce M et al (2017) Rheology of nanocellulose-rich aqueous suspensions: a review. BioResources 12:9556–9661

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chemie Int Ed 44:3358–3393

Klemm D, Kramer F, Moritz S et al (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466

Kumar V, Bollström R, Yang A et al (2014) Comparison of nano- and microfibrillated cellulose films. Cellulose 21:3443–3456

Leszczyńska A, Njuguna J, Pielichowski K, Banerjee JR (2007) Polymer/montmorillonite nanocomposites with improved thermal properties: part II. Thermal stability of montmorillonite nanocomposites based on different polymeric matrixes. Thermochim Acta 454:1–22. https://doi.org/10.1016/J.TCA.2006.11.003

Liimatainen H, Ezekiel N, Sliz R et al (2013) High-strength nanocellulose-talc hybrid barrier films. ACS Appl Mater Interfaces 5:13412–13418. https://doi.org/10.1021/am4043273

Liu A, Berglund LA (2012) Clay nanopaper composites of nacre-like structure based on montmorrilonite and cellulose nanofibers—improvements due to chitosan addition. Carbohydr Polym 87:53–60. https://doi.org/10.1016/j.carbpol.2011.07.019

Liu A, Walther A, Ikkala O et al (2011) Clay nanopaper with tough cellulose nanofiber matrix for fire retardancy and gas barrier functions. Biomacromolecules 12:633–641

Moon RJ, Martini A, Nairn J et al (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Noonan C, Tajvidi M, Tayeb AH et al (2019) Structure-property relationships in hybrid cellulose nanofibrils/nafion-based ionic polymer-metal composites. Materials (Basel) 12:1269. https://doi.org/10.3390/ma12081269

Österberg M, Vartiainen J, Lucenius J et al (2013) A fast method to produce strong NFC films as a platform for barrier and functional materials. ACS Appl Mater Interfaces 5:4640–4647

Perotti GF, Barud HS, Messaddeq Y et al (2011) Bacterial cellulose–laponite clay nanocomposites. Polymer (Guildf) 52:157–163

Priolo MA, Gamboa D, Holder KM, Grunlan JC (2010) Super gas barrier of transparent polymer–clay multilayer ultrathin films. Nano Lett 10:4970–4974

Rhim J-W, Park H-M, Ha C-S (2013) Bio-nanocomposites for food packaging applications. Prog Polym Sci 38:1629–1652. https://doi.org/10.1016/J.PROGPOLYMSCI.2013.05.008

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Sehaqui H, Liu A, Zhou Q, Berglund LA (2010) Fast preparation procedure for large, flat cellulose and cellulose/inorganic nanopaper structures. Biomacromolecules 11:2195–2198

Sehaqui H, Morimune S, Nishino T, Berglund LA (2012) Stretchable and strong cellulose nanopaper structures based on polymer-coated nanofiber networks: an alternative to nonwoven porous membranes from electrospinning. Biomacromolecules 13:3661–3667

Sinha Ray S, Bousmina M (2005) Biodegradable polymers and their layered silicate nanocomposites: in greening the 21st century materials world. Prog Mater Sci 50:962–1079. https://doi.org/10.1016/J.PMATSCI.2005.05.002

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Spence KL, Venditti RA, Rojas OJ et al (2011) Water vapor barrier properties of coated and filled microfibrillated cellulose composite films. BioResources 6:4370–4388

Tayeb AH, Tajvidi M (2018) Sustainable barrier system via self-assembly of colloidal montmorillonite and cross-linking resins on nanocellulose interfaces. ACS Appl Mater Interfaces 11:1604–1615. https://doi.org/10.1021/acsami.8b16659

Tayeb AH, Latibari AJ, Tajdini A, Sepidehdam SMJ (2012) The influence of pulp refining on de-inking potential and strength properties of ink jet printed paper. BioResources 7:3837–3846

Tayeb AH, Hubbe MA, Tayeb P et al (2017) Soy proteins as a sustainable solution to strengthen recycled paper and reduce deposition of hydrophobic contaminants in papermaking: a bench and pilot-plant study. ACS Sustain Chem Eng 5:7211–7219. https://doi.org/10.1021/acssuschemeng.7b01425

Tayeb AH, Amini E, Ghasemi S, Tajvidi M (2018) Cellulose nanomaterials—binding properties and applications: a review. Molecules 23:2684. https://doi.org/10.3390/molecules23102684

Vilela SO, Soto-Oviedo MA, Albers APF, Faez R (2007) Polyaniline and mineral clay-based conductive composites. Mater Res 10:297–300. https://doi.org/10.1590/S1516-14392007000300015

Wang J, Gardner DJ, Stark NM et al (2018) Moisture and oxygen barrier properties of cellulose nanomaterial-based films. ACS Sustain Chem Eng 6:49–70

Wu CN, Saito T, Fujisawa S et al (2012) Ultrastrong and high gas-barrier nanocellulose/clay-layered composites. Biomacromolecules 13:1927–1932. https://doi.org/10.1021/bm300465d

Yermiyahu Z, Lapides I, Yariv S (2005) Thermo-XRD-analysis of montmorillonite treated with protonated Congo-red. Curve fitting. Appl Clay Sci 30:33–41. https://doi.org/10.1016/J.CLAY.2005.03.002

Yilmaz O, Cheaburu CN, Gülümser G, Vasile C (2012) On the stability and properties of the polyacrylate/Na-MMT nanocomposite obtained by seeded emulsion polymerization. Eur Polym J 48:1683–1695

Zhou Q, Xanthos M (2009) Nanosize and microsize clay effects on the kinetics of the thermal degradation of polylactides. Polym Degrad Stab 94:327–338. https://doi.org/10.1016/J.POLYMDEGRADSTAB.2008.12.009

Acknowledgments

Funding for this study was provided by NSF REU Project #1461116 through the University of Maine’s Forest Bioproducts Research Institute.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, M., Tajvidi, M., Tayeb, A.H. et al. Effects of bentonite on physical, mechanical and barrier properties of cellulose nanofibril hybrid films for packaging applications. Cellulose 26, 5363–5379 (2019). https://doi.org/10.1007/s10570-019-02473-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02473-2