Abstract

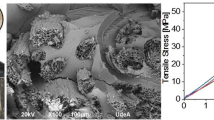

Renewable resource based hyperbranched epoxy nanocomposites have been fabricated with high tensile strength, good visual transparency, high chemical resistance and biodegradability by incorporating cellulose nanofiber (CNF) at a low dose level. The chemical structures of the nanocomposites have been confirmed by the FTIR, NMR and X-ray diffraction analyses. The morphological study by TEM analysis revealed the formation of nanofibers (diameter of ~ 40 nm and length of ~ 10 μm) and their uniform dispersion in the polymer matrix. The cured thermosets exhibited good mechanical properties like tensile strength (32 MPa), impact resistance (18.91 kJ/m), scratch hardness (> 10 kg); excellent thermal stability (245 °C), chemical resistance and biodegradability. These results have been improved with the increase of CNF percentage in the epoxy matrix. The thermosets of the nanocomposites showed visual transparency of about 82% which is almost similar to the pristine epoxy. Hence, the visual transparency, good mechanical properties (tensile strength, impact resistance etc.), chemical resistance and biodegradability of the thermoset make it suitable to be used as a sustainable material for different potential applications.

Graphical abstract

Similar content being viewed by others

References

Adcock LH, Gray CH (1956) Metabolism of sorbitol. Nature 177:329

Alemdar A, Sain M (2008) Biocomposites from wheat straw nanofibers: morphology, thermal and mechanical properties. Compos Sci Technol 68:557–565

ASTM (American Society for Testing and Materials) Volume 08.03 Plastics (III) Designation: D 5338–98 (2004) Determining aerobic biodegradation of plastic materials under controlled composting conditions. ASTM, West Conshohocken

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6:612–626

Barua S, Das G, Aidew L, Buragohain AK, Karak N (2013) Copper–copper oxide coated nanofibrillar cellulose: a promising biomaterial. RSC Adv 3:14997–15004

Bitinis N, Hernández M, Verdejo R, Kenny JM, Lopez-Manchado MA (2011) Recent advances in clay/polymer nanocomposites. Adv Mater 23:5229–5236

Chang AC, Chen S, Carter KR (2018) Cellulose nanocrystal surface modification via grafting-from sonogashira coupling of poly(ethynylene-fluorene). Cellulose 25:5731–5738

Chen C, Deng S, Yang Y, Yang D, Ye T, Li D (2018) Highly transparent chitin nanofiber/gelatin nanocomposite with enhanced mechanical properties. Cellulose 25:5063–5070

Claro P, de Campos A, Corrêa A, Rodrigues V, Luchesi B, Silva L, Tonoli G, Mattoso L, Marconcini J (2019) Curaua and eucalyptus nanofiber films by continuous casting: mixture of cellulose nanocrystals and nanofibrils. Cellulose. https://doi.org/10.1007/s10570-019-02280-9

De B, Karak N (2013) Novel high performance tough hyperbranched epoxy by an A2 + B3 polycondensation reaction. J Mater Chem A 1:348–353

De B, Gupta K, Mandal M, Karak N (2014) Biodegradable hyperbranched epoxy from castor oil-based hyperbranched polyester polyol. ACS Sustain Chem Eng 2:445–453

Duarah R, Karak N (2015) A starch based sustainable tough hyperbranched epoxy thermoset. RSC Adv 5:64456–64465

Duarah R, Singh YP, Mandal BB, Karak N (2016) Sustainable starch modified polyol based tough, biocompatible, hyperbranched polyurethane with a shape memory attribute. New J Chem 40:5152–5163

Einchhorn SJ, Dufresne A, Aranguren MM, Capadona JR, Rowan SJ, Weder C, Veigel S (2010) Review: current international research into cellulose nanofibres and composites. J Mater Sci 45:1–33

Gilmer CM, Bowden NB (2018) Reactive epoxy nanofiltration membranes with disulfide bonds for the separation of multicomponent chemical mixtures. ACS Omega 3:10216–10224

Hazarika D, Karak N (2015) Waterborne sustainable tough hyperbranched aliphatic polyester thermosets. ACS Sustain Chem Eng 3:2458–2468

Lee H, Neville K (1967) Handbook of epoxy resins. McGraw-Hill, New York

Lu Y, Larock RC (2009) Novel polymeric materials from vegetable oils and vinyl monomers: preparation, properties, and applications. Chem Sus Chem 2:136–147

Mandal A, Chakrabarty D (2011) Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydr Polym 86:1291–1299

Masoodi R, El-Hajjar RF, Pillai KM, Sabo R (2012) Mechanical characterization of cellulose nanofiber and bio-based epoxy composite. Mater Des 36:570–576

Moniruzzaman M, Winey KI (2006) Polymer nanocomposites containing carbon nanotubes. Macromolecules 39:5194–5205

Parit M, Saha P, Davis VA, Jiang Z (2018) Transparent and homogenous cellulose nanocrystal/lignin UV-protection films. ACS Omega 3:10679–10691

Rahman IA, Padavettan V (2012) Synthesis of silica nanoparticles by sol-gel: size-dependent properties, surface modification, and applications in silica-polymer nanocomposites—a review. J Nanomater 2012:8

Rong MZ, Zhang MQ, Liu Y, Yang GC, Zeng HM (2001) The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos Sci Technol 61:1437–1447

Saikia A, Karak N (2017) Renewable resource based thermostable tough hyperbranched epoxy thermosets as sustainable materials. Polym Degrad Stab 135:8–17

Samir SA, Ahmed M, Alloin F, Paillet M, Dufresne A (2004) Tangling effect in fibrillated cellulose reinforced nanocomposites. Macromolecules 37:4313–4316

Segal LGJMA, Creely JJ, Martin AE Jr, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Sen AK, Kumar S (2010) Coir-fiber-based fire retardant nano filler for epoxycomposites. J Therm Anal Calorim 101:265–271

Sestoft L (1985) An evaluation of biochemical aspects of intravenous fructose, sorbitol and xylitol administration in man. Acta Anaesthesiol Scand 29:19–29

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Soni B, Mahmoud B (2015) Chemical isolation and characterization of different cellulose nanofibers from cotton stalks. Carbohydr Polym 134:581–589

Sun XF, Xu F, Sun RC, Fowler P, Baird MS (2005) Characteristics of degraded cellulose obtained from steam-exploded wheat straw. Carbohydr Res 340:97–106

Tang L, Weder C (2010) Cellulose whisker/epoxy resin nanocomposites. ACS Appl Mater Interfaces 2:1073–1080

Van Soest JJ, Tournois H, de Wit D, Vliegenthart JF (1995) Short-range structure in (partially) crystalline potato starch determined with attenuated total reflectance Fourier-transform IR spectroscopy. Carbohydr Res 279:201–214

Xia Y, Larock RC (2010) Vegetable oil-based polymeric materials: synthesis, properties, and applications. Green Chem 12:1893–1909

Xiao B, Sun X, Sun R (2001) Chemical, structural, and thermal characterizations of alkali-soluble lignins and hemicelluloses, and cellulose from maize stems, rye straw, and rice straw. Polym Degrad Stab 74:307–319

Zhang D, Jia D (2006) Synthesis of novel low-viscosity liquid epoxidized aromatic hyperbranched polymers. Eur Polym J 42:711–714

Zhao S, Wang Z, Zhang W, Li J, Zhang S, Huang A (2018) Dopamine-mediated pre-crosslinked cellulose/polyurethane block elastomer for the preparation of robust biocomposites. ACS Omega 3:10657–10667

Zuluaga R, Putaux JL, Restrepo A, Mondragon I, Ganán P (2007) Cellulose microfibrils from banana farming residues: isolation and characterization. Cellulose 14:585–592

Acknowledgments

The authors acknowledge Mr. Joston P. Nongkynrih and Mr. Dannis Bareh of Sophisticated Analytical Instrument Facility (SAIF), North-Eastern Hills University, Shillong for helping with the TEM analysis and Sophisticated Analytical Instrumentation Centre (SAIC), Tezpur University, Tezpur for different analytical support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saikia, A., Debbarma, N. & Karak, N. Renewable resource based hyperbranched epoxy thermosetting nanocomposite with cellulose nanofiber as a sustainable material. Cellulose 26, 4743–4755 (2019). https://doi.org/10.1007/s10570-019-02443-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02443-8