Abstract

Tissue paper that is prepared from bamboo has a very promising future in the world, especially in China, thanks to the various merits of bamboo fibers. However, the water absorption behavior and mechanical properties of bamboo pulp based tissue paper need to be improved due to the inherent drawbacks of bamboo fiber, such as high stiffness, weak interaction between bamboo fibers etc. Hence, cellulose nanofibers (CNFs) were combined with bamboo fibers before the tissue paper-making process, to improve the water absorption behavior and mechanical properties of tissue paper. The hypotheses are that: (1) CNFs themselves possess large specific surface area and abundant hydroxyl groups as well, thus enhancing the hydrophilicity of tissue paper; and (2) the added CNFs can form 3D structures in tissue paper, thus providing abundant pores with uniform small size, which would facilitate the capillary effect for water absorption; and (3) more hydrogen bonds will be formed between CNF and bamboo fibers, thus improving the strength properties of tissue paper, thanks to the excellent mechanical and physical properties of CNF. The results from water absorption and tensile strength tests of bamboo handsheets indicated that the addition of CNFs can increase the water absorption capacity from 6.6 to 8.7 g/g when the CNF dosage was 10 wt% (based on the dried pulp). The water retention value of prepared bamboo fibers increased from 163 to 190% at the same CNF dosage, the tensile index increased from 18.5 to 24.5 N m/g as well. The results from the bulk and pore size analyses, FTIR, as well as SEM images of tissue paper also evidenced the conclusions above.

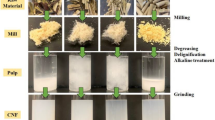

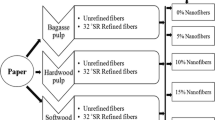

Graphical abstract

Cellulose nanofiber (CNF) as a versatile filler for the preparation of bamboo pulp based tissue paper with improved water absorption behavior and mechanical properties

Similar content being viewed by others

References

Abitbol T, Rivkin A, Cao Y, Nevo Y, Abraham E, Ben-Shalom T, Lapidot S, Shoseyov O (2016) Nanocellulose, a tiny fiber with huge applications. Curr Opin Biotechnol 39:76–88

An X, Wen Y, Almujil A, Cheng D, Li J, Jia X, Zou J, Ni Y (2016a) Nano-fibrillated cellulose (NFC) as versatile carriers of TiO2 nanoparticles (TNPs) for photocatalytic hydrogen generation. RSC Adv 6(92):89457–89466

An X, Wen Y, Cheng D, Zhu X, Ni Y (2016b) Preparation of cellulose nano-crystals through a sequential process of cellulase pretreatment and acid hydrolysis. Cellulose 23(4):2409–2420

An X, Cheng D, Dai L, Wang B, Ocampo HJ, Nasrallah J, Jia X, Zou J, Long Y, Ni Y (2017) Synthesis of nano-fibrillated cellulose/magnetite/titanium dioxide (NFC@Fe3O4@TNP) nanocomposites and their application in the photocatalytic hydrogen generation. Appl Catal B Environ 206:53–64

Arni SA (2018) Extraction and isolation methods for lignin separation from sugarcane bagasse: a review. Ind Crops Prod 115:330–339

Bajpai P (2016) Chapter 2—global pulp and paper production and consumption. In: Bajpai P (ed) Pulp and paper industry. Elsevier, Amsterdam, pp 9–14

Barneto AG, Carmona JA, Alfonso JEM, Serrano RS (2010) Simulation of the thermogravimetry analysis of three non-wood pulps. Biores Technol 101(9):3220–3229

Boufi S, González I, Delgado-Aguilar M, Tarrès Q, Pèlach MÀ, Mutjé P (2016) Nanofibrillated cellulose as an additive in papermaking process: a review. Carbohydr Polym 154:151–166

Buson RF, Melo LFL, Oliveira MN, Rangel GAVP, Deus EP (2018) Physical and mechanical characterization of surface treated bamboo fibers. Sci Technol Mater 30:67–73

Cohen A (2008) Package size and price discrimination in the paper towel market. Int J Ind Organ 26(2):502–516

Dai L, Long Z, Chen J, An X, Cheng D, Khan A, Ni Y (2017) Robust guar gum/cellulose nanofibrils multilayer films with good barrier properties. ACS Appl Mater Interfaces 9(6):5477–5485

Du L, Li Y, Lee S, Wu Q (2014) Water absorption properties of heat-treated bamboo fiber and high density polyethylene composites. BioResources 9(1):1189–1200

Fan M, Dai D, Huang B (2012) Fourier transform infrared spectroscopy for natural fibres. Fourier transform-materials analysis. InTech, London, pp 45–68

Fang L, Zheng M, Liu G, Zhao Y, Liu W, Huang L, Guo L (2017) Unexpected promotion of PCDD/F formation by enzyme-aided Cl2 bleaching in non-wood pulp and paper mill. Chemosphere 168:523–528

Fang C-H, Jiang Z-H, Sun Z-J, Liu H-R, Zhang X-B, Zhang R, Fei B-H (2018) An overview on bamboo culm flattening. Constr Build Mater 171:65–74

García A, Gandini A, Labidi J, Belgacem N, Bras J (2016) Industrial and crop wastes: a new source for nanocellulose biorefinery. Ind Crops Prod 93:26–38

Huang Z, Sun Y, Musso F (2018) Hygrothermal performance of natural bamboo fiber and bamboo charcoal as local construction infills in building envelope. Constr Build Mater 177:342–357

Jia M, Sun M, Li X, Xu X, Wang Y, Shi L, Hu H (2018) A new era of straw-based pulping? Evidence from a carbon metabolism perspective. J Clean Prod 193:327–337

Jiang F, Hsieh Y-L (2014) Super water absorbing and shape memory nanocellulose aerogels from TEMPO-oxidized cellulose nanofibrils via cyclic freezing–thawing. J Mater Chem A 2(2):350–359

Jin H, Cao A, Shi E, Seitsonen J, Zhang L, Ras RHA, Berglund LA, Ankerfors M, Walther A, Ikkala O (2013) Ionically interacting nanoclay and nanofibrillated cellulose lead to tough bulk nanocomposites in compression by forced self-assembly. J Mater Chem B 1(6):835–840

Keshavarzi N, Mashayekhy Rad F, Mace A, Ansari F, Akhtar F, Nilsson U, Berglund L, Bergstrom L (2015) Nanocellulose-zeolite composite films for odor elimination. ACS Appl Mater Interfaces 7(26):14254–14262

Khambhaty Y, Akshaya R, Rama Suganya C, Sreeram KJ, Raghava Rao J (2018) A logical and sustainable approach towards bamboo pulp bleaching using xylanase from Aspergillus nidulans. Int J Biol Macromol 118:452–459

Kim HJ et al (2006) Tensile properties and water absorption behavior of bamboo fiber reinforced composites. Key Eng Mater 306–308:417–422

Kushwaha PK, Kumar R (2010) Studies on the water absorption of bamboo-epoxy composites: the effect of silane treatment. Polym Plast Technol Eng 49(9):867–873

Li F, Mascheroni E, Piergiovanni L (2015) The potential of nanocellulose in the packaging field: a review. Packag Technol Sci 28(6):475–508

Liimatainen H, Ezekiel N, Sliz R, Ohenoja K, Sirvio JA, Berglund L, Hormi O, Niinimaki J (2013) High-strength nanocellulose-talc hybrid barrier films. ACS Appl Mater Interfaces 5(24):13412–13418

Liu L, Kerr WL, Kong F, Dee DR, Lin M (2018) Influence of nano-fibrillated cellulose (NFC) on starch digestion and glucose absorption. Carbohydr Polym 196:146–153

Lu H-F, Cai C-J, Zeng X-S, Campbell DE, Fan S-H, Liu G-L (2018) Bamboo versus crops: an integrated emergy and economic evaluation of using bamboo to replace crops in south Sichuan Province, China. J Clean Prod 177:464–473

Maaoui A, Haouari M, Bel Haj Mohamed N, Ben Ouada H, Bulou A (2017) Removal of hydroxyl groups from Er3 +/Yb3 + codoped flurotellurite glasses. Mater Res Bull 93:325–332

Meng Q, Li B, Li T, Feng X-Q (2018) Effects of nanofiber orientations on the fracture toughness of cellulose nanopaper. Eng Fract Mech 194:350–361

Mondal S (2017) Preparation, properties and applications of nanocellulosic materials. Carbohydr Polym 163:301–316

Nirmala C, Bisht MS, Bajwa HK, Santosh O (2018) Bamboo: a rich source of natural antioxidants and its applications in the food and pharmaceutical industry. Trends Food Sci Technol 77:91–99

Perremans D, Trujillo E, Ivens J, Van Vuure AW (2018) Effect of discontinuities in bamboo fibre reinforced epoxy composites. Compos Sci Technol 155:50–57

Shah DU, Sharma B, Ramage MH (2018) Processing bamboo for structural composites: influence of preservative treatments on surface and interface properties. Int J Adhes Adhes 85:15–22

Shatalov AA, Pereira H (2008) Arundo donax L. reed: new perspectives for pulping and bleaching. 5. Ozone-based TCF bleaching of organosolv pulps. Biores Technol 99(3):472–478

Srinivasan AK, Blomquist GC (2009) Ecolabeled paper towels: consumer valuation and expenditure analysis. J Environ Manag 90(1):314–320

Sugesty S, Kardiansyah T, Hardiani H (2015) Bamboo as raw materials for dissolving pulp with environmental friendly technology for rayon fiber. Procedia Chem 17:194–199

Venturi D, Grupkovic D, Sisti L, Baschetti MG (2018) Effect of humidity and nanocellulose content on Polyvinylamine-nanocellulose hybrid membranes for CO2 capture. J Membr Sci 548:263–274

Waldvogel HBG (1988) Two layer papermaching embossing fabric with depressions in the upper fabric layer for the production of tissue paper. U.S. Patent, No. 4,759,391(Washington, DC: U.S. Patent and Trademark Office)

Wang L (2001) Section 2—sanitary napkins. In: Osada Y, Kajiwara K, Fushimi T, Irasa O, Hirokawa Y, Matsunaga T, Shimomura T, Wang L, Ishida H (eds) Gels handbook. Academic Press, Burlington, pp 21–34

Wang F, Drzal LT (2018) The use of cellulose nanofibrils to enhance the mechanical properties of graphene nanoplatelets papers with high electrical conductivity. Ind Crops Prod 124:519–529

Waterhouse JF (2001) Paper products: classification. In: Encyclopedia of materials: science and technology (second edition), pp 6685–6696

Zhang H, Liu J, Guan M et al (2018) Nanofibrillated cellulose (NFC) as a pore size mediator in the preparation of thermally resistant separators for lithium ion batteries. ACS Sustain Chem Eng 6(4):4838–4844

Zhao HP, Feng XQ (2007) Ultrasonic technique for extracting nanofibers from nature materials. Appl Phys Lett 90:073112

Acknowledgments

The authors would like to acknowledge the financial support from the National Key Research and Development Plan (Grant 2017YFB0307902), the National Natural Science Foundation of China (Grant 31670589), the Canada Research Chairs program of the Government of Canada, the basic scientific research operation foundation of Tianjin University of Science and Technology (Grant: 000040186), the research fund of Tianjin Key Laboratory of Pulp and Paper, China (Grant: 201806), the research fund of Zhejiang JingXing Paper Joint Stock Co., Ltd (Grant: 21843), and the Opening Project of Guangxi Key Laboratory of Clean Pulp and Papermaking and Pollution Control, Nanning 530004, P.R. China (Grant: KF201815-4).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guan, M., An, X. & Liu, H. Cellulose nanofiber (CNF) as a versatile filler for the preparation of bamboo pulp based tissue paper handsheets. Cellulose 26, 2613–2624 (2019). https://doi.org/10.1007/s10570-018-2212-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2212-6