Abstract

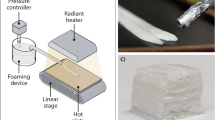

We describe a novel method for the production of lightweight fibrous structures of densities as low as 8.8 kg m\(^{-3}\). The method is based on the use of liquid foam as a carrier medium for dispersed Kraft fibres. Different to the process of foam forming, where the quick removal of the foam results in the formation of thin fibrous sheets, our samples are allowed to slowly drain and dry until all foam has disappeared. This procedure results in bulk samples whose height (up to 25 mm) and density are controlled by initial fibre concentration and liquid fraction of the foam. Above a minimum density, the compression modulus of elasticity of the samples increases linearly with density. Furthermore, we show compressive strength of the structures being controlled via the initial liquid fraction of the foam, making this an important process parameter for the fabrication of such structures.

Graphical abstract

Similar content being viewed by others

References

Al-Qararah A, Ekman A, Hjelt T, Kiiskinen H, Timonen J, Ketoja J (2016) Porous structure of fibre networks formed by a foaming process: a comparative study of different characterization techniques. J Microsc 264(1):88–101

Al-Qararah A, Hjelt T, Kinnunen K, Beletski N, Ketoja J (2012) Exceptional pore size distribution in foam-formed fibre networks. Nordic Pulp Paper Res J 27(2):226–230

Al-Qararah A, Hjelt T, Koponen A, Harlin A, Ketoja J (2013) Bubble size and air content of wet fibre foams in axial mixing with macro-instabilities. Coll Surf A Physicochem Eng Asp 436(Supplement C):1130–1139

Alimadadi M, Uesaka T (2016) 3d-oriented fiber networks made by foam forming. Cellulose 23(1):661–671

Bs EN 826 (1996) Thermal insulation products for building applications. Determination of compression behaviour, Standard, European Standardization Organisation (ESO)

Gu H, Wang J, Yu C (2016) Three-dimensional modeling of percolation behavior of electrical conductivity in segregated network polymer nanocomposites using monte carlo method. Adv Mater 5(1):1–8

Haffner B, Dunne F, Burke S, Hutzler S (2017) Ageing of fibre-laden aqueous foams. Cellulose 24(1):231–239

Härkäsalmi T, Lehmonen J, Itälä J, Peralta C, Siljander S, Ketoja J (2017) Design-driven integrated development of technical and perceptual qualities in foam-formed cellulose fibre materials. Cellulose 24(11):5053–5068

Lee J, Nikolov A, Wasan D (2014) Foam stability: the importance of film size and the micellar structuring phenomenon. Can J Chem Eng 92(12):2039–2045

Lehmonen J, Jetsu P, Kinnunen K, Hjelt T (2013) Potential of foam-laid forming technology in paper applications. Nordic Pulp Paper Res J 28(3):392–398

Madani A, Zeinoddini S, Varahmi S, Turnbull H, Phillion AB, Olson JA, Martinez DM (2014) Ultra-lightweight paper foams: processing and properties. Cellulose 21(3):2023–2031

Poehler T, Jetsu P, Fougeron A, Barraud V (2017) Use of papermaking pulps in foam-formed thermal insulation materials. Nordic Pulp Paper Res J 32(3):367–374

Radvan B (1964) Basic radfoam process. Br Pat 1329409(0):20

Schneider C, Rasband W, Eliceiri K (2012) Nih image to imagej: 25 years of image analysis. Nat Methods 9(7):671–675

Timofeev O, Jetsu P, Kiiskinen H, Keränen J (2016) Drying of foam-formed mats from virgin pine fibers. Dry Technol 34(10):1210–1218

Verbist G, Weaire D, Kraynik AM (1996) The foam drainage equation. J Phys Condens Matter 8:3715–3731

Acknowledgments

We thank D. Weaire and J. Ketoja for critical comments in laying out the manuscript. We also thank B. Haffner for his assistance on the project. This publication has emanated from research supported in part by a research grant from Science Foundation Ireland (SFI) under Grant Number 13/IA/1926. We also acknowledge the support of cost action MP1305 ‘Flowing matter’ and the European Space Agency ESA, Project microG-Foam, AO-99-075 and Contract 4000115113, ‘Soft Matter Dynamics’. T. Hjelt is supported by the Academy of Finland (Project “Surface interactions and rheology of aqueous cellulose-based foams”).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Burke, S.R., Möbius, M.E., Hjelt, T. et al. Properties of lightweight fibrous structures made by a novel foam forming technique. Cellulose 26, 2529–2539 (2019). https://doi.org/10.1007/s10570-018-2205-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2205-5