Abstract

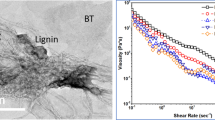

In this work, the potential replacement of xanthan gum (XGD) by cellulose nanofibrils in the composition of water based muds (WBMs) was studied. Bleached (B-CNF) and unbleached (L-CNF) cellulose nanofibrils, mainly differentiated by their lignin content, were tested and their performances were compared with that of XGD. The effects of cellulose nanofibrils on the rheological and filtration properties of WBMs were investigated. Rheometric analysis showed a shear-thinning behavior more noticeable for fluids containing B-CNF and XGD, while filtration properties were improved using L-CNF. The Sisko model was used to determine rheological parameters. Finally, it was found that by replacing XGD by double concentration of L-CNF in a WBM for Argentina shale, similar rheological properties were obtained. Structural changes were assessed by using Scanning Electron Microscopy (SEM). Particles agglomeration and good film formability were observed. Furthermore, WBMs with lignin-containing cellulose nanofibrils exhibited a better thermal stability after aging.

Graphical abstract

(with permission from American Chemical Society, 2018)

Similar content being viewed by others

Abbreviations

- A :

-

Cross section area in Eq. (1)

- BT:

-

Bentonite

- B-CNF:

-

Fully-bleached cellulose nanofibrils

- CNF:

-

Cellulose nanofibrils

- L-CNF:

-

Lignin-containing cellulose nanofibrils

- OBMs:

-

Oil based muds

- PAC:

-

Polyanionic cellulose

- S-BCNF:

-

Systems of fluids containing BT, B-CNF, PAC and H2O

- S-LCNF:

-

Systems of fluids containing BT, L-CNF, PAC and H2O

- S-XGD:

-

Systems of fluids containing BT, XGD, PAC and H2O

- WBMs:

-

Water based muds

- XGD:

-

Xanthan gum

- k :

-

Flow consistency coefficient at low shear rate (mPa·s)

- K c :

-

Permeability (mD)

- n :

-

Flow behavior index

- q :

-

Filtrate rate (cm3/s)

- t c :

-

Thickness of filter cake (cm)

- \(\dot{\gamma }\) :

-

Shear rate (1/s)

- \(\Delta P\) :

-

Pressure difference (6.80 atm)

- \(\eta_{\infty }\) :

-

Viscosity at infinite shear rate (mPa·s)

- \(\mu\) :

-

Viscosity of the filtrate at 25 °C (1.00 cP)

References

Abu-Jdayil B, Ghannam M (2014) The modification of rheological properties of sodium bentonite-water dispersions with low viscosity CMC polymer effect. Energy Sources A 36:1037–1048

Aftab A, Ismail AR, Ibupoto ZH, Akeiber H, Malghani MGK (2017) Nanoparticles based drilling muds a solution to drill elevated temperature wells: a review. Renew Sustain Energy Rev 76:1301–1313

American Petroleum Institute (2003) Recommended practice for field testing of water-based drilling fluids, 3rd ed. American Petroleum Institute, washington, DC, p 82. ANSI/API 13B-1, 1 November 2003

Baker Hughes INTEQ (1999) FLUID facts engineering handbook. Part Number 008902097 Rev. C, December

Barry MM, Jung Y, Lee JK, Phuoc TX, Chyu MK (2015) Fluid filtration and rheological properties of nanoparticle additive and intercalated clay hybrid bentonite drilling fluids. J Pet Sci Eng 127:338–346

Benyounes K, Mellak A, Benchabane A (2010) The effect of carboxymethylcellulose and xanthan on the rheology of bentonite suspensions. Energy Sources A 32(17):1634–1643

Bian H, Chen L, Gleisner R, Dai H, Zhu JY (2017) Producing wood-based nanomaterials by rapid fractionation of wood at 80 °C using a recyclable acid hydrotrope. Green Chem 19:3370–3379

Brebu M, Vasile C (2010) Thermal degradation of lignin: a review. Cellulose Chem Technol 44:353–363

Busch A, Myrseth V, Khatibi M, Skjetne P, Hovda S, Johansen ST (2018) Rheological characterization of polyanionic cellulose solutions with application to drilling fluids and cuttings transport modeling. Appl Rheol 28:1–16

Caenn R, Chillingar GV (1996) Drilling fluids: state of the art. J Pet Sci Eng 14:221–230

Capadona JR, Van Den Berg O, Capadona LA, Schroeter M, Rowan SJ, Tyler DJ, Weder C (2007) A versatile approach for the processing of polymer nanocomposites with self-assembled nanofibre templates. Nat Nanotechnol 2:765–769

Carico RD, Bagshaw FR (1978) Description and use of polymers used in drilling, workovers, and completions. SPE Paper 7747. SPE Production technology symposium, Hobbs, New Mexico, 30–31 October

Cheraghian G, Hemmati M, Masihi M, Bazgir S (2013) An experimental investigation of the enhanced oil recovery and improved performance of drilling fluids using titanium dioxide and fumed silica nanoparticles. J Nanostruct Chem 3:78

Darley HCH, Gray GR (1988) Composition and properties of drilling and completion fluids, 6th edn. Gulf Publ Co, Houston

De France KJ, Hoare T, Cranston ED (2017) Review of hydrogels and aerogels containing nanocellulose. Chem Mater 29:4609–4631

Diop CIK, Tajvidi M, Bilodeau MA, Bousfield DW, Hunt JF (2017) Isolation of lignocellulose nanofibrils (LCNF) and application as adhesive replacement in wood composites: example of fiberboard. Cellulose 24:3037–3050

Du X, Zhang Z, Liu W, Deng Y (2017) Nanocellulose-based conductive materials and their emerging applications in energy devices-a review. Nano Energy 35:299–320

Ezell RG, Ezzat AM, Horton D (Halliburton), Partain E (The DOW Chemical Company) (2010) State of art Polymers fulfill the need for high temperature clay free drill in and completion fluids. In: AADE Paper AADE-10-DF-HO-01 conference and exhibition, Houston, Texas, 6–7 April

Fazelabdolabadi B, Khodadadi A, Sedaghatzadeh M (2014) Thermal and rheological properties improvement of drilling fluids using functionalized carbon nanotubes. Appl Nanosci 5:651–659

Fenner RA, Lephardt JO (1981) Examination of the thermal decomposition of Kraft pine lignin by Fourier transform infrared evolved gas analysis. J Agric Food Chem 29:846–849

Ferrer A, Quintana E, Filpponen I, Solala I, Vidal T, Rodríguez A, Laine J, Rojas OJ (2012) Effect of residual lignin and heteropolysaccharides in nanofibrillar cellulose and nanopaper from wood fibers. Cellulose 19:2179–2193

Gao C (2015) Potential of welan gum as mud thickener. J Pet Explor Prod Technol 5:109–112

Hamed SB, Belhadri M (2009) Rheological properties of biopolymers drilling fluids. J Pet Sci Eng 67:84–90

Hebbar RS, Isloor AM, Ismail AF (2014) Preparation and evaluation of heavy metal rejection properties of polyetherimide/porous activated bentonite clay nanocomposite membrane. RSC Adv 4:47240–47248

Herrick F, Casebier R, Hamilton J, Sandberg K (1983) Microfibrillated cellulose: morphology and accessibility. J Appl Polym Sci Appl Polym Symp 37:797–813

Horvath AE, Lindström T, Laine J (2006) On the indirect polyelectrolyte titration of cellulosic fibers. Conditions for charge stoichiometry and comparison with ESCA. Langmuir 22:824–830

Hu W, Chen S, Liu L, Ding B, Wang H (2011) Formaldehyde sensors based on nanofibrous polyethyleneimine/bacterial cellulose membranes coated quartz crystal microbalance. Sens Actuators B 157:554–559

Hubbe MA, Ferrer A, Tyagi P, Yin Y, Salas C, Pal L, Rojas OJ (2017) Nanocellulose in thin films, coatings, and plies for packaging applications: a review. BioResources 12:2143–2233

Iscan AG, Kok MV (2007) Effects of polymers and CMC concentration on rheological and fluid loss parameters of water-based drilling fluids. Energy Sources A 29:939–949

Ismail A, Aftab A, Ibupoto Z, Zolkifile N (2016) The novel approach for the enhancement of rheological properties of water-based drilling fluids by using multi-walled carbon nanotube, nanosilica and glass beads. J Pet Sci Eng 139:264–275

Jang H, Zhang K, Chon BH, Choi HJ (2015) Enhanced oil recovery performance and viscosity characteristics of polysaccharide xanthan gum solution. J Ind Eng Chem 21:741–745

Jorfi M, Roberts MN, Foster EJ, Weder C (2013) Physiologically responsive, mechanically adaptive bio-nanocomposites for biomedical applications. ACS Appl Mater Interfaces 5:1517–1526

Jung Y, Son Y, Lee J, Phuoc TX, Soong Y, Chyu MK (2011) Rheological behavior of clay a nanoparticle hybrid-added bentonite suspensions: specific role of hybrid additives on the gelation of clay-based fluids. ACS Appl Mater Interfaces 3:3515–3522

Kargarzadeh H, Mariano M, Huang J, Lin N, Ahmad I, Dufresne A, Thomas S (2017) Recent developments on nanocellulose reinforced polymer nanocomposites: a review. Polymer 132:368–393

Khodja M, Canselier JP, Cohaut N, Bergaya F (2010a) Drilling fluid technology: performances and environmental considerations. Products and Services from R&D to final solutions Igor Fuerstner, pp 227–256

Khodja M, Canselier JP, Bergaya F, Fourar K, Khodja M, Cohaut N, Benmounah A (2010b) Shale problems and water-based drilling fluid optimisation in the Hassi Messaoud Algerian oil field. Appl Clay Sci 49:383–393

Kim HS, Kim S, Kim HJ, Yang HS (2006) Thermal properties of bio-flour-filled polyolefin composites with different compatibilizing agent type and content. Thermochim Acta 451:181–188

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466

Kosynkin DV, Ceriotti G, Wilson KC, Lomeda JR, Scorsone JT, Patel AD, Friedheim JE, Tour JM (2011) Graphene oxide as a high-performance fluid-loss-control additive in water-based drilling fluids. ACS Appl Mater Interfaces 4:222–227

Lahtinen P, Liukkonen S, Pere J, Sneck A, Kangas H (2014) A comparative study of fibrillated fibers from different mechanical and chemical pulps. BioResources 9:2115–2127

Li M, Wu Q, Song K, Lee S, Jin C, Ren S, Lei T (2015a) Soy protein isolate as fluid loss additive in bentonite water-based drilling fluids. ACS Appl Mater Interfaces 7:24799–24809

Li MC, Wu Q, Song K, Lee S, Qing Y, Wu Y (2015b) Cellulose nanoparticles: structure-morphology-rheology relationships. ACS Sustain Chem Eng 3:821–832

Li MC, Wu Q, Song K, De Hoop CF, Lee S, Qing Y, Wu Y (2015c) Cellulose nanocrystals and polyanionic cellulose as additives in bentonite water-based drilling fluids: rheological modeling and filtration mechanisms. Ind Eng Chem Res 55:133–143

Li MC, Wu Q, Song K, Qing Y, Wu Y (2015d) Cellulose nanoparticles as modifiers for rheology and fluid loss in bentonite water-based fluids. ACS Appl Matter Interfaces. 7:5006–5016

Li MC, Wu Q, Song K, French AD, Mei C, Lei T (2018) pH-responsive water-based drilling fluids containing bentonite and chitin nanocrystals. ACS Sustain Chem Eng 6:3783–3795

Liu J, Qiu Z, Huang W (2015) Novel latex particles and aluminum complexes as potential shale stabilizers in water-based drilling fluids. J Pet Sci Eng 135:433–441

Luckham PF, Rossi S (1999) The colloidal and rheological properties of bentonite suspensions. Adv Colloid Interface Sci 82:43–92

Mahfoudhi N, Boufi S (2017) Nanocellulose as a novel nanostructured adsorbent for environmental remediation: a review. Cellulose 24:1171–1197

Mahto V, Sharma VP (2004) Rheological study of a water based oil well drilling fluid. J Pet Sci Eng 45:123–128

Mao H, Qiu Z, Shen Z, Huang W (2015) Hydrophobic associated polymer based silica nanoparticles composite with core-shell structure as a filtrate reducer for drilling fluid at ultra-high temperature. J Pet Sci Eng 129:1–14

Marchetti L, Muzzio B, Cerrutti P, Andrés SC, Califano AN (2017) Bacterial nanocellulose as novel additive in low-lipid low-sodium meat sausages. Effect on quality and stability. Food Struct 14:52–59

Menezes RR, Marques LN, Campos LA, Ferreira HS, Santana LNL, Neves GA (2010) Use of statistical design to study the influence of CMC on the rheological properties of bentonite dispersions for water-based drilling fluids. Appl Clay Sci 49:13–20

Meng X, Zhang Y, Zhou F, Chu PK (2012) Effects of carbon ash on rheological properties of water-based drilling fluids. J Pet Sci Eng 100:1–8

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Morais JPS, de Freitas Rosa M, de sá Moreira SF, Nascimento LD, do Nascimento DM, Cassales AR (2013) Extraction and characterization of nanocellulose structures from raw cotton linter. Carbohydr Polym 91:229–235

Nair SS, Kuo PY, Chen H, Yan N (2017) Investigating the effect of lignin on the mechanical, thermal, and barrier properties of cellulose nanofibril reinforced epoxy composite. Ind Crops Prod 100:208–217

Nakagaito AN, Yano H (2004) The effect of morphological changes from pulp fiber towards nano-scale fibrillated cellulose on the mechanical properties of high-strength plant fiber based composites. Appl Phys A 78:547–552

Nakagaito AN, Iwamoto S, Yano H (2005) Bacterial cellulose: the ultimate nano-scalar cellulose morphology for the production of high-strength composites. Appl Phys A Mater Sci Process 80:93–97

Nasser J, Jesil A, Mohiuddin T, Al Ruqeshi M, Devi G, Mohataram S (2013) Experimental investigation of drilling fluid performance as nanoparticles. World J Nano Sci Eng 3:57–61

Navarrete RC, Seheult JM, Kelco, Oil Field Group a Division of CPKelco, Coffey MD (2001) New bio-polymers for drilling, drill-in, completions, spacer and coiled tubing applications part II. SPE Paper 64982. SPE International symposium on oilfield chemistry held. Houston, Texas, 13–16 February

Navarrete RC, Himes RE, Seheult JM (2000) Applications of xanthan gum in fluid-loss control and related formation damage. SPE Paper 59535, SPE permian basin oil gas recovery conferece. Midland, Texas, 21–23 March

Ng HM, Sin LT, Bee ST, Tee TT, Rahmat AR (2017) Review of nanocellulose polymer composite characteristics and challenges. Polym Plast Technol Eng 56:687–731

Nimeskern L, Martínez Ávila H, Sundberg J, Gatenholm P, Müller R, Stok KS (2013) Mechanical evaluation of bacterial nanocellulose as an implant material for ear cartilage replacement. J Mech Behav Biomed Mater 22:12–21

Nunes RDCP, Pires RV, Lucas EF, Vianna A, Lomba R (2014) New filtrate loss controller based on poly(methyl methacrylate-co-vinyl acetate). J Appl Polym Sci 131:1–7

Olatunde AO, Usman MA, Olafadehan OA, Adeosun TA, Ufot OE (2012) Improvement of rheological properties of drilling fluids using locally based materials. Pet Coal 54:65–72

Olsson RT, Kraemer R, Lopez-Rubio A, Torres-Giner S, Ocio MJ, Lagaron JM (2010) Extraction of microfibrils from bacterial cellulose networks for electrospinning of anisotropic biohybrid fiber yarns. Macromolecules 43(9):4201–4209

O’sullivan AC (1997) Cellulose: the structure slowly unravels. Cellulose 4(3):173–207

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromol 8(6):1934–1941

Panshin AJ, de Zeeuw C (1970) Textbook of Wood Technology. McGraw-Hill, NY, NY, p 705

Picheth GF, Sierakowski MR, Woehl MA, Pirich CL, Schreiner WH, Pontarolo R, De Freitas RA (2014) Characterisation of ultra-thin films of oxidised bacterial cellulose for enhanced anchoring and build-up of polyelectrolyte multilayers. Colloid Polym Sci 292:97–105

Pirich CL, de Freitas RA, Woehl MA, Picheth GF, Petri DFS, Sierakowski MR (2015) Bacterial cellulose nanocrystals: impact of the sulfate content on the interaction with xyloglucan. Cellulose 22:1773–1787

Postek MT, Vladar A, Dagata J, Farkas N, Ming B, Wagner R, Raman A, Moon RJ, Sabo R, Wegner TH, Beecher J (2011) Development of the metrology and imaging of cellulose nanocrystals. Meas Sci Technol 22:024005

Robert WA, Baker JR (1974) Use of guar gum and synthetic cellulose in oilfield stimulation fluids. In: SPE Paper 5005, 4th annual fall meeting of the society of petroleum engineers of AIME, Houston, Texas, 6–9 October

Rojo E, Peresin MS, Sampson WW, Hoeger IC, Vartiainen J, Laine J, Rojas OJ (2015) Comprehensive elucidation of the effect of residual lignin on the physical, barrier, mechanical and surface properties of nanocellulose films. Green Chem 17(3):1853–1866

Sayyadnejad M, Ghaffarian H, Saeidi M (2008) Removal of hydrogen sulfide by zinc oxide nanoparticles in drilling fluid. Int J Environ Sci Techol 5:565–569

Scallan AM, Grignon J (1979) The effect of cations on pulp and paper properties. Svensk Papperstidn 82(2):40–47

Seabra AB, Bernardes JS, Fávaro WJ, Paula AJ, Durán N (2018) Cellulose nanocrystals as carriers in medicine and their toxicities: a review. Carbohydr Polym 181:514–527

Sensoy T, Chenevert ME, Sharma MM (2009) Minimizing water invasion in shales using nanoparticles. In: SPE Paper 124429, SPE annual technical conference and exhibition. New Orleans, Louisiana, 4–7 October

Shah SN, Shanker NH, Ogugbue CC (2010) Future challenges of drilling fluids and their rheological measurements. In: AADE Paper AADE-10-DF-HO-41, conference and exhibition held at the Hilton Houston North, Houston, Texas, 6–7 April

Sharma MM, Chenevert ME, Guo Q, Ji L, Friedheim J, Zhang R (2012) A new family of nanoparticle based drilling fluids. In: SPE Paper 160045, SPE annual technical conference and exhibition. San Antonio, Texas, 8–10 October

Sjöström E (1993) Wood chemistry: fundamentals and applications, 2nd edn. Academic Press, San Diego

Solala I, Volperts A, Andersone A, Dizhbite T, Mironova-Ulmane N, Vehniäinen A, Vuorinen T (2012) Mechanoradical formation and its effects on birch kraft pulp during the preparation of nanofibrillated cellulose with Masuko refining. Holzforschung 66:477–483

Song K, Wu Q, Li M, Ren S, Dong L, Zhang X, Lei T, Kojima Y (2016a) Water-based bentonite drilling fluids modified by novel biopolymer for minimizing fluid loss and formation damage. Colloids Surf A Physicochem Eng Asp 507:58–66

Song K, Wu Q, Li MC, Wojtanowicz AK, Dong L, Zhang X, Ren S, Lei T (2016b) Performance of low solid bentonite drilling fluids modified by cellulose nanoparticles. J Nat Gas Sci Eng 34:1403–1411

Spence KL, Venditti RA, Habibi Y, Rojas OJ, Pawlak JJ (2010a) The effect of chemical composition on microfibrillar cellulose films from wood pulps: mechanical processing and physical properties. Bioresour Technol 101:5961–5968

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2010b) The effect of chemical composition on microfibrillar cellulose films from wood pulps: water interactions and physical properties for packaging applications. Cellulose 17:835–848

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2011) A comparative study of energy consumption and physical properties of microfibrillated cellulose produced by different processing methods. Cellulose 18:1097–1111

Tenhunen T, Peresin MS, Penttilä PA, Pere J, Serimaa R, Tammelin T (2014) Significance of xylan on the stability and water interactions of cellulosic nanofibrils. React Funct Polym 85:157–166

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci: Appl Polym Symp 37:815–827

Vänskä E, Vihelä T, Peresin MS, Vartiainen J, Hummel M, Vuorinen T (2016) Residual lignin inhibits thermal degradation of cellulosic fiber sheets. Cellulose 23:199–212

Villada Y, Gallardo F, Erdmann E, Casis N, Olivares L, Estenoz D (2017) Functional characterization on colloidal suspensions containing xanthan gum (XGD) and polyanionic cellulose (PAC) used in drilling fluids for a shale formation. Appl Clay Sci 149:59–66

Voisin H, Bergström L, Liu P, Mathew A (2017) Nanocellulose-based materials for water purification. Nanomaterials 7:57

Wang X, Cui X, Zhang L (2012) Preparation and characterization of lignin-containing nanofibrillar cellulose. Proc Environ Sci 16:125–130

Warren B, Van der Horst P, Stewart W (2003) Application of amphoteric cellulose ethers in drilling fluids. In: SPE Paper 80210, SPE international symposium on oilfield chemistry, Houston, Texas, 5–7 February

Xu X, Liu F, Jiang L, Zhu JY, Haagenson D, Wiesenborn DP (2013) Cellulose nanocrystals vs. cellulose nanofibrils: a comparative study on their microstructures and effects as polymer reinforcing agents. ACS Appl Mater Interfaces 5:2999–3009

Yan L, Wang C, Xu B, Sun J, Yue W, Yang Z (2013) Preparation of a novel amphiphilic comb-like terpolymer as viscosifying additive in low-solid drilling fluid. Mater Lett 105:232–235

Zhong H, Qiu Z, Huang W, Cao J (2012) Poly (oxypropylene)-amidoamine modified bentonite as potential shale inhibitor in water-based drilling fluids. Appl Clay Sci 67:36–43

Acknowledgments

The authors are thankful to Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET), Instituto Tecnológico de Buenos Aires (ITBA) and Universidad Nacional del Litoral (UNL) for the funding. Raquel Martin Sampedro and Maria Eugenia Eugenio from the National Institute of Agricultural and Food Research and Technology (INIA, Spain) are acknowledged for providing the cellulose pulps. CNF suspensions were produced under Panu Lahtinen from VTT Technical Research Center of Finland Ltd. (Espoo, Finland) is acknowledged for producing the CNF suspensions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Villada, Y., Iglesias, M.C., Casis, N. et al. Cellulose nanofibrils as a replacement for xanthan gum (XGD) in water based muds (WBMs) to be used in shale formations. Cellulose 25, 7091–7112 (2018). https://doi.org/10.1007/s10570-018-2081-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2081-z