Abstract

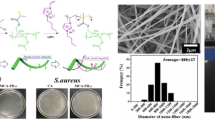

In consideration of the healthcare issues caused by Particulate Matter (PM) pollution, developing high-performance air-filter materials especially aiming at filtering PM2.5 has attracted great attention. In this work, we fabricated a novel air filter with spider-web-like structure based on renewable and biodegradable fibrillated cellulose fibers, and demonstrated an effective strategy for network structure regulation during freeze-drying process. The results showed that the air filter with spider-web-like structure, whose filtration efficiency for model PM particles with the diameter of 300 nm could exceed 99%, was obtained from a fibrillated cellulose fiber/water/Tert-Butyl Alcohol (TBA) mixture by freeze-drying. The role of TBA in the construction of spider-web-like structure was mainly due to the following two aspects: (1) TBA molecules could promote the separation of microfibrils which acted as the cobwebs in spider-web-like structure. (2) The presence of TBA resulted in air filter transformed from lamellar porous architecture into spider-web-like structure by changing the morphologies and growth kinetics of ice-crystals. Herein, this work paves a way to fabricate high-performance air filters based on renewable materials and the pore-formation mechanism can provide a guide for structure regulation in porous materials.

Similar content being viewed by others

References

Banavath HN, Bhardwaj NK, Ray AK (2011) A comparative study of the effect of refining on charge of various pulps. Bioresour Technol 102:4544–4551

Chem JM, Chun S, Choi E et al (2012) Eco-friendly cellulose nanofiber paper-derived separator membranes featuring tunable nanoporous network channels for lithium-ion batteries. J Mater Chem 22:16618–16626

Dash R, Li Y, Ragauskas AJ (2012) Cellulose nanowhisker foams by freeze casting. Carbohydr Polym 88:789–792

Deville S (2008) Freeze-casting of porous ceramics: a review of current achievements and issues. Adv Eng Mater 10:155–169

Deville S, Saiz E, Nalla RK, Tomsia AP (2006) Freezing as a path to build complex composites. Science 311:515–518

He M, Ichinose T, Kobayashi M et al (2016) Differences in allergic inflammatory responses between urban PM2.5 and fine particle derived from desert-dust in murine lungs. Toxicol Appl Pharmacol 297:41–55

Heydarifard S, Nazhad MM, Xiao H, Shipin O (2016) Water-resistant cellulosic filter for aerosol entrapment and water purification, part I: production of water-resistant cellulosic filter. Environ Technol 37:1716–1722

Hu X, Yang L, Li L et al (2016) Freeze casting of composite system with stable fiber network and movable particles. J Eur Ceram Soc 36:4147–4153

Jahangiri P, Madani A, Korehei R et al (2014) On filtration and heat insulation properties of foam formed cellulose based materials. Nord Pulp Pap 29:584–591

Jiang F, Hsieh Y (2014) Assembling and redispersibility of rice straw nanocellulose: effect of tert-butanol. ACS Appl Mater Interfaces 6:20075–20084

Kasraian K, DeLuca PP (1995) Thermal analysis of the tertiary butyl alcohol–water system and its implications on freeze-drying. Pharm Res 12:484–490

Khalil HPSA, Davoudpour Y, Islam N et al (2014) Production and modification of nanofibrillated cellulose using various mechanical processes: a review. Carbohydr Polym 99:649–665

Korehei R, Jahangiri P, Nikbakht A et al (2016) Effects of drying strategies and microfibrillated cellulose fiber content on the properties of foam-formed paper. J Wood Chem Technol 36:235–249

Lee CJ, Martin RV, Henze DK et al (2015) Response of global particulate-matter-related mortality to changes in local precursor emissions. Environ Sci Technol 49:4335–4344

Li S, Williams G, Guo Y (2016) Health benefits from improved outdoor air quality and intervention in China. Environ Pollut 214:17–25

Liu B, Zhang S, Wang X et al (2015) Efficient and reusable polyamide-56 nanofiber/nets membrane with bimodal structures for air filtration. J Colloid Interface Sci 457:203–211

MacFarlane AL, Kadla JF, Kerekes RJ (2012) High performance air filters produced from freeze-dried fibrillated wood pulp: fiber network compression due to the freezing process. Ind Eng Chem Res 51:10702–10711

Mao J, Grgic B, Finlay WH et al (2008) Wood pulp based filters for removal of sub-micrometer aerosol particles. Nord Pulp Pap 23:420–425

Nemoto J, Saito T, Isogai A (2015) Simple freeze-drying procedure for producing nanocellulose aerogel-containing, high-performance air filters. ACS Appl Mater Interfaces 7:19809–19815

Ni N, Tesconi M, Tabibi SE et al (2001) Use of pure t-butanol as a solvent for freeze-drying: a case study. Int J Pharm 226:39–46

Oh HJ, Pant HR, Kang YS et al (2012) Synthesis and characterization of spider-web-like electrospun mats of meta-aramid. Polym Int 61:1675–1682

Pant HR, Park CH, Tijing LD et al (2012) Bimodal fiber diameter distributed graphene oxide/nylon-6 composite nanofibrous mats via electrospinning. Colloids Surf A Physicochem Eng Asp 407:121–125

Pant HR, Kim HJ, Joshi MK et al (2014) One-step fabrication of multifunctional composite polyurethane spider-web-like nanofibrous membrane for water purification. J Hazard Mater 264:25–33

Sehaqui H, Salajková M, Zhou Q, Berglund LA (2010) Mechanical performance tailoring of tough ultra-high porosity foams prepared from cellulose I nanofiber suspensions. Soft Matter 6:1824–1832

Sehaqui H, Zhou Q, Berglund LA (2011) High-porosity aerogels of high specific surface area prepared from nanofibrillated cellulose (NFC). Compos Sci Technol 71:1593–1599

Shi L, Zhuang X, Tao X et al (2013) Solution blowing nylon 6 nanofiber mats for air filtration. Fibers Polym 14:1485–1490

Svagan AJ, Samir MASA, Berglund LA (2008) Biomimetic foams of high mechanical performance based on nanostructured cell walls reinforced by native cellulose nanofibrils. Adv Mater 20:1263–1269

Thiessen RJ (2006) Filtration of respired gases: theoretical aspects. Respir Care Clin N Am 12:183–201

Wang N, Wang X, Ding B et al (2012) Tunable fabrication of three-dimensional polyamide-66 nano-fiber/nets for high efficiency fine particulate filtration. J Mater Chem 22:1445–1452

Wang N, Zhu Z, Sheng J et al (2014) Superamphiphobic nanofibrous membranes for effective filtration of fine particles. J Colloid Interface Sci 428:41–48

Wang S, Peng X, Zhong L et al (2015) An ultralight, elastic, cost-effective, and highly recyclable superabsorbent from microfibrillated cellulose fibers for oil spillage cleanup. J Mater Chem A 3:8772–8781

Yang Y, Zhang S, Zhao X et al (2015) Sandwich structured polyamide-6/polyacrylonitrile nanonets/bead-on- string composite membrane for effective air filtration. Sep Purif Technol 152:14–22

Yoon Y, Kim S, Ahn KH, Ko KB (2016) Fabrication and characterization of micro-porous cellulose filters for indoor air quality control. Environ Technol 37:703–712

Zhang S, Tang N, Cao L et al (2016) Highly integrated polysulfone/polyacrylonitrile/polyamide-6 air filter for multilevel physical sieving airborne particles. ACS Appl Mater Interfaces 8:29062–29072

Zhang S, Liu H, Yin X et al (2017a) Tailoring mechanically robust poly(m-phenylene isophthalamide) nanofiber/nets for ultrathin high-efficiency air filter. Sci Rep 7:40550–40561

Zhang S, Liu H, Zuo F et al (2017b) A controlled design of ripple-like polyamide-6 nanofiber/nets membrane for high-efficiency air filter. Small 13:1603151–1603161

Zhao X, Wang S, Yin X et al (2016) Slip-effect functional air filter for efficient purification of PM2.5. Sci Rep 6:35472–35483

Acknowledgments

The authors would like to acknowledge the financial support from National Science Foundation of China (Grant No. 31670593), State Key Laboratory of Pulp and Paper Engineering (201601), State Key Laboratory for modification of chemical fibers and polymer materials (LK1601), Shaanxi Province as a Whole the Innovation Project of Science and Technology Plan Projects (2016KTCQ01-87), Education Department of Shaanxi Provincial Government (15JF012), and Science and Technology Department of Shaanxi Province (2015KJXX-34). We appreciate Suzhou Huada Instrument and Equipment LTD. very much for friendly providing tests for us.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Zhaoqing Lu and Zhiping Su have contributed equally to this work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lu, Z., Su, Z., Song, S. et al. Toward high-performance fibrillated cellulose-based air filter via constructing spider-web-like structure with the aid of TBA during freeze-drying process. Cellulose 25, 619–629 (2018). https://doi.org/10.1007/s10570-017-1561-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1561-x