Abstract

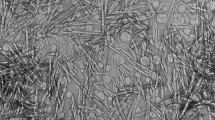

In this study, the surface polarity of sulfated crystalline nanocellulose (CNC) was tailored using an ecologically compatible surface modification strategy. Lauric arginate, a novel biologically-derived cationic surfactant, was ionically bonded to the CNC surface sulfate groups forming a monolayer that significantly increased surface hydrophobicity. Both unmodified (P-CNC) and surfactant modified (F-CNC) were incorporated into a non-polar PLA matrix to study their reinforcing effect. The P-CNC, ascribed to its inherent hydrophilic characteristic, had limited nucleating and reinforcing effect on the PLA matrix. Large nanoparticle aggregation and interface debonding were easily discernable in P-CNC/PLA nanocomposite films. The hydrophobic F-CNC, by contrast, had a much better dispersibility and interface compatibility within the PLA matrix. The cold crystallization rate, crystallinity, storage modulus (glassy and rubbery states), glass transition temperature, and tensile strength and modulus of F-CNC/PLA nanocomposite films were remarkably enhanced with appropriate loading level of F-CNC (<5 wt%). These results demonstrate an efficient route to increase the hydrophobicity of CNC for its enhanced nanoreinforcing effect in various non-polar matrices.

Similar content being viewed by others

References

Abitbol T, Marway H, Cranston ED (2014) Surface modification of cellulose nanocrystals with cetyltrimethylammonium bromide. Nordic Pulp Pap Res J 29:046–057

Ansari F, Salajková M, Zhou Q, Berglund LA (2015) Strong surface treatment effects on reinforcement efficiency in biocomposites based on cellulose nanocrystals in poly(vinyl acetate) matrix. Biomacromolecules 16:3916–3924

Ben Azouz K, Ramires EC, Van den Fonteyne W, El Kissi N, Dufresne A (2011) Simple method for the melt extrusion of a cellulose nanocrystal reinforced hydrophobic polymer. ACS Macro Lett 1:236–240

Bondeson D, Oksman K (2007) Dispersion and characteristics of surfactant modified cellulose whiskers nanocomposites. Compos Interfaces 14:617–630

Brinatti C, Huang J, Berry RM, Tam KC, Loh W (2016) Structural and energetic studies on the interaction of cationic surfactants and cellulose nanocrystals. Langmuir 32:689–698

Chi K, Catchmark JM (2017) Crystalline nanocellulose/lauric arginate complexes. Carbohydr Polym 175:320–329

Choi K-M, Choi M-C, Han D-H, Park T-S, Ha C-S (2013) Plasticization of poly(lactic acid) (PLA) through chemical grafting of poly(ethylene glycol) (PEG) via in situ reactive blending. Eur Polym J 49:2356–2364

Dhar P, Tarafder D, Kumar A, Katiyar V (2016) Thermally recyclable polylactic acid/cellulose nanocrystal films through reactive extrusion process. Polymer 87:268–282

Dufresne A (2013) Nanocellulose: a new ageless bionanomaterial. Mater Today 16:220–227

Dufresne A (2017) Cellulose nanomaterial reinforced polymer nanocomposites. Curr Opin Colloid Interface Sci 29:1–8

Farah S, Anderson DG, Langer R (2016) Physical and mechanical properties of PLA, and their functions in widespread applications—a comprehensive review. Adv Drug Deliv Rev 107:367–392

Favier V, Canova GR, Cavaillé JY, Chanzy H, Dufresne A, Gauthier C (1995a) Nanocomposite materials from latex and cellulose whiskers. Polym Adv Technol 6:351–355

Favier V, Chanzy H, Cavaille JY (1995b) Polymer nanocomposites reinforced by cellulose whiskers. Macromolecules 28:6365–6367

Follain N, Marais M-F, Montanari S, Vignon MR (2010) Coupling onto surface carboxylated cellulose nanocrystals. Polymer 51:5332–5344

Fortunati E et al (2012) Multifunctional bionanocomposite films of poly(lactic acid), cellulose nanocrystals and silver nanoparticles. Carbohydr Polym 87:1596–1605

Frone AN, Panaitescu DM, Chiulan I, Nicolae CA, Vuluga Z, Vitelaru C, Damian CM (2016) The effect of cellulose nanofibers on the crystallinity and nanostructure of poly(lactic acid) composites. J Mater Sci 51:9771–9791

Fujisawa S, Saito T, Kimura S, Iwata T, Isogai A (2013) Surface engineering of ultrafine cellulose nanofibrils toward polymer nanocomposite materials. Biomacromolecules 14:1541–1546

Fukushima K, Kimura Y (2006) Stereocomplexed polylactides (Neo-PLA) as high-performance bio-based polymers: their formation, properties, and application. Polym Int 55:626–642

Goffin A-L, Raquez J-M, Duquesne E, Siqueira G, Habibi Y, Dufresne A, Dubois P (2011) From interfacial ring-opening polymerization to melt processing of cellulose nanowhisker-filled polylactide-based nanocomposites. Biomacromolecules 12:2456–2465

Grunert M, Winter WT (2002) Nanocomposites of cellulose acetate butyrate reinforced with cellulose nanocrystals. J Polym Environ 10:27–30

Habibi Y, Goffin A-L, Schiltz N, Duquesne E, Dubois P, Dufresne A (2008) Bionanocomposites based on poly(ε-caprolactone)-grafted cellulose nanocrystals by ring-opening polymerization. J Mater Chem 18:5002–5010

Habibi Y, Aouadi S, Raquez J-M, Dubois P (2013) Effects of interfacial stereocomplexation in cellulose nanocrystal-filled polylactide nanocomposites. Cellulose 20:2877–2885

Hasani M, Cranston ED, Westman G, Gray DG (2008) Cationic surface functionalization of cellulose nanocrystals. Soft Matter 4:2238–2244

Herrera N, Mathew AP, Oksman K (2015) Plasticized polylactic acid/cellulose nanocomposites prepared using melt-extrusion and liquid feeding: mechanical, thermal and optical properties. Compos Sci Technol 106:149–155

Heux L, Chauve G, Bonini C (2000) Nonflocculating and chiral-nematic self-ordering of cellulose microcrystals suspensions in nonpolar solvents. Langmuir 16:8210–8212

Huang L, Ye Z, Berry R (2016) Modification of cellulose nanocrystals with quaternary ammonium-containing hyperbranched polyethylene ionomers by ionic assembly. ACS Sustain Chem Eng 4:4937–4950

Hubbe MA, Rojas OJ, Lucia LA (2015) Green modification of surface characteristics of cellulosic materials at the molecular or nano scale: a review. BioResources 10:6095–6206

Iwatake A, Nogi M, Yano H (2008) Cellulose nanofiber-reinforced polylactic acid. Compos Sci Technol 68:2103–2106

Jiang L, Wolcott MP, Zhang J (2006) Study of biodegradable polylactide/poly(butylene adipate-co-terephthalate) blends. Biomacromolecules 7:199–207

Johari AP, Mohanty S, Kurmvanshi SK, Nayak SK (2016) Influence of different treated cellulose fibers on the mechanical and thermal properties of poly(lactic acid). ACS Sustain Chem Eng 4:1619–1629

Kaleemullah M, Khan SU, Kim J-K (2012) Effect of surfactant treatment on thermal stability and mechanical properties of CNT/polybenzoxazine nanocomposites. Compos Sci Technol 72:1968–1976

Kaushik A, Singh M, Verma G (2010) Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carbohydr Polym 82:337–345

Khan A et al (2012) Mechanical and barrier properties of nanocrystalline cellulose reinforced chitosan based nanocomposite films. Carbohydr Polym 90:1601–1608

Kim J, Montero G, Habibi Y, Hinestroza JP, Genzer J, Argyropoulos DS, Rojas OJ (2009) Dispersion of cellulose crystallites by nonionic surfactants in a hydrophobic polymer matrix. Polym Eng Sci 49:2054–2061

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466

Lai S-M, Wu S-H, Lin G-G, Don T-M (2014) Unusual mechanical properties of melt-blended poly(lactic acid) (PLA)/clay nanocomposites. Eur Polym J 52:193–206

Li Z, Tan BH, Lin T, He C (2016) Recent advances in stereocomplexation of enantiomeric PLA-based copolymers and applications. Prog Polym Sci 62:22–72

Lin N, Huang J, Chang PR, Feng J, Yu J (2011) Surface acetylation of cellulose nanocrystal and its reinforcing function in poly(lactic acid). Carbohydr Polym 83:1834–1842

Lin N, Huang J, Dufresne A (2012) Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials: a review. Nanoscale 4:3274–3294

Liu H, Song W, Chen F, Guo L, Zhang J (2011) Interaction of microstructure and interfacial adhesion on impact performance of polylactide (PLA) ternary blends. Macromolecules 44:1513–1522

Ljungberg N, Bonini C, Bortolussi F, Boisson C, Heux L, Cavaillé J-Y (2005) New nanocomposite materials reinforced with cellulose whiskers in atactic polypropylene: effect of surface and dispersion characteristics. Biomacromolecules 6:2732–2739

Mangalam AP, Simonsen J, Benight AS (2009) Cellulose/DNA hybrid nanomaterials. Biomacromolecules 10:497–504

Misra M, Pandey JK, Mohanty A (2015) Biocomposites: design and mechanical performance, 1st edn. Woodhead Publishing, Sawston

Murariu M, Dubois P (2016) PLA composites: from production to properties. Adv Drug Del Rev 107:17–46

Murariu M et al (2011) High-performance polylactide/ZnO nanocomposites designed for films and fibers with special end-use properties. Biomacromolecules 12:1762–1771

Nagalakshmaiah M, El Kissi N, Dufresne A (2016a) Ionic compatibilization of cellulose nanocrystals with quaternary ammonium salt and their melt extrusion with polypropylene. ACS Appl Mater Interfaces 8:8755–8764

Nagalakshmaiah M, Pignon F, El Kissi N, Dufresne A (2016b) Surface adsorption of triblock copolymer (PEO–PPO–PEO) on cellulose nanocrystals and their melt extrusion with polyethylene. RSC Adv 6:66224–66232

Natterodt JC, Sapkota J, Foster EJ, Weder C (2017) Polymer nanocomposites with cellulose nanocrystals featuring adaptive surface groups. Biomacromolecules 18:517–525

Oksman K, Mathew AP, Bondeson D, Kvien I (2006) Manufacturing process of cellulose whiskers/polylactic acid nanocomposites. Compos Sci Technol 66:2776–2784

Paralikar SA, Simonsen J, Lombardi J (2008) Poly(vinyl alcohol)/cellulose nanocrystal barrier membranes. J Membr Sci 320:248–258

Park SH, Lee SG, Kim SH (2013) Isothermal crystallization behavior and mechanical properties of polylactide/carbon nanotube nanocomposites. Compos Part A Appl Sci Manuf 46:11–18

Pinazo A, Manresa MA, Marques AM, Bustelo M, Espuny MJ, Perez L (2016) Amino acid-based surfactants: new antimicrobial agents. Adv Colloid Interface Sci 228:17–39

Pretula J, Slomkowski S, Penczek S (2016) Polylactides—methods of synthesis and characterization. Adv Drug Del Rev 107:3–16

Qiao R, Deng H, Putz KW, Brinson LC (2011) Effect of particle agglomeration and interphase on the glass transition temperature of polymer nanocomposites. J Polym Sci Part B Polym Phys 49:740–748

Raquez JM, Murena Y, Goffin AL, Habibi Y, Ruelle B, DeBuyl F, Dubois P (2012) Surface-modification of cellulose nanowhiskers and their use as nanoreinforcers into polylactide: a sustainably-integrated approach. Compos Sci Technol 72:544–549

Raquez J-M, Habibi Y, Murariu M, Dubois P (2013) Polylactide (PLA)-based nanocomposites. Prog Polym Sci 38:1504–1542

Rasal RM, Janorkar AV, Hirt DE (2010) Poly(lactic acid) modifications. Prog Polym Sci 35:338–356

Reddy MM, Vivekanandhan S, Misra M, Bhatia SK, Mohanty AK (2013) Biobased plastics and bionanocomposites: current status and future opportunities. Prog Polym Sci 38:1653–1689

Saini P, Arora M, Kumar MNVR (2016) Poly(lactic acid) blends in biomedical applications. Adv Drug Del Rev 107:47–59

Sakakibara K, Yano H, Tsujii Y (2016) Surface engineering of cellulose nanofiber by adsorption of diblock copolymer dispersant for green nanocomposite materials. ACS Appl Mater Interfaces 8:24893–24900

San Román MS, Holgado MJ, Salinas B, Rives V (2013) Drug release from layered double hydroxides and from their polylactic acid (PLA) nanocomposites. Appl Clay Sci 71:1–7

Siracusa V, Rocculi P, Romani S, Dalla Rosa M (2008) Biodegradable polymers for food packaging: a review. Trends Food Sci Technol 19:634–643

Suryanegara L, Nakagaito AN, Yano H (2009) The effect of crystallization of PLA on the thermal and mechanical properties of microfibrillated cellulose-reinforced PLA composites. Compos Sci Technol 69:1187–1192

Suryanegara L, Nakagaito AN, Yano H (2010) Thermo-mechanical properties of microfibrillated cellulose-reinforced partially crystallized PLA composites. Cellulose 17:771–778

Tan BH, Muiruri JK, Li Z, He C (2016) Recent progress in using stereocomplexation for enhancement of thermal and mechanical property of polylactide. ACS Sustain Chem Eng 4:5370–5391

Tingaut P, Zimmermann T, Lopez-Suevos F (2009) Synthesis and characterization of bionanocomposites with tunable properties from poly(lactic acid) and acetylated microfibrillated cellulose. Biomacromolecules 11:454–464

Wang Y, Tian H, Zhang L (2010) Role of starch nanocrystals and cellulose whiskers in synergistic reinforcement of waterborne polyurethane. Carbohydr Polym 80:665–671

Xu X, Liu F, Jiang L, Zhu JY, Haagenson D, Wiesenborn DP (2013) Cellulose nanocrystals vs. cellulose nanofibrils: a comparative study on their microstructures and effects as polymer reinforcing agents. ACS Appl Mater Interfaces 5:2999–3009

Xu C, Lv Q, Wu D, Wang Z (2017) Polylactide/cellulose nanocrystal composites: a comparative study on cold and melt crystallization. Cellulose 24:2163–2175

Yasuniwa M, Sakamo K, Ono Y, Kawahara W (2008) Melting behavior of poly(l-lactic acid): X-ray and DSC analyses of the melting process. Polymer 49:1943–1951

Yu H, Yan C, Yao J (2014) Fully biodegradable food packaging materials based on functionalized cellulose nanocrystals/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) nanocomposites. RSC Adv 4:59792–59802

Zhang K, Mohanty AK, Misra M (2012) Fully biodegradable and biorenewable ternary blends from polylactide, poly(3-hydroxybutyrate-co-hydroxyvalerate) and poly(butylene succinate) with balanced properties. ACS Appl Mater Interfaces 4:3091–3101

Zhang K, Nagarajan V, Misra M, Mohanty AK (2014) Supertoughened renewable PLA reactive multiphase blends system: phase morphology and performance. ACS Appl Mater Interfaces 6:12436–12448

Zhang L, Li Y, Wang H, Qiao Y, Chen J, Cao S (2015) Strong and ductile poly(lactic acid) nanocomposite films reinforced with alkylated graphene nanosheets. Chem Eng J 264:538–546

Zhu A, Diao H, Rong Q, Cai A (2010) Preparation and properties of polylactide–silica nanocomposites. J Appl Polym Sci 116:2866–2873

Acknowledgments

We gratefully acknowledge the financial support from USDA Forest Service (Agreement No. 11-JV-11111129-121) and the Penn State College of Agricultural Sciences Graduate Student Competitive Grants Program. We also thank A&B Ingredients for providing the lauric arginate.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chi, K., Catchmark, J.M. Enhanced dispersion and interface compatibilization of crystalline nanocellulose in polylactide by surfactant adsorption. Cellulose 24, 4845–4860 (2017). https://doi.org/10.1007/s10570-017-1479-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1479-3