Abstract

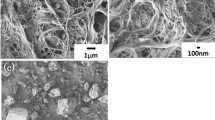

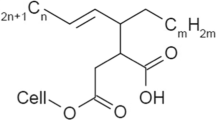

Microfibrillated cellulose (MFC) fibers were acylated by the sizing agent, alkenyl succinic anhydride (ASA) reagent in an aqueous medium, by simple impregnation. The chemical modification was confirmed by Fourier transform infrared spectroscopy and solid-state 13C NMR. All the samples were combined with low-density polyethylene and the morphology, thermal properties, mechanical properties and water absorption behavior of the ensuing composites were investigated. The chemical modification of the MFC with ASA improved the interfacial adhesion with the matrix and hence the mechanical properties of the composites while decreasing their water uptake capacity. In addition, it was shown that the degree of substitution strongly influenced the performance of the composites.

Similar content being viewed by others

References

Darie RN, Vlad S, Anghel N, Doroftei F, Tamminen T, Spiridon L (2014) New PP/PLA/cellulose composites: effect of cellulose functionalization on accelerated weathering behavior. Polym Adv Technol 26:941–952

Ellis B (2000) Polymers: a property database. CRC Press, Boca Raton

Faruk O, Bledzki AK, Fink HP, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37:1552–1596

Gu R, Sain M, Kokta BV (2015) Evaluation of wood composite additives in the mechanical property changes of PE blends. Polym Compos 36:287–293

Hagiopol C, Johnston JW (2011) Chemistry of modern papermaking. CRC Press, Boca Raton

Hubbe MA (2007) Paper’s resistance to wetting: a review of internal sizing chemicals and their effects. BioResources 2:106–145

Iwamoto S, Yamamoto S, Lee S-H, Endo T (2014) Mechanical properties of polypropylene composites reinforced by surface-coated microfibrillated cellulose. Compos Part A Appl Sci Manuf 59:26–29

Kitano T, Kataoka T, Nagatsuka Y (1984) Shear flow rheological properties of vinylon- and glass-fiber reinforced polyethylene melts. Rheol Acta 23:20–30

Li J, Zhang LP, Peng F et al (2009) Microwave-assisted solvent-free acetylation of cellulose with acetic anhydride in the presence of iodine as a catalyst. Molecules 14:3551–3566

Lindfors J, Salmi J, Laine J, Stenius P (2007) AKD and ASA model surfaces: preparation and characterization. BioResources 2:652–670

Lu J, Wang T, Drzal LT (2008) Preparation and properties of microfibrillated cellulose polyvinyl alcohol composite materials. Compos Part A Appl Sci Manuf 39:738–746

Panaitescu DM, Donescu D, Bercu C et al (2007a) Polymer composites with cellulose microfibrils. Polym Eng Sci 47:1228–1234

Panaitescu DM, Notingher PV, Ghiurea M et al (2007b) Properties of composite materials from polyethylene and cellulose microfibrils. J Optoelectron Adv Mater 9:2526–2528

Quillin DT, Caulfield DF, Koutsky JA (1992) Cellulose polypropylene composites: the use of AKD and ASA sizes as compatibilizers. Int J Polym Mater 17:215–227

Sato A, Kabusaki D, Okumura H et al (2016) Surface modification of cellulose nanofibers with alkenyl succinic anhydride for high-density polyethylene reinforcement. Compos Part A Appl Sci Manuf 83:72–79

Satyanarayana KG, Arizaga GGC, Wypych F (2009) Biodegradable composites based on lignocellulosic fibers: an overview. Prog Polym Sci 34:982–1021

Shalwan A, Yousif BF (2013) In state of art: mechanical and tribological behaviour of polymeric composites based on natural fibres. Mater Des 48:14–24

Siqueira G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 10:425–432

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Stamboulis A, Baillie CA, Garkhail SK et al (2000) Environmental durability of flax fibres and their composites based on polypropylene matrix. Appl Compos Mater 7:273–294

Wambua P, Ivens J, Verpoest I (2003) Natural fibres: can they replace glass in fibre reinforced plastics? Compos Sci Technol 63:1259–1264

Wang WJ, Wang WW, Shao ZQ (2014) Surface modification of cellulose nanowhiskers for application in thermosetting epoxy polymers. Cellulose 21:2529–2538

Yan Y, Amer H, Rosenau T et al (2016) Dry, hydrophobic microfibrillated cellulose powder obtained in a simple procedure using alkyl ketene dimer. Cellulose 23:1189–1197

Zhang H, Kannangara D, Hilder M et al (2007) The role of vapour deposition in the hydrophobization treatment of cellulose fibres using alkyl ketene dimers and alkenyl succinic acid anhydrides. Colloids Surf A Physicochem Eng Asp 297:203–210

Acknowledgments

The authors are thankful to Kruger Biomaterial Inc. (Trois-Rivières, Canada) for supplying MFC fibers as a raw material.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lepetit, A., Drolet, R., Tolnai, B. et al. Microfibrillated cellulose with sizing for reinforcing composites with LDPE. Cellulose 24, 4303–4312 (2017). https://doi.org/10.1007/s10570-017-1429-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1429-0