Abstract

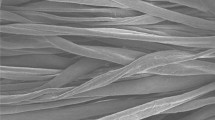

The aim of this study was to investigate the feasibility of the effect of CO2 laser technology on some physical and chemical properties of cotton-based fabrics. The cotton and cotton/polyester blended fabrics used in this study were treated with different combinations of laser processing parameters, i.e., resolution (52, 60 and 68 dpi) and pixel time (110, 120, 130 and 140 μs). After laser treatment, the surface structures of the fabric samples were evaluated by scanning electron microscope. It was confirmed that pores and cracks were formed on the laser-treated cotton fibres and their sizes varied with the change of laser processing parameters. However, the change occurring on cotton/polyester blended fabrics was found to be different such that the pores of cotton fibres were covered by the melted polyester with uneven flat regions being created. The results of fabric weight and fabric thickness revealed that laser treatment altered the weight of both cotton and cotton/polyester blended fabrics. However, the fabric thickness change of cotton/polyester blended fabrics was not steady when the laser processing parameters varied. Although laser treatment reduced the whiteness of both cotton and cotton/polyester blended fabrics, the whiteness was still acceptable. In addition, the laser processing parameter could affect the tensile strength of cotton and cotton/polyester blended fabrics. Surface chemical changes of cotton and cotton/polyester blended fabrics induced by laser irradiation were observed and analysed by Fourier transform infrared spectroscopy and X-ray photoelectron spectroscopy. The results revealed that the hydroxyl C–O was found disappeared and the ether –O– stretches were reduced in both types of fabrics. Finally, it was proved by the solubility test that during laser treatment, the cotton fibres would be etched away.

Similar content being viewed by others

References

Alonso H, Esteves F (2007) Effect of CO2 laser radiation on surface properties of synthetic fibres. Res J Text Appar 11(3):42–47

Card A, Moore MA, Ankeny M (2006) Garment washed jeans: impact of launderings on physical properties. Int J Cloth Sci Technol 18(1):43–52

Chen Z, Hay JN, Jenkins MJ (2012) FTIR spectroscopic analysis of poly(ethylene terephthalate) on crystallization. Eur Polymer J 48:1586–1610

Chow YL, Chan CK, Kan CW (2011a) A study of physical modification on grey cotton by laser irradiation. Fibers Polym 12(2):275–280

Chow YL, Chan CK, Kan CW (2011b) Effect of CO2 laser treatment on cotton surface. Cellulose 18:1635–1641

Chow YL, Chan A, Kan CW (2012) Effect of CO2 laser irradiation on the properties of cotton fabric. Text Res J 82(12):1220–1234

CIE Technical Report (2004) Colorimetry. CIE Central Bureau, Vienna

Dascalu T, Acosta-Ortiz SE, Ortiz-Morles M, Compean I (2000) Removal of the indigo color by laser beam-denim interaction. Opt Lasers Eng 34(3):179–189

Ferrero F, Testore F, Tonin C, Innocenti R (2002) Surface degradation of linen textiles induced by laser treatment: comparison with electron beam and heat source. AUTEX Res J 2(3):109–114

Gandhi KL (2012) Woven textiles: principles, developments and applications. Woodhead Publishing, Cambridge

Ghoranneviss M, Shahidi S, Moazzenchi B, Anvari A, Rashidi A, Hosseini H (2007) Comparison between decolorization of denim fabrics with oxygen and argon glow discharge. Surf Coat Technol 201:4926–4930

Gotoh K, Hayashiya M (2008) Improvement of serviceability properties of synthetic textile fabrics using 172 nm ultraviolet excimer lamp. Text Res J 78(1):37–44

Gross JA, Herrmann RWT (2007) History of lasers. World J Urol 25:217–220

Hartzell-Lawson M, Hsieh YL (2000) Characterizing the noncellulosics in developing Cotton fibers. Text Res J 70(9):810–819

Hung ON, Song LJ, Chan CK, Kan CW, Yuen CWM (2011) Using artificial neural network to predict colour properties of laser-treated 100 % cotton fabric. Fibers Polym 12(8):1069–1076

Hung ON, Song LJ, Chan CK, Kan CW, Yuen CWM (2012) Laser-engraved color properties on cotton-Spandex fabric predicted by artificial neural network. AATCC Rev 12(3):57–63

Hung ON, Chan CK, Kan CW, Yuen CWM, Song LJ (2014) Artificial neural network approach for predicting color properties of laser treated denim fabrics. Fibers Polym 15(6):1330–1336

Hunt RWG (1998) Measuring colour. Fountain Press, England

Jolanta WG, Wolf K (2006) Damage caused to fibres by the action of two types of heat. Forensic Sci Int 159:119–126

Juciene M, Urbelis V, Juchneviciene Z, Cepukone L (2014) The effect of laser technological parameters on the color and structure of denim fabric. Text Res J 84(6):662–670

Kan CW (2014a) CO2 laser treatment as a clean process for treating denim fabric. J Clean Prod 66:624–631

Kan CW (2014b) Colour fading effect of indigo-dyed cotton denim fabric by CO2 laser. Fibers Polym 15(2):426–429

Kan CW, Yuen CWM, Cheng CW (2010) A technical study of the effect of CO2 laser surface engraving on some colour properties of denim fabric. Color Technol 126:365–371

Khajavi R, Novinrad B, Kiumarsi A (2007) The effect of ultrasonic on the denim fabric worn out process. J Biol Sci 10(4):645–648

Knittel D, Schollmeyer E (1998) Surface structuring of synthetic fibres by UV laser irradiation. Part 3: surface functionality changes resulting from excimer-laser irradiation. Polym Int 45:103–109

Knittel D, Kesting W, Schollmeyer E (1997) Surface structuring of synthetic fibres by UV laser irradiation. Part 2: mechanism and models. Polym Int 43:240–250

Ondogan Z, Pamuk O, Ondogan EN, Ozgney A (2005) Improving the appearance of all textile products from clothing to home textile using laser technology. Opt Laser Technol 37:631–637

Ozguney AT (2007) The comparison of laser surface designing and pigment printing methods for the product quality. Opt Laser Technol 39(5):1054–1058

Pfleging W, Adamietz R, Brückner HJ, Bruns M, Welle A (2007) Laser-assisted modification of polymers for microfluidic, micro-optics, and cell culture applications. Proc SPIE 6459:7–22

Stepankova M, Wiener J, Rusinova K (2011) Decolourization of vat dyes on cotton fabric with infrared laser light. Cellulose 18:469–478

Strlic M, Kolar J, Marincek M (2002) Surface modification during Nd:YAG (1064 nm) pulsed laser cleaning of organic fibrous materials. Appl Surf Sci 207:236–245

Strobel M, Walzak MJ, Hill JM, Lin A, Karbashewski Lyons CS (1995) A comparison of gas-phase methods of modifying polymer surfaces. J Adhes Sci Technol 9:365–383

Tarhan M, Sariisik M (2009) A comparison among performance characteristics of various denim fading processes. Text Res J 79(4):301–309

Teli MD, Khare AR, Chakrabati R (2008) Dependence of yarn and fabric strength on the structural parameters. AUTEX Res J 8(3):63–67

Wang X, Shen X, Xu W (2012) Effect of hydrogen peroxide treatment on the properties of wool fabric. Appl Surf Sci 258:10012–10016

Wong W, Chan K, Yeung KW, Lau KS (2001) Chemical surface modification of poly(ethylene terephthalate) by excimer irradiation of high and low intensities. Mater Res Innov 4(5–6):344–349

Yip J, Chan K, Sin KM, Lau KS (2004) Comprehensive study of polymer fiber surface modifications Part 1: high fluence UV-excimer-laser-induced structures. Polym Int 53:627–633

Yuan GX, Jiang SX, Newton E, Fan JT, Au WM (2011) Fashion design using laser engraving technology. 8ISS symposium panel on transformation, pp 65–69

Acknowledgments

Authors appreciate the financial support from The Hong Kong Polytechnic University for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hung, O.N., Chan, C.K., Kan, C.W. et al. An analysis of some physical and chemical properties of CO2 laser-treated cotton-based fabrics. Cellulose 24, 363–381 (2017). https://doi.org/10.1007/s10570-016-1090-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-1090-z