Abstract

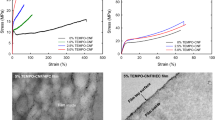

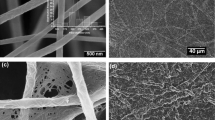

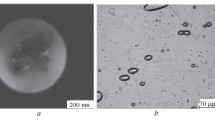

All-cellulose composites were produced by partial dissolution of two cellulosic sources in a mixture of sodium hydroxide and urea at low temperature. Filter paper (FP) and microfibrillated cellulose (MFC) were used to examine the role of the fiber dimensions of the initial reinforcing network on the final mechanical properties of thin self-reinforced all-cellulose composites. The dissolution time was used to control the extent of the transformation. The initial fiber structure was progressively transformed into a thoroughly consolidated composite material. X-ray diffraction and Fourier-transform infrared spectroscopy were able to show that the initial cellulose I allomorph was replaced with a cellulose II allomorph. FP underwent a fast crystallinity loss and transformation to cellulose II. In contrast, the crystallinity of MFC decreased slowly after dissolution. This result was also correlated with a slower allomorphic transformation. The crystallinity of MFC decreased to a level comparable to that of FP after 40 min and it remained comparatively unaffected at extended dissolution times. Comparison between powder and transmission XRD measurements demonstrated that the cellulose II present in all films after dissolution was strongly textured with its (1\(\bar{1}\)0) plane lying parallel to the sample surface despite fibrous microstructural features remaining from the initial substrates. The tensile strength and elastic modulus of FP increased significantly (+690 and +528 %, respectively) after only 20 min, while that of MFC remained relatively unaltered as a function of the dissolution time.

Similar content being viewed by others

References

Bellesia G, Gnanakaran S (2013) Sodium chloride interaction with solvated and crystalline cellulose: sodium ion affects the cellotetraose molecule and the cellulose fibril in aqueous solution. Cellulose 20:2695–2702. doi:10.1007/s10570-013-0063-8

Bonarski JT, Olek W (2010) Application of the crystalline volume fraction for characterizing the ultrastructural organization of wood. Cellulose 18:223–235. doi:10.1007/s10570-010-9486-7

Bras J (2004) Etudes des propriétés barrières de dérivés cellulosiques: application au gel de cellulose du papier sulfurisé. INPT, Toulouse

Buleon A, Chanzy H (1978) Single crystals of cellulose II. J Polym Sci Polym Phys Ed 16:833–839. doi:10.1002/pol.1978.180160508

Buleon A, Chanzy H, Roche E (1976) Epitaxial crystallization of cellulose II on valonia cellulose. J Polym Sci Polym Phys Ed 14:1913–1916. doi:10.1002/pol.1976.180141016

Buleon A, Chanzy H, Roche E (1977) Shish kebab-like structures of cellulose. J Polym Sci Polym Lett Ed 15:265–270. doi:10.1002/pol.1977.130150502

Cai J, Zhang L (2005) Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions. Macromol Biosci 5:539–548

Cai J, Liu Y, Zhang L (2006) Dilute solution properties of cellulose in LiOH/urea aqueous system. J Polym Sci, Part B: Polym Phys 44:3093

Cai J, Zhang L, Zhou J et al (2007) Multifilament fibers based on dissolution of cellulose in NaOH/urea aqueous solution: structure and properties. Adv Mater 19:821–825

Carillo F, Colom X, Suñol JJ, Saurina J (2004) Structural FTIR analysis and thermal characterisation of lyocell and viscose-type fibres. Eur Polym J 40:2229–2234

Cartier N, Escaffre P, Mathevet F et al (1994) Structure and recycling of vegetable parchment. Tappi J 77:95–100

Cross CF, Bevan EJ, Beadle C (1902) Treatment of viscose for the preparation of useful products therefrom, GB190103592 (A). Issued 9 Jan 1902. http://worldwide.espacenet.com/publicationDetails/biblio?FT=D&date=19020109&DB=EPODOC&locale=en_EP&CC=GB&NR=190103592A&KC=A&ND=4

de Gennes P-G (1979) Scaling concepts in polymer physics. Cornell University Press, Ithaca

Dinand E, Vignon M, Chanzy H, Heux L (2002) Mercerization of primary wall cellulose and its implication for the conversion of cellulose I → cellulose II. Cellulose 9:7–18. doi:10.1023/A:1015877021688

Duchemin B (2008) Structure, property and processing relationships of all-cellulose composites. Ph.D. thesis, University of Canterbury

Duchemin BJC (2015) Mercerisation of cellulose in aqueous NaOH at low concentrations. Green Chem 17:3941–3947. doi:10.1039/C5GC00563A

Duchemin B, Newman R, Staiger M (2007) Phase transformations in microcrystalline cellulose due to partial dissolution. Cellulose 14:311–320

Duchemin BJC, Mathew AP, Oksman K (2009a) All-cellulose composites by partial dissolution in the ionic liquid 1-butyl-3-methylimidazolium chloride. Compos Part Appl Sci Manuf 40:2031–2037. doi:10.1016/j.compositesa.2009.09.013

Duchemin BJC, Newman RH, Staiger MP (2009b) Structure-property relationship of all-cellulose composites. Compos Sci Technol 69:1225–1230

Duchemin B, Thuault A, Vicente A et al (2012) Ultrastructure of cellulose crystallites in flax textile fibres. Cellulose 19:1837–1854. doi:10.1007/s10570-012-9786-1

Egal M (2006) Structure and properties of cellulose/NaOH aqueous solutions, gels and regenerated objects. Ecole des mines de Paris

Egal M, Budtova T, Navard P (2008) The dissolution of microcrystalline cellulose in sodium hydroxide-urea aqueous solutions. Cellulose 15:361–370. doi:10.1007/s10570-007-9185-1

Fendt S, Padmanabhan S, Blanch HW, Prausnitz JM (2011) Viscosities of acetate or chloride-based ionic liquids and some of their mixtures with water or other common solvents. J Chem Eng Data 56:31–34. doi:10.1021/je1007235

Fink H-P, Weigel P, Purz HJ, Bohn A (1998) Structural aspects of new cellulose fibres and films from NMMO-solution. Recent Res Polym Sci 2:387–403

Fink H-P, Weigel P, Purz HJ, Ganster J (2001) Structure formation of regenerated cellulose materials from NMMO-solutions. Prog Polym Sci 26:1473–1524

Fink H-P, Ganster J, Lehmann A (2014) Progress in cellulose shaping: 20 years industrial case studies at Fraunhofer IAP. Cellulose 21:31–51. doi:10.1007/s10570-013-0137-7

Flandin L, Cavaillé JY, Bidan G, Brechet Y (2000) New nanocomposite materials made of an insulating matrix and conducting fillers: processing and properties. Polym Compos 21:165–174. doi:10.1002/pc.10174

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. doi:10.1007/s10570-013-0030-4

Gjønnes J, Norman N (1958) The use of half width and position of the lines in the x-ray diffractograms of native cellulose to characterize the structural properties of the samples. Acta Chem Scand 12:2028–2033

Gjønnes J, Norman N (1960) X-ray investigations on cellulose II and mixtures of cellulose I and II. 2. Lateral order in cellulose II. Acta Chem Scand 14:689–691

Glasser W, Atalla R, Blackwell J et al (2012) About the structure of cellulose: debating the Lindman hypothesis. Cellulose 19:589–598. doi:10.1007/s10570-012-9691-7

Han J, Zhou C, French AD et al (2013) Characterization of cellulose II nanoparticles regenerated from 1-butyl-3-methylimidazolium chloride. Carbohydr Polym 94:773–781. doi:10.1016/j.carbpol.2013.02.003

Hindeleh AM (1980) X-ray characterization of viscose rayon and the significance of crystallinity on tensile properties. Text Res J 50:581–589. doi:10.1177/004051758005001001

Hinterstoisser B, Salmen L (2000) Application of dynamic 2D FTIR to cellulose. Vib Spectrosc 22:111–118

Huber T, Müssig J, Curnow O et al (2012) A critical review of all-cellulose composites. J Mater Sci 47:1171–1186. doi:10.1007/s10853-011-5774-3

Huber T, Bickerton S, Müssig J et al (2013) Flexural and impact properties of all-cellulose composite laminates. Compos Sci Technol 88:92–98. doi:10.1016/j.compscitech.2013.08.040

Isogai A (1989) Solid-state CP/MAS 13C NMR study of cellulose polymorphs. Macromolecules 22:3168–3172

Isogai A, Atalla RH (1998) Dissolution of cellulose in aqueous NaOH solutions. Cellulose 5:309–319

Kalka S, Huber T, Steinberg J et al (2014) Biodegradability of all-cellulose composite laminates. Compos Part Appl Sci Manuf 59:37–44. doi:10.1016/j.compositesa.2013.12.012

Kamide K (2005) Characterization of molecular structure of cellulose derivatives. In: Cellulose and cellulose derivatives. Elsevier, Amsterdam, pp 25–188. http://www.sciencedirect.com/science/article/pii/B9780444822543500047

Kondo T, Sawatari C (1996) A fourier transform infra-red spectroscopic analysis of the character of hydrogen bonds in amorphous cellulose. Polymer 37:393–399

Laszkiewicz B (1998) Solubility of bacterial cellulose and its structural properties. J Appl Polym Sci 67:1871–1876

Lee CM, Mittal A, Barnette AL et al (2013) Cellulose polymorphism study with sum-frequency-generation (SFG) vibration spectroscopy: identification of exocyclic CH2OH conformation and chain orientation. Cellulose 20:991–1000. doi:10.1007/s10570-013-9917-3

Lourdin D, Peixinho J, Bréard J et al (2015) Concentration driven cocrystallisation and percolation in all-cellulose nanocomposites. Cellulose. doi:10.1007/s10570-015-0805-x

Lue A, Zhang L (2009) Rheological behaviors in the regimes from dilute to concentrated in cellulose solutions dissolved at low temperature. Macromol Biosci 9:488–496. doi:10.1002/mabi.200800231

Luo X, Zhang L (2010) Creation of regenerated cellulose microspheres with diameter ranging from micron to millimeter for chromatography applications. J Chromatogr A 1217:5922–5929. doi:10.1016/j.chroma.2010.07.026

Macrae CF, Bruno IJ, Chisholm JA et al (2008) Mercury CSD 2.0–new features for the visualization and investigation of crystal structures. J Appl Crystallogr 41:466–470

Marechal Y, Chanzy H (2000) The hydrogen bond network in Iβ cellulose as observed by infrared spectrometry. J Mol Struct 523:183–196

Marrinan HJ, Mann J (1956) Infrared spectra of the crystalline modifications of cellulose. J Polym Sci 21:301–311. doi:10.1002/pol.1956.120219812

Medronho B, Lindman B (2014) Competing forces during cellulose dissolution: from solvents to mechanisms. Curr Opin Colloid Interface Sci 19:32–40. doi:10.1016/j.cocis.2013.12.001

Murdock CC (1930) The form of the X-ray diffraction bands for regular crystals of colloidal size. Phys Rev 35:8–23

Nam S, French AD, Condon BD, Concha M (2016) Segal crystallinity index revisited by the simulation of X-ray diffraction patterns of cotton cellulose Iβ and cellulose II. Carbohydr Polym 135:1–9. doi:10.1016/j.carbpol.2015.08.035

Nelson ML, O’Connor RT (1964a) Relation of certain infrared bands to cellulose crystallinity and crystal lattice types. Part II. A new infrared ratio for estimation of crystallinity in celluloses I and II. J Appl Polym Sci 8:1325–1341

Nelson ML, O’Connor RT (1964b) Relation of certain infrared bands to cellulose crystallinity and crystal lattice types. Part I. Spectra of lattice types I, II, III and of amorphous cellulose. J Appl Polym Sci 8:1311–1324

Newman RH (2004) Carbon-13 NMR evidence for cocrystallization of cellulose as a mechanism for hornification of bleached kraft pulp. Cellulose 11:45–52. doi:10.1023/B:CELL.0000014768.28924.0c

Nishino T, Matsuda I, Hirao K (2004) All-cellulose composite. Macromolecules 37:7683–7687

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Ibeta from synchrotron X-ray and neutron fibre diffraction. J Am Chem Soc 124:9074–9082

O’Connor RT, DuPré EF, Mitcham D (1958) Applications of infrared absorption spectroscopy to investigations of cotton and modified cottons. Text Res J 28:382–392. doi:10.1177/004051755802800503

Oh SY, Yoo DI, Shin Y et al (2005) Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr Res 340:2376–2391

Okano T, Sarko A (1985) Mercerization of cellulose. II. Alkali–cellulose intermediates and a possible mercerization mechanism. J Appl Polym Sci 30:325–332. doi:10.1002/app.1985.070300128

Ouajai S, Shanks RA (2009) Preparation, structure and mechanical properties of all-hemp cellulose biocomposites. Compos Sci Technol 69:2119–2126. doi:10.1016/j.compscitech.2009.05.005

Pullawan T, Wilkinson AN, Eichhorn SJ (2010) Discrimination of matrix–fibre interactions in all-cellulose nanocomposites. Compos Sci Technol 70:2325–2330. doi:10.1016/j.compscitech.2010.09.013

Pullawan T, Wilkinson AN, Zhang LN, Eichhorn SJ (2014) Deformation micromechanics of all-cellulose nanocomposites: comparing matrix and reinforcing components. Carbohydr Polym 100:31–39. doi:10.1016/j.carbpol.2012.12.066

Qi H, Chang C, Zhang L (2008) Effects of temperature and molecular weight on dissolution of cellulose in NaOH/urea aqueous solution. Cellulose 15:779–787

Qi H, Cai J, Zhang L, Kuga S (2009) Properties of films composed of cellulose nanowhiskers and a cellulose matrix regenerated from alkali/urea solution. Biomacromolecules 10:1597–1602. doi:10.1021/bm9001975

Qin X, Lu A, Cai J, Zhang L (2013) Stability of inclusion complex formed by cellulose in NaOH/urea aqueous solution at low temperature. Carbohydr Polym 92:1315–1320. doi:10.1016/j.carbpol.2012.10.004

Schwanninger M, Rodrigues JC, Pereira H, Hinterstoisser B (2004) Effects of short-time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib Spectrosc 36:23–40

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Sobue H, Kiessig H, Hess K (1939) Das system cellulose-natriumhydroxyd-wasser in ahhängigkeit von der temperature. Ztg Phys Chem B43:309–328

Soykeabkaew N, Sian C, Gea S et al (2009) All-cellulose nanocomposites by surface selective dissolution of bacterial. Cellulose 16:435–444. doi:10.1007/s10570-009-9285-1

Tischer PCSF, Sierakowski MR, Westfahl H, Tischer CA (2010) Nanostructural reorganization of bacterial cellulose by ultrasonic treatment. Biomacromolecules 11:1217–1224. doi:10.1021/bm901383a

Wang Y, Chen L (2010) Impacts of nanowhisker on formation kinetics and properties of all-cellulose composite gels. Carbohydr Polym 83:1937–1946. doi:10.1016/j.carbpol.2010.10.071

Warwicker JO, Wright AC (1967) Function of sheets of cellulose chains in swelling reactions on cellulose. J Appl Polym Sci 11:659–671. doi:10.1002/app.1967.070110504

Wojdyr M (2010) Fityk: a general-purpose peak fitting program. J Appl Crystallogr 43:1126–1128. doi:10.1107/S0021889810030499

Xiong B, Zhao P, Cai P et al (2013) NMR spectroscopic studies on the mechanism of cellulose dissolution in alkali solutions. Cellulose 20:613–621. doi:10.1007/s10570-013-9869-7

Yamashiki T, Matsui T, Saitoh M et al (1990) Characterisation of cellulose treated by the steam explosion method. Part 2: effect of treatment conditions on changes in morphology, degree of polymerisation, solubility in aqueous sodium hydroxide and supermolecular structure of soft wood pulp during steam explosion. Br Polym J 22:121–128

Yang Q, Lue A, Zhang L (2010) Reinforcement of ramie fibers on regenerated cellulose films. Compos Sci Technol 70:2319–2324. doi:10.1016/j.compscitech.2010.09.012

Yue Y, Zhou C, French AD et al (2012) Comparative properties of cellulose nano-crystals from native and mercerized cotton fibers. Cellulose 19:1173–1187. doi:10.1007/s10570-012-9714-4

Yue Y, Han J, Han G et al (2015) Characterization of cellulose I/II hybrid fibers isolated from energycane bagasse during the delignification process: morphology, crystallinity and percentage estimation. Carbohydr Polym 133:438–447. doi:10.1016/j.carbpol.2015.07.058

Zhang L (2001) Structure and properties of regenerated cellulose films prepared from cotton linters in NaOH/urea aqueous solution. Ind Eng Chem Res 40:5923

Zhang S, Li F-X, Yu J-Y (2011) Rheological properties of cellulose-NaOH complex solutions: from dilute to concentrated states. Cellul Chem Technol 45:313

Zhao J, He X, Wang Y et al (2014) Reinforcement of all-cellulose nanocomposite films using native cellulose nanofibrils. Carbohydr Polym 104:143–150. doi:10.1016/j.carbpol.2014.01.007

Zhou J, Zhang L, Cai J (2004) Behavior of cellulose in NaOH/Urea aqueous solution characterized by light scattering and viscometry. J Polym Sci, Part B: Polym Phys 42:347–353

Acknowledgments

The authors would like to thank the Royal Society of New Zealand and Campus France for their support through the Dumont D’Urville funding program (Project 25787TE). The authors are gratefully acknowledge assistance from Mr. Mike Flaws (UC) with SEM, Mr. Kevin Stobbs (UC) with tensile testing, and Ms. Céline Picard (ULH) with FTIR. The authors would also like to thank Dr. Alfred French (ARS, USDA) for his constructive comments on the manuscript and for his suggestions regarding the XRD interpretations.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Duchemin, B., Le Corre, D., Leray, N. et al. All-cellulose composites based on microfibrillated cellulose and filter paper via a NaOH-urea solvent system. Cellulose 23, 593–609 (2016). https://doi.org/10.1007/s10570-015-0835-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0835-4