Abstract

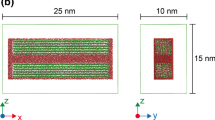

The mechanical properties of Iβ crystalline cellulose are studied using molecular dynamics simulation. A model Iβ crystal is deformed in the three orthogonal directions at three different strain rates. The stress–strain behaviors for each case are analyzed and then used to calculate mechanical properties. The results show that the elastic modulus, Poisson’s ratio, yield stress and strain, and ultimate stress and strain are highly anisotropic. In addition, while the properties that describe the elastic behavior of the material are independent of strain rate, the yield and ultimate properties increase with increasing strain rate. The deformation and failure modes associated with these properties and the relationships between the material’s response to tension and the evolution of the crystal structure are analyzed.

Similar content being viewed by others

References

Bergenstråhle M, Berglund LA, Mazeau K (2007) Thermal response in crystalline Iβ cellulose: a molecular dynamics study. J Phys Chem B 111(30):9138–9145

Cao BY, Li YW, Kong J, Chen H, Xu Y, Yung KL, Cai A (2011) High thermal conductivity of polyethylene nanowire arrays fabricated by an improved nanoporous template wetting technique. Polymer 52(8):1711–1715

Diddens I, Murphy B, Krisch M, Muller M (2008) Anisotropic elastic properties of cellulose measured using inelastic X-ray scattering. Macromolecules 41(24):9755–9759

Dri FL, Hector LG, Moon RJ, Zavattieri PD (2013) Anisotropy of the elastic properties of crystalline cellulose Iβ from first principles density functional theory with Van der Waals interactions. Cellulose 20(6):2703–2718

Eichhorn S, Davies G (2006) Modelling the crystalline deformation of native and regenerated cellulose. Cellulose 13(3):291–307

Eichhorn SJ (2011) Cellulose nanowhiskers: promising materials for advanced applications. Soft Matter 7(2):303–315

Hossain D, Tschopp M, Ward D, Bouvard J, Wang P, Horstemeyer M (2010) Molecular dynamics simulations of deformation mechanisms of amorphous polyethylene. Polymer 51(25):6071–6083

Iwamoto S, Kai W, Isogai A, Iwata T (2009) Elastic modulus of single cellulose microfibrils from tunicate measured by atomic force microscopy. Biomacromolecules 10(9):2571–2576

Koh ASJ, Lee HP (2006) Shock-induced localized amorphization in metallic nanorods with strain-rate-dependent characteristics. Nano Lett 6(10):2260–2267

Koh S, Lee H, Lu C, Cheng Q (2005) Molecular dynamics simulation of a solid platinum nanowire under uniaxial tensile strain: temperature and strain-rate effects. Phys Rev B 72(8):085414

Lahiji RR, Xu X, Reifenberger R, Raman A, Rudie A, Moon RJ (2010) Atomic force microscopy characterization of cellulose nanocrystals. Langmuir 26(6):4480–4488

Liang T, Shin YK, Cheng YT, Yilmaz DE, Vishnu KG, Verners O, Zou C, Phillpot SR, Sinnott SB, van Duin AC (2013) Reactive potentials for advanced atomistic simulations. Annu Rev Mater Res 40(3):109–129

Liang W, Zhou M (2004) Response of copper nanowires in dynamic tensile deformation. Proc Inst Mech Eng Part C 218(6):599–606

Liew K, He X, Wong C (2004) On the study of elastic and plastic properties of multi-walled carbon nanotubes under axial tension using molecular dynamics simulation. Acta Mater 52(9):2521–2527

Lin N, Huang J, Dufresne A (2012) Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials: a review. Nanoscale 4(11):3274–3294

Lu P, Hsieh YL (2009) Cellulose nanocrystal-filled poly(acrylic acid) nanocomposite fibrous membranes. Nanotechnology 20(41):415604

Mark RE (1968) Cell wall mechanics of tracheids. Yale University Press, New Haven

Mattsson TR, Lane JMD, Cochrane KR, Desjarlais MP, Thompson AP, Pierce F, Grest GS (2010) First-principles and classical molecular dynamics simulation of shocked polymers. Phys Rev B 81(5):054103

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40(7):3941–3994

Nakamura K, Wada M, Kuga S, Okano T (2004) Poisson’s ratio of cellulose Iβ and cellulose II. J Polym Sci Part B Polym Phys 42(7):1206–1211

Neyertz S, Pizzi A, Merlin A, Maigret B, Brown D, Deglise X (2000) A new all-atom force field for crystalline cellulose I. J Appl Polym Sci 78(11):1939–1946

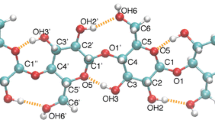

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124(31):9074–9082

Pakzad A, Simonsen J, Pa Heiden, Yassar RS (2011) Size effects on the nanomechanical properties of cellulose I nanocrystals. J Mater Res 27(03):528–536

Pei A, Malho JM, Ruokolainen J, Zhou Q, Berglund LA (2011) Strong nanocomposite reinforcement effects in polyurethane elastomer with low volume fraction of cellulose nanocrystals. Macromolecules 44(11):4422–4427

Ramesh K (2008) Handbook of experimental solid mechanics. Springer, New York

Reiling S, Brickmann J (1995) Theoretical investigations on the structure and physical properties of cellulose. Macromol Theory Simul 4(4):725–743

Rusli R, Eichhorn SJ (2008) Determination of the stiffness of cellulose nanowhiskers and the fiber-matrix interface in a nanocomposite using Raman spectroscopy. Appl Phys Lett 93(3):033111

Saito T, Kuramae R, Wohlert J, Berglund LA, Isogai A (2013) An ultrastrong nanofibrillar biomaterial: the strength of single cellulose nanofibrils revealed via sonication-induced fragmentation. Biomacromolecules 14(1):248–253

Siqueira G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 10(2):425–432

Sturcová A, Davies GR, Eichhorn SJ (2005) Elastic modulus and stress–transfer properties of tunicate cellulose whiskers. Biomacromolecules 6(2):1055–1061

Tan E, Lim C (2006) Mechanical characterization of nanofibers-a review. Compos Sci Technol 66(9):1102–1111

Tanaka F, Iwata T (2006) Estimation of the elastic modulus of cellulose crystal by molecular mechanics simulation. Cellulose 13(5):509–517

Tomar V, Zhou M (2007) Analyses of tensile deformation of nanocrystalline α-Fe2O3+fcc-Al composites using molecular dynamics simulations. J Mech Phys Solids 55(5):1053–1085

Wagner R, Moon R, Pratt J, Shaw G, Raman A (2011) Uncertainty quantification in nanomechanical measurements using the atomic force microscope. Nanotechnology 22(45):455703

Wei C, Cho K, Srivastava D (2003) Tensile strength of carbon nanotubes under realistic temperature and strain rate. Phys Rev B 67(11):115407

Wohlert J, Bergenstråhle-Wohlert M, Berglund LA (2012) Deformation of cellulose nanocrystals: entropy, internal energy and temperature dependence. Cellulose 19(6):1821–1836

Wu HA (2006) Molecular dynamics study of the mechanics of metal nanowires at finite temperature. Eur J Mech A-Solid 25(2):370–377

Wu X, Moon RJ, Martini A (2013) Crystalline cellulose elastic modulus predicted by atomistic models of uniform deformation and nanoscale indentation. Cellulose 20(1):43–55

Xu X, Liu F, Jiang L, Zhu JY, Haagenson D, Wiesenborn DP (2013) Cellulose nanocrystals vs. cellulose nanofibrils: a comparative study on their microstructures and effects as polymer reinforcing agents. ACS Appl Mater Interfaces 5(8):2999–3009

Yamakov V, Wolf D, Phillpot SR, Mukherjee AK, Gleiter H (2004) Deformation-mechanism map for nanocrystalline metals by molecular-dynamics simulation. Nat Mater 3(1):43–47

Acknowledgments

The authors thank the Air Force Office of Sponsored Research Grant: FA9550–11–1–0162 for support of this research.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wu, X., Moon, R.J. & Martini, A. Tensile strength of Iβ crystalline cellulose predicted by molecular dynamics simulation. Cellulose 21, 2233–2245 (2014). https://doi.org/10.1007/s10570-014-0325-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0325-0