Abstract

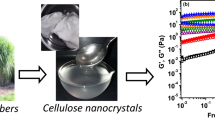

Bio-based continuous fibers were prepared by melt spinning cellulose acetate butyrate (CAB), cellulose nanocrystals (CNC) and triethyl citrate. A CNC organo-gel dispersion technique was used and the prepared materials (2 and 10 wt% CNC) were melt spun using a twin-screw micro-compounder and drawn to a ratio of 1.5. The microscopy studies showed that the addition of CNC in CAB resulted in defect-free and smooth fiber surfaces. An addition of 10 wt% CNC enhanced the storage modulus and increased the tensile strength and Young’s modulus. Fiber drawing improved the mechanical properties further. In addition, a micromechanical model of the composite material was used to estimate the stiffness and showed that theoretical values were exceeded for the lower concentration of CNC but not reached for the higher concentration. In conclusion, this dispersion technique combined with melt spinning can be used to produce all-cellulose nanocomposites fibers and that both the increase in CNC volume fraction and the fiber drawing increased the mechanical performance.

Similar content being viewed by others

References

Andersons J, Spārniņš E, Joffe R (2006) Stiffness and strength of flax fiber/polymer matrix composites. Polym Compos 27:221–229. doi:10.1002/pc.20184

Ayuk JE, Mathew AP, Oksman K (2009) The effect of plasticizer and cellulose nanowhisker content on the dispersion and properties of cellulose acetate butyrate nanocomposites. J Appl Polym Sci 114:2723–2730. doi:10.1002/app.30583

Azizi Samir MAS, Alloin F, Sanchez J, El Kissi N, Dufresne A (2004) Preparation of cellulose whiskers reinforced nanocomposites from an organic medium suspension. Macromolecules 37:1386–1393. doi:10.1021/ma030532a

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6:612–626. doi:10.1021/bm0493685

Bondeson D, Oksman K (2007) Dispersion and characteristics of surfactant modified cellulose whiskers nanocomposites. Compos Interfaces 14:617–630. doi:10.1163/156855407782106519

Bondeson D, Syre P, Oksman Niska K (2007) All cellulose nanocomposites produced by extrusion. J Biobased Mater Bioenergy 1:367–371. doi:10.1166/jbmb.2007.011

Capadona JR, Van Den Berg O, Capadona LA, Schroeter M, Rowan SJ, Tyler DJ, Weder C (2007) A versatile approach for the processing of polymer nanocomposites with self-assembled nanofibre templates. Nat Nanotechnol 2:765–769. doi:10.1038/nnano.2007.379

Capadona JR, Shanmuganathan K, Tyler DJ, Rowan SJ, Weder C (2008) Stimuli-responsive polymer nanocomposites inspired by the sea cucumber dermis. Science 319:1370–1374. doi:10.1126/science.1153307

Capadona JR, Shanmuganathan K, Trittschuh S, Seidel S, Rowan SJ, Weder C (2009) Polymer nanocomposites with nanowhiskers isolated from microcrystalline cellulose. Biomacromolecules 10:712–716. doi:10.1021/bm8010903

Fornes TD, Baur JW, Sabba Y, Thomas EL (2006) Morphology and properties of melt-spun polycarbonate fibers containing single- and multi-wall carbon nanotubes. Polymer 47:1704–1714. doi:10.1016/j.polymer.2006.01.003

Grunert M, Winter W (2002) Nanocomposites of cellulose acetate butyrate reinforced with cellulose nanocrystals. J Polym Environ 10:27–30. doi:10.1023/A:1021065905986

Haggenmueller R, Gommans HH, Rinzler AG, Fischer JE, Winey KI (2000) Aligned single-wall carbon nanotubes in composites by melt processing methods. Chem Phys Lett 330:219–225. doi:10.1016/S0009-2614(00)01013-7

Herrera MA, Mathew AP, Oksman K (2012) Characterization of cellulose nanowhiskers: a comparison of two industrial bio-residues. IOP Conference Series: Mat Sci Eng 31:012006. doi:10.1088/1757-899X/31/1/012006

Hooshmand S, Soroudi A, Skrifvars M (2011) Electro-conductive composite fibers by melt spinning of polypropylene/polyamide/carbon nanotubes. Synth Met 161:1731–1737. doi:10.1016/j.synthmet.2011.06.014

Hooshmand S, Cho S, Skrifvars M, Mathew AP, Oksman K (2014) Melt spun cellulose nanocomposite fibres: comparison of two dispersion techniques. Plast Rubber Compos 43:15–24. doi:10.1179/1743289813Y.0000000066

John MJ, Anandjiwala R, Oksman K, Mathew AP (2013) Melt-spun polylactic acid fibers: effect of cellulose nanowhiskers on processing and properties. J Appl Polym Sci 127:274–281. doi:10.1002/app.37884

Kosaka PM, Kawano Y, Fantini MC, Petri DF (2006) Structure and properties of maleated linear low-density polyethylene and cellulose acetate butyrate blends. Macromol Mater Eng 291:531–539. doi:10.1002/mame.200500413

Lee SH, Youn JR (2008) Properties of polypropylene/layered-silicate nanocomposites and melt-spun fibers. J Appl Polym Sci 109:1221–1231. doi:10.1002/app.28222

Mazinani S, Ajji A, Dubois C (2010) Structure and properties of melt-spun PET/MWCNT nanocomposite fibers. Polym Eng Sci 50:1956–1968. doi:10.1002/pen.21727

O’Brien JP, Aneja AP (1999) Fibres for the next millennium. Rev Prog Coloration 29:1–7. doi:10.1111/j.1478-4408.1999.tb00122.x

Park H, Misra M, Drzal LT, Mohanty AK (2004) “Green” nanocomposites from cellulose acetate bioplastic and clay: effect of eco-friendly triethyl citrate plasticizer. Biomacromolecules 5:2281–2288. doi:10.1021/bm049690f

Petersson L, Mathew AP, Oksman K (2009) Dispersion and properties of cellulose nanowhiskers and layered silicates in cellulose acetate butyrate nanocomposites. J Appl Polym Sci 112:2001–2009. doi:10.1002/app.29661

Pötschke P, Brünig H, Janke A, Fischer D, Jehnichen D (2005) Orientation of multiwalled carbon nanotubes in composites with polycarbonate by melt spinning. Polymer 46:10355–10363. doi:10.1016/j.polymer.2005.07.106

Pötschke P, Andres T, Villmow T, Pegel S, Brünig H, Kobashi K, Fischer D, Häussler L (2010) Liquid sensing properties of fibres prepared by melt spinning from poly(lactic acid) containing multi-walled carbon nanotubes. Compos Sci Technol 70:343–349. doi:10.1016/j.compscitech.2009.11.005

Rodríguez M, Vila-Jato JL, Torres D (1998) Design of a new multiparticulate system for potential site-specific and controlled drug delivery to the colonic region. J Control Release 55:67–77. doi:10.1016/S0168-3659(98)00029-7

Sakurada I, Nukushina Y, Ito T (1962) Experimental determination of the elastic modulus of crystalline regions in oriented polymers. J Polym Sci 57:651–660. doi:10.1002/pol.1962.1205716551

Scaffaro R, Maio A, Tito AC (2012) High performance PA6/CNTs nanohybrid fibers prepared in the melt. Compos Sci Technol 72:1918–1923. doi:10.1016/j.compscitech.2012.08.010

Schadler LS (2004) Polymer-based and polymer-filled nanocomposites. 77–153. doi:10.1002/3527602127.ch2

Schroers M, Kokil A, Weder C (2004) Solid polymer electrolytes based on nanocomposites of ethylene oxide-epichlorohydrin copolymers and cellulose whiskers. J Appl Polym Sci 93:2883–2888. doi:10.1002/app.20870

Segal L, Conrad C (1957) Characterization of cellulose derivatives by means of the X-ray diffractometer. Am Dyest Rep 46:637–642

Segal L, Creely J, Martin A, Conrad C (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Siqueira G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 10:425–432. doi:10.1021/bm801193d

Siqueira G, Mathew AP, Oksman K (2011) Processing of cellulose nanowhiskers/cellulose acetate butyrate nanocomposites using sol–gel process to facilitate dispersion. Compos Sci Technol 71:1886–1892. doi:10.1016/j.compscitech.2011.09.002

Solarski S, Mahjoubi F, Ferreira M, Devaux E, Bachelet P, Bourbigot S, Delobel R, Coszach P, Murariu M, silva Ferreira A, Alexandre M, Degee P, Dubois P (2007) (Plasticized) polylactide/clay nanocomposite textile: thermal, mechanical, shrinkage and fire properties. J Mater Sci 42:5105–5117. doi:10.1007/s10853-006-0911-0

Solarski S, Ferreira M, Devaux E, Fontaine G, Bachelet P, Bourbigot S, Delobel R, Coszach P, Murariu M, Da Ferreira Silva A, Alexandre M, Degee P, Dubois P (2008) Designing polylactide/clay nanocomposites for textile applications: effect of processing conditions, spinning, and characterization. J Appl Polym Sci 109:841–851. doi:10.1002/app.28138

Van den Berg O, Schroeter M, Capadona JR, Weder C (2007) Nanocomposites based on cellulose whiskers and (semi) conducting conjugated polymers. J Mater Chem 17:2746–2753. doi:10.1039/B700878C

Watson BJ, Hammouda B, Briber RM, Hutcheson SW (2013) Influence of organic liquids on the nanostructure of precipitated cellulose. J Appl Polym Sci 127:2620–2627. doi:10.1002/app.37540

Yoon K, Polk MB, Min BG, Schiraldi DA (2004) Structure and property study of nylon-6/clay nanocomposite fiber. Polym Int 53:2072–2078. doi:10.1002/pi.1630

Acknowledgments

The authors gratefully acknowledge the Bio4Energy and VINNOVA for the financial support of this work as well as Domsjö Fabriker AB for the supplied materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hooshmand, S., Aitomäki, Y., Skrifvars, M. et al. All-cellulose nanocomposite fibers produced by melt spinning cellulose acetate butyrate and cellulose nanocrystals. Cellulose 21, 2665–2678 (2014). https://doi.org/10.1007/s10570-014-0269-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0269-4