Abstract

Pressure–volume–temperature (PVT) measurements of α-cellulose with different water contents, were performed at temperatures from 25 to 180 °C and pressures from 19.6 to 196 MPa. PVT measurements allowed observation of the combined effects of pressure and temperature on the specific volume during cellulose thermo-compression. All isobars showed a decrease in cellulose specific volume with temperature. This densification is associated with a transition process of the cellulose, occurring at a temperature defined by the inflection point T t of the isobar curve. T t decreases from 110 to 40 °C with pressure and is lower as moisture content increases. For isobars obtained at high pressures and high moisture contents, after attaining a minimum, an increase in volume is observed with temperature that may be related to free water evaporation. PVT α-cellulose experimental data was compared with predicted values from a regression analysis of the Tait equations of state, usually applied to synthetic polymers. Good correlations were observed at low temperatures and low pressures. The densification observed from the PVT experimental data, at a temperature that decreases with pressure, could result from a sintering phenomenon, but more research is needed to actually understand the cohesion mechanism under these conditions.

Similar content being viewed by others

References

Akande O, Rubinstein M, Rowe P, Ford J (1997) Effect of compression speeds on the compaction properties of a 1:1 paracetamol–microcrystalline cellulose mixture prepared by single compression and by combinations of pre-compression and main-compression. Int J Pharm 157(2):127–136

Avérous L (2004) Biodegradable multiphase systems based on plasticized starch: a review. J Macromol Sci C Polym Rev 44(3):231–274

Chang R, Chen C, Su K (1996) Modifying the tait equation with cooling-rate effects to predict the pressure–volume–temperature behaviors of amorphous polymers: modeling and experiments. Polym Eng Sci 36(13):1789–1795

Coble R (1958) Initial sintering of alumina and hematite. J Am Ceram Soc 41(2):55–62

Dee G, Walsh D (1988) Equations of state for polymer liquids. Macromolecules 21(3):811–815

Derraik J (2002) The pollution of the marine environment by plastic debris: a review. Mar Pollut Bull 44(9):842–852

Jain S (1999) Mechanical properties of powders for compaction and tableting: an overview. Pharm Sci Technol Today 2(1):20–31

Kumar V, Kothari S (1999) Effect of compressional force on the crystallinity of directly compressible cellulose excipients. Int J Pharm 177(2):173–182

Nanda V, Simha R (1964) Theoretical interpretation of tait equation parameters. J Chem Phys 41(6):1884–1885

Navard P (2012) Processing cellulose of elevated pressure, regenerated cellulose and cellulose derivatives, örnsköldsvik, sweden. In: Regenerated cellulose and cellulose derivatives, Örnsköldsvik, Sweden

Nilsson H, Galland S, Larsson P, Gamstedt E, Nishino T, Berglund L, Iversen T (2010) A non-solvent approach for high-stiffness all-cellulose biocomposites based on pure wood cellulose. Compos Sci Technol 70(12):1704–1712

Otaigbe J, Jane J (1997) Pressure-volume-temperature relationships of soy protein isolate/starch plastic. J Polym Environ 5(2):75–80

Patel S, Kaushal A, Bansal A (2006) Compression physics in the formulation development of tablets. Crit Rev Ther Drug Carrier Syst 23(1):1–66

Picker K (2003) The relevance of glass transition temperature for the process of tablet formation. J Therm Anal Calorim 73(2):597–605

Picker-Freyer K (2007) An insight into the process of tablet formation of microcrystalline cellulose. J Therm Anal Calorim 89(3):745–748

Pintiaux T, Viet D, Vandenbossche V, Rigal L, Rouilly A (2013) High pressure compression-molding of α-cellulose and effects of operating conditions. Materials 6(6):2240–2261

Quach A, Simha R (1971) Pressure-volume-temperature properties and transitions of amorphous polymers; polystyrene and poly (orthomethylstyrene). J Appl Phys 42(12):4592–4606

Rodgers P (1993) Pressure–volume–temperature relationships for polymeric liquids: a review of equations of state and their characteristic parameters for 56 polymers. J Appl Polym Sci 48(6):1061–1080

Rouilly A, Rigal L (2002) Agro-materials: a bibliographic review. J Macromol Sci C Polym Rev 42(4):441–479

Sato Y, Inohara K, Takishima S, Masuoka H, Imaizumi M, Yamamoto H, Takasugi M (2000) Pressure-volume-temperature behavior of polylactide, poly (butylene succinate), and poly (butylene succinate-co-adipate). Polym Eng Sci 40(12):2602–2609

Scott G (2000) Greenpolymers. Polym Degrad Stab 68(1):1–7

Simha R, Wilson P, Olabisi O (1973) Pressure-volume-temperature properties of amorphous polymers: empirical and theoretical predictions. Colloid Polym Sci 251(6):402–408

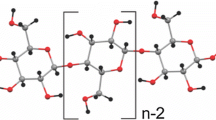

Simon I, Glasser L, Scheraga HA, Manley RJ (1988) Structure of cellulose. 2. low-energy crystalline arrangements. Macromolecules 21(4):990–998

Vaca-Medina G, Jallabert B, Viet D, Peydecastaing J, Rouilly A (Accepted) Effect of temperature on high pressure cellullose compression. Cellulose

Zhang X, Wu X, Gao D, Xia K (1988) Bulk cellulose plastic materials from processing cellulose powder using back pressure-equal channel angular pressing. Carbohydr Polym 87(4):2470–2476

Acknowledgments

The authors would like to thank The French National Research Agency (ANR) and the Competitive Cluster for the Agricultural and Food Industries in South-West France (AGRIMIP), for funding this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jallabert, B., Vaca-Medina, G., Cazalbou, S. et al. The pressure–volume–temperature relationship of cellulose. Cellulose 20, 2279–2289 (2013). https://doi.org/10.1007/s10570-013-9986-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-9986-3