Abstract

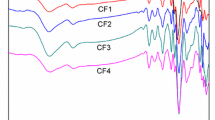

Highly intrinsic conductive polypyrrole/cellulose fiber composites (CF) were successfully prepared through in situ chemical oxidation polymerization simply by increasing fiber concentration at the same dosage of pyrrole, oxidant and dopant (based on the weight of dry fiber). FeCl3 and anthraquinone-2-sulfonic acid sodium salt (AQSNa) were utilized as oxidant and dopant. As fiber concentration increased from 1 % (CF1) to 20 % (CF20), N and S content increased from 0.24 and 0.25 % to 1.24 and 0.89 %, and great increase in the retention of PPy and AQSNa was confirmed by elemental analysis. In addition, on the surface of conductive fiber, PPy of compact fibroid structure was detected instead of interconnected globular structure at higher fiber concentration. Furthermore, scanning transmission electron microscope and X-ray photoelectron spectroscopy (XPS)-depth profile analysis demonstrated denser and more uniformly distributed PPy inside fiber wall for CF20, while PPy tended to deposit on the surface of fiber for CF1. Fourier transform infrared spectroscopy, together with XPS certified that the PPy with longer conjugation length and higher doping level across the conductive fiber was obtained at higher fiber concentration. The doping level for CF10 decreased from 21.55 to 16.39 % with increasing fiber wall thickness, while that of CF20 decreased slightly from 30.73 to 24.10 %. The resulting CF20 showed lowest surface resistivity of 0.433 KΩ/square, as well as improved electro-conductivity stability. The incorporation of more PPy in CF improved the thermal stability.

Similar content being viewed by others

References

Auad ML, Richardson T, Orts WJ, Medeiros ES, Mattoso LH, Mosiewicki MA, Marcovich NE, Aranguren MI (2011) Polyaniline-modified cellulose nanofibrils as reinforcement of a smart polyurethane. Polym Int 60(5):743–750. doi:10.1002/pi.3004

Beneventi D, Alila S, Boufi S, Chaussy D, Nortier P (2006) Polymerization of pyrrole on cellulose fibres using a FeCl3 impregnation-pyrrole polymerization sequence. Cellulose 13(6):725–734. doi:10.1007/s10570-006-9077-9

Boukerma K, Omastová M, Fedorko P, Chehimi MM (2005) Surface properties and conductivity of bis(2-ethylhexyl) sulfosuccinate-containing polypyrrole. Appl Surf Sci 249(1–4):303–314. doi:10.1016/j.apsusc.2004.12.011

Carrasco PM, Grande HJ, Cortazar M, Alberdi JM, Areizaga J, Pomposo JA (2006) Structure-conductivity relationships in chemical polypyrroles of low, medium and high conductivity. Synth Met 156(5–6):420–425. doi:10.1016/j.synthmet.2006.01.005

Carrasco PM, Cortazar M, Ochoteco E, Calahorra E, Pomposo JA (2007) Comparison of surface and bulk doping levels in chemical polypyrroles of low, medium and high conductivity. Surf Interface Anal 39(1):26–32. doi:10.1002/sia.2457

Chen Y, Qian X, An X (2011) Preparation and characterization of conductive paper via in situ polymerization of 3,4-ethylenedioxythiophene. BioResources 6(3):3410–3423

Ding C, Qian X, Shen J, An X (2010a) Preparation and characterization of conductive paper via in situ polymerization of pyrrole. BioResources 5(1):303–315

Ding C, Qian X, Yu G, An X (2010b) Dopant effect and characterization of polypyrrolecellulose composites prepared by in situ polymerization process. Cellulose 17(6):1067–1077. doi:10.1007/s10570-010-9442-6

Fatehi P, Xiao H (2010) Effect of cationic PVA characteristics on fiber and paper properties at saturation level of polymer adsorption. Carbohydr Polym 79(2):423–428. doi:10.1016/j.carbpol.2009.08.029

Ferrero F, Napoli L, Tonin C, Varesano A (2006) Pyrrole chemical polymerization on textiles: kinetics and operating conditions. J Appl Polym Sci 102(5):4121–4126. doi:10.1002/app.24149

Flores O, Romo-Uribe A, Romero-Guzmán ME, González AE, Cruz-Silva R, Campillo B (2009) Mechanical properties and fracture behavior of polypropylene reinforced with polyaniline-grafted short glass fibers. J Appl Polym Sci 112(2):934–941. doi:10.1002/app.29453

Granato F, Bianco A, Bertarelli C, Zerbi G (2009) Composite polyamide 6/polypyrrole conductive nanofibers. Macromol Rapid Commun 30(6):453–458. doi:10.1002/marc.200800623

Grunden B, Iroh JO (1995) Formation of graphite fibre-polypyrrole coatings by aqueous electrochemical polymerization. Polymer 36(3):559–563. doi:10.1016/0032-3861(95)91565-O

Hakansson E, Kaynak A, Lin T, Nahavandi S, Jones T, Hu E (2004) Characterization of conducting polymer coated synthetic fabrics for heat generation. Synth Met 144(1):21–28. doi:10.1016/j.synthmet.2004.01.003

Huang B, Kang G, Ni Y (2005) Electrically conductive fibre composites prepared from polypyrrole- engineered pulp fibres. Can J Chem Eng 83(5):896–903. doi:10.1002/cjce.5450830512

Huang B, Kang GJ, Ni Y (2006) Preparation of conductive paper by in situ polymerization of pyrrole in a pulp fibre system. Pulp & Paper Canada 107(2):38–42

Jahan MS, Rahman MM (2012) Effect of pre-hydrolysis on the soda-anthraquinone pulping of corn stalks and Saccharum spontaneum (kash). Carbohydr Polym 88(2):583–588. doi:10.1016/j.carbpol.2012.01.005

Kang ET, Neoh KG, Ong YK, Tan KL, Tan BTG (1991) X-ray photoelectron spectroscopic studies of polypyrrole synthesized with oxidative iron (III) state. Macromolecules 24(10):2822–2828. doi:10.1021/ma00010a028

Lei J, Cai Z, Martin CR (1992) Effect of reagent concentrations used to synthesize polypyrrole on the chemical characteristics and optical and electronic properties of the resulting polymer. Synth Met 46(1):53–69. doi:10.1016/0379-6779(92)90318-D

Li Y, Cheng XY, Leung MY, Tsang J, Tao XM, Yuen MCW (2005) A flexible strain sensor from polypyrrole-coated fabrics. Synth Met 155(1):89–94. doi:10.1016/j.synthmet.2005.06.008

Li J, Qian XR, Chen JH, Ding CY, An XH (2010) Conductivity decay of cellulosepolypyrrole conductive paper composite prepared by in situ polymerization method. Carbohydr Polym 82(2):504–509. doi:10.1016/j.carbpol.2010.05.036

Lin YC, Cho J, Tompsett GA, Westmoreland PR, Huber GW (2009) Kinetics and mechanism of cellulose pyrolysis. J Phys Chem C 113(46):20097–20107. doi:10.1021/jp906702p

Madani A, Nessark B, Brayner R, Elaissari H, Jouini M, Mangeney C, Chehimi MM (2010) Carboxylic acid-functionalized, core-shell polystyrene@polypyrrole microspheres as platforms for the attachment of CdS nanoparticles. Polymer 51(13):2825–2835. doi:10.1016/j.polymer.2010.04.020

McCullough LA, Dufour B, Matyjaszewski K (2009) Polyaniline and polypyrrole templated on self-assembled acidic block copolymers. Macromolecules 42(21):8129–8137. doi:10.1021/ma901560k

Menon VP, Lei J, Martin CR (1996) Investigation of molecular and supermolecular structure in template-synthesized polypyrrole tubules and fibrils. Chem Mater 8(9):2382–2390. doi:10.1021/cm960203f

Molina J, del Río AI, Bonastre J, Cases F (2009) Electrochemical polymerisation of aniline on conducting textiles of polyester covered with polypyrrole/AQSA. Eur Polym J 45(4):1302–1315. doi:10.1016/j.eurpolymj.2008.11.003

Nair S, Natarajan S, Kim SH (2005) Fabrication of electrically conducting polypyrrolepoly(ethylene oxide) composite nanofibers. Macromol Rapid Commun 26(20):1599–1603. doi:10.1002/marc.200500457

Nair S, Hsiao E, Kim SH (2008) Fabrication of electrically-conducting nonwoven porous mats of polystyrene-polypyrrole core-shell nanofibers via electrospinning and vapor phase polymerization. J Mater Chem 18(42):5155–5161. doi:10.1039/B807007E

Nyström G, Razaq A, Strømme M, Nyholm L, Mihranyan A (2009) Ultrafast allpolymer paper-based batteries. Nano Lett 9(10):3635–3639. doi:10.1021/nl901852h

Nyström G, Mihranyan A, Razaq A, Lindström T, Nyholm L, Strømme M (2010) A nanocellulose polypyrrole composite based on microfibrillated cellulose from wood. J Phys Chem B 114(12):4178–4182. doi:10.1021/jp911272m

Omastová M, Trchová M, Kovářová J, Stejskal J (2003) Synthesis and structural study of polypyrroles prepared in the presence of surfactants. Synth Met 138(3):447–455. doi:10.1016/S0379-6779(02)00498-8

Otero TF, Boyano I, Cortés MT, Vázquez G (2004) Nucleation, non-stoiquiometry and sensing muscles from conducting polymers. Electrochim Acta 49(22–23):3719–3726. doi:10.1016/j.electacta.2004.01.085

Ruangchuay L, Schwank J, Sirivat A (2002) Surface degradation of α-naphthalene sulfonate-doped polypyrrole during XPS characterization. Appl Surf Sci 199(1–4):128–137. doi:10.1016/S0169-4332(02)00564-0

Tan KL, Tan BTG, Kang ET, Neoh KG, Ong YK (1990) X-ray photoelectron spectroscopic studies of conductive polypyrrole complexes chemically synthesized with FeCl3. Phys Rev B 42(12):7563–7566. doi:10.1103/PhysRevB.42.7563

Thiéblemont JC, Gabelle JL, Planche MF (1992) Polypyrrole overoxidation during its chemical synthesis. Synth Met 66(3):243–247. doi:10.1016/0379-6779(94)90073-6

Tian B, Zerbi G (1990a) Lattice dynamics and vibrational spectra of pristine and doped polypyrrole: effective conjugation coordinate. J Chem Phys 92(6):3892–3898. doi:10.1063/1.457795

Tian B, Zerbi G (1990b) Lattice dynamics and vibrational spectra of polypyrrole. J Chem Phys 92(6):3886–3891. doi:10.1063/1.457794

Xing S, Zhao G (2007) Morphology, structure, and conductivity of polypyrrole prepared in the presence of mixed surfactants in aqueous solutions. J Appl Polym Sci 104(3):1987–1996. doi:10.1002/app.25912

Xue P, Tao XM (2005) Morphological and electromechanical studies of fibers coated with electrically conductive polymer. J Appl Polym Sci 98(4):1844–1854. doi:10.1002/app.22318

Zhang ZM, Li Q, Yu LM, Cui ZJ, Zhang LJ, Bowmaker GA (2011) Highly conductive polypyrrole/γ-Fe2O3 nanospheres with good magnetic properties obtained through an improved chemical one-step method. Macromolecules 44(12):4610–4615. doi:10.1021/ma2006359

Acknowledgments

We express sincere thanks to NSERC CRD grant (CRDPJ 363811-07), the Canada Research Chairs program, National Science Foundation of China (Grant No. 21204046), the project-sponsored by SRF for ROCS, SEM, Research Foundation of Education Bureau of Shaanxi Province (2010JK440, 2010JK433) and Academic Leaders Cultivation Program of Shaanxi University of Science & Technology (XSG2010014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Leaukosol, N., He, Z. et al. Microstructure, distribution and properties of conductive polypyrrole/cellulose fiber composites. Cellulose 20, 1587–1601 (2013). https://doi.org/10.1007/s10570-013-9945-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-9945-z