Abstract

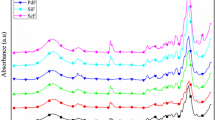

A two step process was used for the cellulose/chitin mix fibers modification: the first one consists in cold plasma activation followed by the second step the reaction with different chemical modifiers by subsequent impregnation or impregnation/coupling reaction. The activation has been performed under the action of four kinds of cold plasma discharges (discharge gases: air, oxygen, nitrogen and argon). The N-isopropylacrylamide, acrylic acid and oleic acid are used as modifiers. The modified samples were characterized by ATR-FTIR spectroscopy, X-ray photoelectron spectroscopy, scanning electron microscopy, thermogravimetry and differential thermal analysis. All results confirm the morphological and structural changes after plasma treatments which determine the modification of the cellulose/chitin mix fibers.

Graphical Abstract

Similar content being viewed by others

References

Biederman H, Osada Y (1992) Plasma polymerization processes. Elsevier Science Publishers, pp 1-5

Blaker JJ, Lee KY, Menner A, Bismarck A (2009) Nanocomposite foams based on renewable resources synthesised from pickering emulsion templates, 17th international conference on composite materials, 27–31 July, Edinburgh International Conference Centre, Edinburgh, Uk, http://www.iccm-central.org/Proceedings/ICCM17proceedings/Themes/Behaviour/SUSTAIN%20GREEN%20COMP/F23.4%20Bismarck.pdf

Bodin A, Gustafsson L, Gatenholm P (2006) Surface-engineered bacterial cellulose as template for crystallization of calcium phosphate. J Biomater Sci Polym Ed 17:435-447

Bryjak M, Gancarz I, Pozniak G (1999) Surface evaluation of plasma-modified polysulfone (Udel P1700) films. Langmuir 15:6400-6404

Chantui DS (2012) Use of chitin in Chinese herb formulas, http://www.google.ro/imgres?imgurl=http://www.itmonline.org/image/chantui1.gif&imgrefurl=http://www.itmonline.org/arts/chantui.htm&h=250&w=383&sz=7&tbnid=QucFFUiMc8J9vM:&tbnh=80&tbnw=123&prev=/search%3Fq%3Dchitin%2Bstructure%26tbm%3Disch%26tbo%3Du&zoom=1&q=chitin+structure&hl=ro&usg=__S8a056m7dB_af1nTV_avXvVOank=&sa=X&ei=0OYzT5bNFcPZtAb4n8DMDA&ved=0CB0Q9QEwAw. Accessed 21 Mar 2012

Choi YJ, Ahn Y, Kang MS, Jun HK, Kim IS, Moon SH (2004) Preparation and characterization of acrylic acid-treated bacterial cellulose cation-exchange membrane. J Chem Technol Biol 79:79-84

Coats AW, Redfern JT (1964) Kinetic parameters from thermogravimetric data. Nature 201:68-69

Flynn JH, Wall LA (1966) A quick, direct method for the determination of activation energy from thermogravimetric data. Polym Lett 4:323-328

Hirano S, Midorikawa T (1998) Novel method for the preparation of N-acylchitosan fiber and N-acylchitosan-cellulose fiber. Biomaterials 19:293-297

Hirano S, Nakahira T, Nakagawa M, Kim SK (1999) The preparation and applications of functional fibres from crab shell chitin. J Biotechnol 70:373-377

Hua Q, Sitaru R, Denes F, Young RA (1997) Mechanisms of oxygen and argon RF plasma—induced surface chemistry of cellulose. Plasmas Polym 2:199-224

Ibrahim NA, Wan Yunus WMZ, Abu-Ilaiwi FA, Ab Rahman MZ, Bin Ahmad M, Dahlan KZM (2003) Graft copolymerization of methyl methacrylate onto oil palm empty fruit bunch fiber using H2O2/Fe2 + as an initator. J Appl Polym Sci 89:2233-2238

Ifuku S, Kadla JF (2008) Preparation of a thermosensitive highly regioselective cellulose/N-Isopropylacrylamide copolymer through atom transfer radical polymerization. Biomacromolecules 9:3308-3313

Kadla JF, Satoshi K (2004) Lignin-based polymer blends: analysis of intermolecular interactions in lignin-synthetic polymer blends. Compos Part A Appl Sci 35:395-400

Karklin VB, Erinsh PP (1971) Infrared spectroscopy of wood and its maio componente I quantitative comparison of infrared spectra in the study of wood and legnin. Khim Drev 7:83

Klemann LP, Yarger RG, You X (1999) Surface modified cellulose as low calorie fluor replacements, US Patent 5906 852

Kotelnikova NI (1992) Lignocellulose’s. In: Kennedy JF, Phillips GO, Williams PA (eds) Science, technology, development and use. Ellis Horwood Limt., p 597

Martin AR, Manolache S, Denes F, Mattoso LHC (2002) Functionalization of sisal fibers and high-density polyethylene by cold plasma treatment. J Appl Polym Sci 85:2145-2154

Oniz-Magan AB, Pastor-Blas MM, Martin-Martinez JM (2005) Different performance of Ar, O2 and CO2 RF plasmas in the adhesion of thermoplastic rubber to polyurethane adhesive. Plasma Process Polym 14:177-191

Park SJ, Kim JS (2001) Influence of plasma treatment on microstructures and acid-base surface energetics of nanostructured carbon blacks: N2 plasma environment. J Colloid Interface Sci 244:336-341

Pimentel GC, Sederholm CH (1956) Correlation of infrared stretching frequencies and hydrogen bond distances in crystals. J Chem Phys 24:639

Popescu MC, Totolin M, Tibirna CM, Sdrobis A, Stevanovic T, Vasile C (2011) Grafting of softwood kraft pulps fibers with fatty acids under cold plasma conditions. Int J Biol Macromol 48:326-335

Raju G, Ratnam CT, Ibrahim NA, Ab Rahman MZ, Yunus WZW (2007) Graft copolymerization of methyl acrylate onto oil palm empty fruit bunch (OPEFB) fibre. Polym Plast Technol Eng 46:949-955

Sdrobiş A, Darie RN, Totolin M, Cazacu G, Vasile C (2012a) Low density polyethylene composites containing cellulose pulp fibers. Compos Part B Eng 43:1873-1880

Sdrobiş A, Ioanid GE, Stevanovic T, Vasile C (2012b) Modification of cellulose/chitin mix fibers with N-isopropylacrylamide and poly (N-isopropylacrylamide) under cold plasma conditions. Polym Int. doi:https://doi.org/10.1002/pi.4268

Shimizu Y, Kanagawa T, Saito Y (2005) Graft copolymerization of acrylic acid onto chitin/cellulose composite fiber. Sci Links Jpn Chitin Chitosan Res 11:53-58

Shyong Siow K, Britcher L, Kumar S, Griesser JH (2006) Plasma methods for the generation of chemically reactive surfaces for biomolecule immobilization and cell colonization—A review. Plasma Process Polym 3:392-418

Singha AS, Rana AK (2011) Kinetics of graft copolymerization of acrylic acid onto cannabis indica fibre. Iran Polym J 20:913-929

Struszczyk H (1986) Modification of lignins. III. Reaction of lignosulfonates with chlorophosphazenes. J Macromol Sci A 23:973-992

Takegawa A, Murakami M, Kaneko Y, Kadokawa J (2010) Preparation of chitin/cellulose composite gels and films with ionic liquids. Carbohyd Polym 79:85-90

Totolin M, Vasile C, Tibirna CM, Popescu MC (2008) Grafting of Spanish broom (Spartium Junceum) fibers with fatty acids under cold plasma conditions. Cell Chem Technol 42:317-333

Urbanovici E, Segal E (1984) A new integral method of non-isothermal kinetic data evaluation. Thermochim Acta 80:389-393

Vasile C, Baican MC, Tibirna CM, Tuchilus C, Debarnot D, Pâslaru E, Poncin-Epaillard F (2011) Microwave plasma activation of a polyvinylidene fluoride surface for protein immobilization. J Phys D Appl Phys 44:475303

Wan CH, Kuo JF (2001) Infrared spectroscopic and mesomorphic studies of 4,4′-bis(-hydroxyalkoxy)-methylstilbenes. Liq Cryst 28:535-548

Zoppe JO, Venditti RA, Rojas OJ (2012) Pickering emulsions stabilized by cellulose nanocrystals grafted with thermo-responsive polymer brushes. J Colloid Interface Sci 369:202-209

Acknowledgments

This work was done in the framework of the project BIONANOMED 164/2012 financed by Romanian UEFISCDI.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sdrobiş, A., Kylian, O., Biederman, H. et al. Modification of cellulose/chitin mix fibers under different cold plasma conditions. Cellulose 20, 509–524 (2013). https://doi.org/10.1007/s10570-012-9842-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9842-x