Abstract

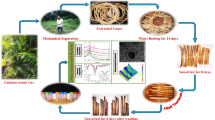

The microstructure and chemical composition of alfa (Stipa tenacissima) were investigated. The polysaccharide and lignin contents were around 70 and 20 wt%, respectively. From the bleached and delignified fibers, two types of nanosized cellulosic particles were extracted, namely cellulose nanocrystals and microfibrillated cellulose (MFC). The former correspond typically to the elementary crystallite units of the cellulose fibers, with a rod-like morphology and an aspect ratio of about 20. The latter, mechanically disintegrated from oxidized bleached fibres, presents an entangled fibrillar structure with widths in the range 5-20 nm. The reinforcing potential of the ensuing nanoparticles was investigated by casting a mixture of acrylic latex and aqueous dispersion of cellulose nanoparticles. Thermo-mechanical analysis revealed a huge enhancement of the stiffness above the glass transition of the matrix. Significant differences in the mechanical reinforcing capability of the nanoparticles were reported.

Similar content being viewed by others

References

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6:612–626

Ben Brahim S, Ben Cheikh R (2007) Influence of fiber orientation and volume fraction on the tensile properties of unidirectional Alfa polyester composite. Compos Sci Technol 67:140–147

Bendahou A, Habibi Y, Kaddami H, Dufresne A (2009) Physico-chemical characterization of palm from phoenix dactylifera–L, preparation of cellulose whiskers and natural rubber–based nanocomposites. J Biobased Mat Bioenerg 3:1–10

Bendahou A, Kaddami H, Dufresne A (2010) Investigation on the effect of cellulosic nanoparticles morphology on the properties of natural rubber based nanocomposites. Eur Polym J 46:609–620

Besbes I, Alila S, Boufi S (2011) Nanofibrillated cellulose from TEMPO-oxidized eucalyptus fibres: effect of the carboxyl content. Carbohydr Polym 84:975–983

Bessadok A, Marais S, Gouanve F, Colasse L, Zimmerlin I, Roudesli S, Métayer M (2007) Effect of chemical treatments of alfa (Stipa tenacissima) fibres on water-sorption properties. Compos Sci Technol 67:685–697

Bouiri B, Amrani M (2009) Production of dissolving grade pulp from alfa. BioResources 5:291–302

Cranston ED, Gray DG (2008) Birefringence in spin-coated films containing cellulose nanocrystals. Col Surf A 325:44–51

de Souza Lima M, Borsali R (2004) Rodlike cellulose microcrystals: structure, properties, and applications. Macromol Rapid Comm 25:771–774

Dufresne A (2000) Dynamic mechanical analysis of the interphase in bacterial polyester/cellulose whiskers natural composites. Compos Interfaces 7:53–67

Dufresne A (2008) Polysaccharide nanocrystals reinforced nanocomposites. Can J Chem 86:484–494

Frisch HL, Mark EJ (1996) Nanocomposites prepared by threading polymer chains through zeolites, mesoporous silica, or silica nanotubes. Chem Mater 8:1735–1738

Goetz L, Mathew A, Oksman K, Gatenholm P, Ragauskas AJ (2009) A novel nanocomposite film prepared from crosslinked cellulosic whiskers. Carbohydr Polym 75:85–89

Harris PJF (2004) Carbon nanotube composites. Int Mater Rev 49:31–43

Kaddami H, Gérard JF, Pascault JP (2004) Influence of the initiation rate on the polymerization kinetics of hydroxy ethyl methacrylate (HEMA) filled with HEMA-grafted silica preformed nanoparticles. Polym Eng Sci 44:1231–1939

Kaddami H, Becker-Villinger C, Schmidt H (2006) Monitoring morphology and properties of hybrid organic-inorganic materials from in situ polymerization of tetraethoxysilane in polyimide polymer: 1) effect of the coupling agent on the microstructure and interfacial interaction. E-Polymers 10:1–10

Khiari R, Mhenni MF, Belgacem MN, Mauret E (2010) Chemical composition and pulping of date palm rachis and Posidonia oceanica – A comparison with other wood and non-wood fibre sources. Biores Technol 101:775–780

Lau KT, Gu C, Hui D (2006) A critical review on nanotube and nanotube/nanoclay related polymer composite materials. Composites B 37:425–436

Motomatsu M, Takahashi T, Nie HY, Mizutani W, Tokumoto H (1997) Microstructure study of acrylic polymer-silica nanocomposite surface by scanning force microscopy. Polymer 38:177–182

Okada A, Kawasumi M, Usuki A, Kojima Y, Kurauchi T, Kamigaito O (1990) Nylon 6-clay hybrid. Mater Res Soc Proc 171:45–50

Paiva MC, Ammar I, Campos AR, Ben Cheikh R, Cunha AM (2007) Alfa fibers: mechanical, morphological and interfacial characterization. Compos Sci Technol 67:1132–1138

Pit Z, Mark EJ, Jethmalani JM, Ford WT (1996) Mechanical properties of a poly(methvl acrvlate) nanocomposite containing regularly-arranged silica particles. Polym Bull 37:545–551

Röser M, Heklau H (2011) Abscission of leaf laminas—an unnoticed factor in tussock grass formation. Flora 206:32–37

Ruckenstein E, Yuan Y (1997) Nanocomposites of rigid polyamide dispersed in flexible vinyl. Polymer 38:3855–3860

Saito T, Hirota M, Tamura N, Kimura S, Fukuzumi H, Heux L, Isogai A (2009) Individualization of nano-sized plant cellulose fibrils by direct surface carboxylation using TEMPO catalyst under neutral conditions. Biomacromolecules 10:1992–1996

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimation the degree of crystallinity of native cellulose using the X-ray diffractometer. Textile Res J 29:786–794

Siqueira G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: influence of nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 10:425–432

Siqueira G, Bras J, Dufresne A (2010) Luffa cylindrica as a lignocellulosic source of fiber, microfibrillated cellulose, and cellulose nanocrystals. BioResources 5727–740

Sirò I, Plackett D (2010) Microfibrillated cellulose and new nanocomposites materials: a review. Cellulose 17:459–494

Terre et Vie (2002), L’Alfa : Importance écologique et socio-économique, N° 61–62. (http://www.terrevie.ovh.org/Alfa.pdf)

Acknowledgments

The authors thank for their financial support Hassan II Academy of Sciences and Techniques, the French Ministry of Foreign Affairs (Corus program 6046), the PHC-UTIQUE (Grant 11/G 1115) and the Tunisian Ministry of Higher Education and Scientific Research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mabrouk, A.B., Kaddami, H., Boufi, S. et al. Cellulosic nanoparticles from alfa fibers (Stipa tenacissima): extraction procedures and reinforcement potential in polymer nanocomposites. Cellulose 19, 843–853 (2012). https://doi.org/10.1007/s10570-012-9662-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9662-z