Abstract

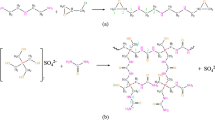

An organic phosphorus compound (flame retardant agent, FR) in combination with a melamine resin (crosslinking agent, CL), phosphoric acid (catalyst, PA) and zinc oxide (co-catalyst, ZnO/nano-ZnO) imparted effective and durable flame retardant properties. Also, atmospheric pressure plasma jet was applied as pre-treatment to improve post-finishing (flame retardant finishing) on cotton fabrics. In the present paper, surface morphology, chemical structure analysis, combustibility and mechanical properties of plasma pre-treated cotton fabrics subjected to flame-retardant treatment were investigated. Surface morphology of treated cotton specimens showed roughened and wrinkled fabric surface with high deposition of the flame retardant finishing agent, which was caused by the plasma etching effect and attack of acidic FR. The FTIR-ATR spectra for the treated cotton specimens showed some new characteristic peaks in chemical structure, interpreted as carbonyl bands, OH stretching vibration, COO− stretching vibration, CH2 rocking band and CH3 asymmetric and CH2 symmetric stretching. Moreover, FR-CL-PA-treated specimens showed remarkable flame-retardant property, which was further improved by the plasma pre-treatment and ZnO/nano-ZnO co-catalyst. However, flame-retardant-treated cotton specimens had poor mechanical strength when compared with control sample, resulting from side effects of the crosslinking agent used, while plasma pre-treatment and ZnO/nano-ZnO co-catalyst may compensate for the reduction in tensile and tearing strength caused by flame-retardant agents.

Similar content being viewed by others

References

Bourbigot S, Duquesne S (2007) Fire retardant polymers: recent developments and opportunities. J Mater Sci 12:2283–2300

Ceach V, Prikryl R, Balkova R, Grycova A, Vanek J (2002) Plasma surface treatment and modification of glass fibres. Compos Part A 33:1367–1372

Gaan S, Sun G (2007) Effect of phosphorus and nitrogen on flame retardant cellulose: a study of phosphorus compounds. J Anal Appl Pyrol 78(2):371–377

Guan JP, Chen GQ (2006) Flame retardancy finish with an organophosphorus retardant on silk fabrics. Fire Mater 30(6):415–424

Holme I (2007) Flame retardants: new approaches. Int Dyer 192(8):17–19

Hwang YJ, Mccord MG (2005) Effects of helium atmospheric pressure plasma treatment on low-stress mechanical properties of polypropylene nonwoven fabrics. Tex Res J 75(11):771–778

Kan CW, Yuen CWM, Lam YL, Chan CK (2009) Effect of enzymatic treatment and reactive dyeing on the low stress mechanical properties of linen fabric. Fibers Polym 10(3):325–332

Kang I, Yang CQ, Wei W, Lickfield GC (1998) The mechanical strength of cotton fabrics crosslinked by polycarboxylic acids: part I: acid degradation and crosslinking of cellulose. Tex Res J 68:865–870

Kaplan S (2004) Plasma processes for wide fabric, film and non-wovens. Surf Coatings Technol 186:214–217

Katović D, Vukušić SB, Grgac SF, Lozo B, Banić D (2009) Flame retardancy of paper obtained with environmentally friendly agents. Nucl Med Rev Cent East Eur 17(3):90–94

Lam YL, Kan CW, Yuen CWM (2010) Flame-retardant finishing in cotton fabrics using zinc oxide co-catalyst. J Appl Polym Sci (Submitted)

Laoutid F, Bonnaud L, Alexandre M, Lopez-Cuesta JM, Dubois Ph (2009) New prospects in flame retardant polymer materials: from fundamentals to nanocomposites. Mater Sci Eng R Rep 63(3):100–125

Lewin M (2001) Synergism and catalysis in flame retardancy of polymers. Polym Adv Technol 12(3–4):215–222

Lewin M, Endo M (2003) Catalysis of intumescent flame retardancy of polypropylene by metallic compounds. Polym Adv Technol 14(1):3–11

Mostashari SM, Mostashari SZ (2004) Burning of cotton fabric impregnated by ammonium chloride as a flame-retardant. J Appl Fire Sci 13(4):329–337

Mostashari SM, Mostashari SZ (2005) Synergistic effect of boric acid-urea on the flame retardancy imparted to cotton fabric. Chem Asian J 17(4):2331–2334

Pappas D, Bujanda A, Demaree JD, Hirvonen JK, Kosik W, Jensen R, McKnight S (2006) Surface modification of polyamide fibers and films using atmospheric plasmas. Surf Coatings Technol 201(7):4384–4388

Rajpreet KV, Gita NR (2004) Plasma and antimicrobial treatment of nonwoven fabrics for surgical gowns. Tex Res J 74(12):1073–1079

Siriviriyanun A, O’Rear EA, Yanumet N (2008) Self-extinguishing cotton fabric with minimal phosphorus deposition. Cellulose 15(5):731–737

Sun J, Gao L, Zhang QH (2003) Synthesizing and comparing the photocatalytic properties of high surface area rutile and anatase tiania nanoparticles. J Am Ceram Soc 86(10):1677–1682

Titov VA, Rybkin VV, Shikova TG, Ageeva TA, Golubchikov OA, Choi HS (2005) Study on the application possibilities of an atmospheric pressure glow discharge with liquid electrolyte cathode for the modification of polymer materials. Surf Coatings Techn 199(2–3):231–236

Wakelyn PJ, Adair PK, Barker RH (2004) Do open flame ignition resistance treatments for cellulosic and cellulosic blend fabrics also reduce cigarette ignitions? Fire Mater 29(1):15–26

Wang CX, Qiu YP (2007) Two sided modification of wool fabrics by atmospheric pressure plasma jet—influence of processing parameters on plasma penetration. Surf Coatings Technol 201:6273–6277

Wang CX, Liu Y, Xu HL, Ren Y, Qiu YP (2008) Influence of atmospheric pressure plasma treatment time on penetration depth of surface modification into fabric. Appl Surf Sci 254(8):2499–2505

Wang JS, Liu Y, Zhao HB, Liu J, Wang DY, Song YP, Wang YZ (2009) Metal compound-enhanced flame retardancy of intumescent epoxy resins containing ammounium polyphosphate. Polym Degrad Stab 94(4):625–631

Well ED (2008) Flame retardants in commercial use or development for textiles. J Fire Sci 26(3):243–281

Well ED, Levchik S (2004) Current practice and recent commercial developments in flame retardancy of polyamides. J Fire Sci 22(3):251–264

Wong KK, Tao XM, Yuen CWM, Yeung KW (1999) Low temperature plasma treatment of linen. Tex Res J 69(11):846–855

Wu XL (2009) Flame retardant finishing of cotton fleece fabric: part IV-bifunctional carboxylic acids. J Fire Sci 27(9):431–446

Wu WD, Yang CQ (2004a) Comparison of DMDHEU and melamine-formaldehyde as the binding agents for a hydroxy-functional organophosphorus flame retarding agent on cotton. J Fire Sci 22(3):125–142

Wu WD, Yang CQ (2004b) Statistical analysis of the performance of the flame retardant finishign system consisting of a hydroxy-functional organophosphorus oligomer and the mixture of DMDHEU and melamine—formaldehyde resin. Polym Degrad Stab 85:623–632

Wu WD, Yang CQ (2006) Comparison of different reactive organophosphorus flame retardant agents for cotton: part I. The bonding of the flame retardant agents to cotton. Polym Degrad Stab 91(11):2541–2548

Wu XL, Yang CQ (2008) Flame retardant finishing of cotton fleece fabric: part III—the combination of maleic acid and sodium hyphosphite. J Fire Sci 26(4):351–368

Yadav A, Prasad V, Kathe AA, Raj S, Yadav D, Sundaramoorthy C, Vigneshwaran N (2006) Functional finishing in cotton fabrics using zinc oxide nanoparticles. Bull Mater Sci 29(6):641–645

Yang CQ (1991) Characterizing ester crosslinkages in cotton cellulose with FTIR photoacoustic spectroscopy 1. Tex Res J 61(5):298–305

Yang CQ, Bakshi GD (1996) Quantitative analysis of the nonformaldehyde durable press finish on cotton fabric: acid-base titration and infrared spectroscopy. Tex Res J 66(6):377–384

Yang CQ, Qiu XQ (2007) Flame-retardant finishing of cotton fleece fabric: part I. The use of a hydroxy-functional organophosphorus oligomer and dimethyloldihydroxylethyleneurea. Fire Mater 31:67–81

Yang H, Yang CQ (2005) Durable flame retardant finishing of the nylon/cotton blend fabric using a hydroxyl-functional organophosphorus oligomer. Polym Degrad Stab 88(3):363–370

Yang H, Yang CQ (2007) Nonformaldehyde flame retardant finishing of the Nomex/Cotton blend fabric using a hydroxy-functional organophosphorus oligomer. J Fire Sci 25(5):425–446

Yang CQ, Wei W, Lickfield GC (2000) Mechanical strength of durable press finsihed cotton fabric: part III: Change in cellulose molecular weight. Tex Res J 70:910–915

Zhang HJ, Zhang ZZ, Guo F, Liu WM (2008) The influence of plasma treatment on the tribological properties of hybrid PTFE/cotton fabric/phenolic composites. Polym Compos 30(10):1523–1531

Acknowledgments

This work was supported by a grant from the Research Grant Council of the Hong Kong Special Administrative Region, China, under project PolyU 5192/08E and financial assistance from the Institute of Textile and Clothing, The Hong Kong Polytechnic University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lam, Y.L., Kan, C.W. & Yuen, C.W.M. Effect of zinc oxide on flame retardant finishing of plasma pre-treated cotton fabric. Cellulose 18, 151–165 (2011). https://doi.org/10.1007/s10570-010-9466-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-010-9466-y