Abstract

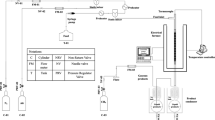

Zeolites are crystalline aluminosilicates with open-framework structures and have been widely used in refinery processes. One of the significant utilization processes is cracking heavy feedstocks into lighter fractions, which can be used as a feedstock for subsequent processes such as petrochemical applications. This work aimed to study the effect of the zeolite’s different Si/Al ratios on heavy crude cracking under different salt content conditions. The feedstock used for this study is a heavy hydrocarbon fraction contains a large amount of metal and salt. Two synthesized prototype catalysts were prepared and characterized by different physical–chemical methods (SEM–EDX, XRD, N2 physisorption, TPD and TGA). Later the catalysts were mixed with the crudes in a 500 ml autoclave and the catalytic activities were performed in a batch reactor at a temperature of 380–450 °C, 150 rpm, and nitrogen pressure of 10 MPa. The reaction’s outlet gases were analysed directly in online Gas Chromatography (GC). The results showed a wide range of impacts on catalyst performance and a noticeable increase in C2 and C3 yield for the desalted crude. Moreover, a higher C3 was produced for both catalysts at 430–450 °C due to the catalyst’s large pore.

Graphical Abstract

Similar content being viewed by others

References

Al-Ghamdi MS, Bahammam B, Al Osaimi N, Barnawi S (2020) System for conversion of crude oil to petrochemical and fuel production integrating delayed cocking of vacuum residue. USP Application 20200123450 A1

Meyers RA (2016) Chapter 6.2. UOP Unicracking™ process for hydrocracking. Handbook of petroleum refining processes, 4th edn. McGraw-Hill Education, New York (ISBN: 9780071850490)

IEA (2020) World Energy Investment Report 2020. IEA, Paris. Accessed 28 May 2020

Clarence Neilson J, Hume S, Lincoln B (1942) Determination of salts in crude oil. Ind Eng Chem Anal Ed 14(6):464–465. https://doi.org/10.1021/i560106a006

Abdel-Aal HK, Zohdy K, Abdelkreem M (2018) Waste management in crude oil processing: crude oil dehydration and desalting. Int J Waste Resour 8:326. https://doi.org/10.4172/2252-5211.1000326

Weitkamp J (2008) Handbook of heterogeneous catalysis. Gerhard Ertl

Mohammed A et al (2020) A viewpoint on the refinery of the future: catalyst and process challenges. ACS Catal 10(15):8131–8140

Ramirez-Corredores C, Magdalena M (2017) Chapter 8—Final remarks and future aspirations. In: Ramirez-Corredores MM (ed) The science and technology of unconventional oils. Academic, Amsterdam, pp 695–741

Amghizar I, Vandewalle LA, Van Geem KM, Marin GB (2017) New trends in olefin production. Engineering 3(2):171–178

Bourane A, Shafi R, Sayed E, Abba I, Akhras ARZ (2013) Integrated hydrotreating, solvent deasphalting and steam pyrolysis process for direct processing of a crude oil. WO2013112968, Jan 27

Maldonado K, Oleksiak MD, Chinta S, Rimer JD (2013) Controlling crystal polymorphism in organic-free synthesis of Na-zeolites. J Am Chem Soc 135(7):2641–2652

Bleken FL, Chavan S, Olsbye U, Boltz M, Ocampo F, Louis B (2012) Conversion of methanol into light olefins over ZSM-5 zeolite: strategy to enhance propene selectivity. Appl Catal A Gen 447–448:178–185

Bellussi G, Pollesel P (2005) Industrial applications of zeolite catalysts: production and uses of light olefins. Stud Surf Sci Catal 158:1201–1212

Li J, Corma A, Yu J (2015) Synthesis of new zeolite structures. Chem Soc Rev 44(20):7112–7127

Degnan TF (2007) Recent progress in the development of zeolitic catalysts for the petroleum refining and petrochemical manufacturing industries. Stud Surf Sci Catal 170:54–65

Verboekend D, Nuttens N, Locus R, Van Aelst J, Verolme P, Groen JC, Sels BF (2016) Synthesis, characterisation, and catalytic evaluation of hierarchical faujasite zeolites: milestones, challenges, and future directions. Chem Soc Rev 45(12):3331–3352

Mallada R (2015) Hydrothermal stability of zeolite. In: Drioli E, Giorno L (eds) Encyclopedia of membranes. Springer Berlin Heidelberg, Berlin, pp 1–2

Xie LF, Duan PG, Jiao JL, Xu YP (2019) Hydrothermal gasification of microalgae over nickel catalysts for production of hydrogen-rich fuel gas: effect of zeolite supports. Int J Hydrogen Energy 44(11):5114–5124. https://doi.org/10.1016/j.ijhydene.2018.09.175

Alabdullah M, Shoinkhorova T, Gomez A, Dikhtiarenko J, Vittenet OS, Ali IM, Osorio W, Xu J (2021) Gascon composition-performance relationships in catalysts formulation for the direct conversion of crude oil to chemicals. ChemCatChem 13(7):1806–1813

Stamires D, O’Connor P, Hakuli-Pieterse A, Laheij RR (2006) Catalyst for the production of light olefins. US20070060780, Jun 21

ASTM D3230-19 (2019) Standard test method for salts in crude oil (electrometric method). ASTM International, West Conshohocken, PA. www.astm.org

Vogt ETC, Weckhuysen BM (2015) Fluid catalytic cracking: recent developments on the grand old lady of zeolite catalysis. Chem Soc Rev 44(20):7342–7370

“News & Events.” Koehler Instrument Company Inc, koehlerinstrument.com/new-salts-in-crude-analyzer/

Zaman S, Zhang S, Shah R. Salt in crude oil analyzer. Koehler Instruments Company, Inc

Babalola FU, Susu AA (2019) Pre-treatment of heavy crude oils for refining. IntechOpen, Rijeka. https://doi.org/10.5772/intechopen.89486

Sahu R, Song BJ, Im JS, Jeon Y-P, Lee CW (2015) A review of recent advances in catalytic hydrocracking of heavy residues. J Ind Eng Chem 27:12–24. https://doi.org/10.1016/j.jiec.2015.01.011

Castañeda LC, Muñoz JAD, Ancheyta J (2014) Current situation of emerging technologies for upgrading of heavy oils. Catal Today 220–222:248–273. https://doi.org/10.1016/j.cattod.2013.05.016

Xie C, Zhang J, Jun L, Xiaoli W, Chaogang X, Youhao X, Xu Y (2010) Petroleum hydrocarbon catalytic conversion method. CN102344831, Jul 29

Kuzhaeva A et al (2019) The processes of hydrocarbon conversion using catalytic systems. J Phys Conf Ser 1399:022057. https://doi.org/10.1088/1742-6596/1399/2/022057

Rana MS, AlHumaidan FS, Bouresli R, Navvamani R (2021) Guard-bed catalyst: impact of textural properties on catalyst stability and deactivation rate. Mol Catal 502:111375

Al-Samhan M, Al-Fadhli J, Al-Otaibi AM, Bouresli R (2023) Synthesis of micromesoporous zeolite-alumina catalysts for olefin production from heavy crude oil. Int J Chem Eng 2023:7302409. https://doi.org/10.1155/2023/7302409

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al-Samhan, M., Al-Fadhli, J. Synthesis and Assessment of Y-Zeolite Catalyst for Direct Olefin Production from Heavy Feedstock: An Effect of Feed Composition. Catal Lett (2024). https://doi.org/10.1007/s10562-024-04635-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10562-024-04635-9