Abstract

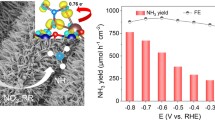

Electrochemically converting nitrate into ammonia (ECNA) is expected to achieve wastewater treatment combined with distributed ammonia generation, which is beneficial to restoring the globally disrupted nitrogen cycle. While sluggish reaction kinetics and insufficient selectivity towards ammonia generation greatly hinder the practical application of ECNA. In this study, chloride-derived bimetallic Cu–Fe catalysts with flexible Cu/Fe ratios confined by nitrogen-doped carbon (CuxFey/CN) were constructed through reactive mechanical milling combined with thermal pyrolysis, enabling stable and efficient nitrate-to-ammonia conversion. The CN coating effectively prevents further oxidation of Fe2+, promoting electron transfer from Fe2+ to Cu+ and maintaining the highly reactive center Cu+/Cu stable. The optimized Cu3Fe/CN700-15 sample exhibits good nitrate conversion efficiency of 57.0% and ammonium selectivity of 61.6% within 6 h at −0.7 V relative to the reversible hydrogen electrode (vs. RHE). This work provides a new idea for stable and sustainable bimetallic denitrification.

Graphical Abstract

Similar content being viewed by others

References

Lim J, Fernández CA, Lee SW, Hatzell MC (2021) Ammonia and nitric acid demands for fertilizer use in 2050. ACS Energy Lett 6(10):3676–3685

Lan R, Irvine JTS, Tao S (2012) Ammonia and related chemicals as potential indirect hydrogen storage materials. Int J Hydrogen Energy 37(2):1482–1494

Tang C, Qiao S-Z (2019) How to explore ambient electrocatalytic nitrogen reduction reliably and insightfully. Chem Soc Rev 48(12):3166–3180

Jiang B, Xue H, Wang P, Du H, Kang Y, Zhao J, Wang S, Zhou W, Bian Z, Li H, Henzie J, Yamauchi Y (2023) Noble-metal–metalloid alloy architectures: mesoporous amorphous iridium-tellurium alloy for electrochemical N2 reduction. J Am Chem Soc 145(11):6079–6086

Chen J-Q, Ye X-X, Zhou D, Chen Y-X (2023) Roles of copper in nitrate reduction at copper-modified Ru/C catalysts. J Phys Chem C 12(6):2918–2928

Wang Y, Zhou W, Jia R, Yu Y, Zhang B (2020) Unveiling the activity origin of a copper-based electrocatalyst for selective nitrate reduction to ammonia. Angew Chem Int Ed 59(13):5350–5354

Afif A, Radenahmad N, Cheok Q, Shams S, Kim JH, Azad AK (2016) Ammonia-fed fuel cells: a comprehensive review. Renew Sustain Energy Rev 60:822–835

Aziz M, Wijayanta AT, Nandiyanto ABD (2020) Ammonia as effective hydrogen storage: a review on production. Storage Util Energies 13(12):3062

Qin J, Wu K, Chen L, Wang X, Zhao Q, Liu B, Ye Z (2022) Achieving high selectivity for nitrate electrochemical reduction to ammonia over MOF-supported RuxOy clusters. J Mater Chem A 10(8):3963–3969

Liu P, Yan J, Huang H, Song W (2023) Cu/Co bimetallic conductive MOFs: electronic modulation for enhanced nitrate reduction to ammonia. Chem Eng J 466:143134

Sanchis I, Diaz E, Pizarro AH, Rodriguez JJ, Mohedano AF (2022) Nitrate reduction with bimetallic catalysts. A stability-addressed overview. Sep Purif Technol 290:120750

Kong X, Zhao X, Li C, Jia Z, Yang C, Wu Z, Zhao X, Zhao Y, He F, Ren Y, Yang P, Liu Z (2023) Terminal group-oriented self-assembly to controllably synthesize a layer-by-layer SnSe 2 and MXene heterostructure for ultrastable lithium storage. Small 19(14):2206563

Wan C, Li G, Wang J, Xu L, Cheng D, Chen F, Asakura Y, Kang Y, Yamauchi Y (2023) Modulating electronic metal-support interactions to boost visible-light-driven hydrolysis of ammonia borane: nickel-platinum nanoparticles supported on phosphorus-doped titania. Angew Chem Int Ed 62(40):e202305371

Jiang B, Guo Y, Sun F, Wang S, Kang Y, Xu X, Zhao J, You J, Eguchi M, Yamauchi Y, Li H (2023) Nanoarchitectonics of metallene materials for electrocatalysis. ACS Nano 17(14):13017–13043

Kang Y, Cretu O, Kikkawa J, Kimoto K, Nara H, Nugraha AS, Kawamoto H, Eguchi M, Liao T, Sun Z, Asahi T, Yamauchi Y (2023) Mesoporous multimetallic nanospheres with exposed highly entropic alloy sites. Nat Commun 14(1):4182

Wang C, Liu Z, Hu T, Li J, Dong L, Du F, Li C, Guo C (2021) Metasequoia-like nanocrystal of iron-doped copper for efficient electrocatalytic nitrate reduction into ammonia in neutral media. ChemSusChem 14(8):1825–1829

Tang Z, Bai Z, Li X, Ding L, Zhang B, Chang X (2022) Chloride-derived bimetallic Cu-Fe nanoparticles for high-selective nitrate-to-ammonia electrochemical catalysis. Processes 10(4):751

Roy C, Deschamps J, Martin MH, Bertin E, Reyter D, Garbarino S, Roué L, Guay D (2016) Identification of Cu surface active sites for a complete nitrate-to-nitrite conversion with nanostructured catalysts. Appl Catal B 187:399–407

Çirmi D, Aydın R, Köleli F (2015) The electrochemical reduction of nitrate ion on polypyrrole coated copper electrode. J Electroanal Chem 736:101–106

Conway BE, Jerkiewicz G (2000) Relation of energies and coverages of underpotential and overpotential deposited H at Pt and other metals to the ‘volcano curve’ for cathodic H2 evolution kinetics. Electrochim Acta 45(25–26):4075–4083

Lin D, Zhang S, Liu W, Yu Y, Zhang J (2019) Carburization of Fe/Ni catalyst for efficient growth of single-walled carbon nanotubes. Small 15(35):1902240

Zhang R, Zhang Y, Wei F (2017) Controlled synthesis of ultralong carbon nanotubes with perfect structures and extraordinary properties. Acc Chem Res 50(2):179–189

Zheng G, Irle S, Morokuma K (2006) Fe/C interactions during SWNT growth with C2 feedstock molecules: a quantum chemical molecular dynamics study. J Nanosci Nanotechnol 6(5):1259–1270

He M, Magnin Y, Jiang H, Amara H, Kauppinen EI, Loiseau A, Bichara C (2018) Growth modes and chiral selectivity of single-walled carbon nanotubes. Nanoscale 10(14):6744–6750

Shiozawa H, Kramberger C, Pfeiffer R, Kuzmany H, Pichler T, Liu Z, Suenaga K, Kataura H, Silva SRP (2010) Catalyst and chirality dependent growth of carbon nanotubes determined through nano-test tube chemistry. Adv Mater 22(33):3685–3689

Luo Z, Liu M, Tang D, Xu Y, Ran H, He J, Chen K, Sun J (2022) High H2O2 selectivity and enhanced Fe2+ regeneration toward an effective electro-Fenton process based on a self-doped porous biochar cathode. Appl Catal B 315:121523

Zhang L, Gu T, Lu K, Zhou L, Li D, Wang R (2021) Engineering synergistic edge-N dipole in metal-free carbon nanoflakes toward intensified oxygen reduction electrocatalysis. Adv Func Mater 31(42):2103187

Xu J, Hao Z, Xie C, Lv X, Yang Y, Xu X (2012) Promotion effect of Fe2+ and Fe3O4 on nitrate reduction using zero-valent iron. Desalination 284:9–13

Zhou J, Pan F, Yao Q, Zhu Y, Ma H, Niu J, Xie J (2022) Achieving efficient and stable electrochemical nitrate removal by in-situ reconstruction of Cu2O/Cu electroactive nanocatalysts on Cu foam. Appl Catal B 317:121811

Shen Z, Yan J, Wang M, Xing L, Huang B, Zhou H, Li W, Chen L, Shi J (2023) Cu/Cu+ synergetic effect in Cu2O/Cu/CF electrocatalysts for efficient nitrate reduction to ammonia. ACS Sustain Chem Eng 11(25):9433–9441

Wang C, Ye F, Shen J, Xue K-H, Zhu Y, Li C (2022) In situ loading of Cu2 O active sites on island-like copper for efficient electrochemical reduction of nitrate to ammonia. ACS Appl Mater Interfaces 14(5):6680–6688

Bi Z, Zhang W, Ni M, Song G, Huang Y (2020) Fe0 /Fe2+ -dependent nitrate reduction in Anammox consortia questions the enzymatic mechanism of nitrate reduction by Anammox bacteria. ACS Sustain Chemi Eng 8(40):15278–15287

Liu C, Zhang G, Zhang W, Gu Z, Zhu G (2023) Specifically adsorbed ferrous ions modulate interfacial affinity for high-rate ammonia electrosynthesis from nitrate in neutral media. Proc Natl Acad Sci 120(3):e2209979120

Yoo JM, Shin H, Chung DY, Sung Y-E (2022) Carbon shell on active nanocatalyst for stable electrocatalysis. Acc Chem Res 55(9):1278–1289

Sun J, Gao W, Fei H, Zhao G (2022) Efficient and selective electrochemical reduction of nitrate to N2 by relay catalytic effects of Fe-Ni bimetallic sites on MOF-derived structure. Appl Catal B 301:120829

Han S, Li H, Li T, Chen F, Yang R, Yu Y, Zhang B (2023) Ultralow overpotential nitrate reduction to ammonia via a three-step relay mechanism. Nat Catal 6(5):402–414

Liu Z, Zhang S, Li J, Ma L (2014) Promoting effect of MoO3 on the NOx reduction by NH3 over CeO2/TiO2 catalyst studied with in situ DRIFTS. Appl Catal B 144:90–95

Funding

This work was supported by the Natural Science Foundation of China (52101279), the Natural Science Foundation of Hunan Province (2020JJ5688), the Science Research Initiation Fund of Central South University (202045012), The Scientific Research Project of Education Department of Hunan Province (21B000).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, X., Bai, Z., Tang, Z. et al. Denitrification Performance and Mechanism of Nitrogen Doped Carbon Coated Cu–Fe Nanoalloy. Catal Lett (2024). https://doi.org/10.1007/s10562-023-04574-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10562-023-04574-x