Abstract

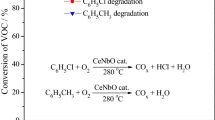

CH4 combustion is one of the effective ways to reduce atmospheric lean CH4. Herein, a series of La-Co-Cu-O catalysts were successfully prepared by sol–gel method and applied to CH4 combustion. The doping of Cu could improve the catalytic activity of LaCoO3 catalyst. Among the samples, La0.85Cu0.15CoO3 and LaCu0.15Co0.85O3 with the same Cu doping amount exhibited better catalytic performance. Compared with LaCu0.15Co0.85O3, La0.85Cu0.15CoO3 catalyst with better redox ability and stronger adsorption capacity for CH4 and O2, exhibited higher reactivity in CH4 combustion. It was proposed that the coexistence of exposed dispersed Co3O4 particles and Cu ions in the system of La0.85Cu0.15CoO3 could lead to relatively better redox ability and stronger adsorption capacity for CH4 combustion. The La0.85Cu0.15CoO3 is proved to be an extremely valuable and potential catalyst for CH4 combustion.

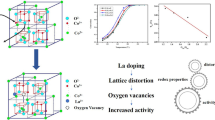

Graphical abstract

Similar content being viewed by others

References

Xu C-G, Zhang W, Yan K-F, Cai J, Chen Z-Y, Li X-S (2022). Chem Eng Sci. https://doi.org/10.1016/j.ces.2021.117266

Chen L, Qi Z, Zhang S, Su J, Somorjai GA (2020). Catalysts. https://doi.org/10.3390/catal10080858

Cui X, Li H, Wang Y, Hu Y, Hua L, Li H, Han X, Liu Q, Yang F, He L, Chen X, Li Q, Xiao J, Deng D, Bao X (2018) Chem 4:1902–1910. https://doi.org/10.1016/j.chempr.2018.05.006

He X, Wang Y, Li K, Wang H, Jiang L, Yuan K, Zheng Y (2022). J CO2 Util. https://doi.org/10.1016/j.jcou.2022.102124

Kang H-S, Lee DH, Kim K-T, Jo S, Pyun S, Song Y-H, Yu S (2016) Fuel Process Technol 148:209–216. https://doi.org/10.1016/j.fuproc.2016.02.028

Jin Z, Wang L, Zuidema E, Mondal K, Zhang M, Zhang J, Wang C, Meng X, Yang H, Mesters C (2020) Science 367:193–197. https://doi.org/10.1126/science.aaw1108

Yang Z, Zheng Y, Li K, Wang Y, Wang Y, Wang H, Wang Y, Jiang L, Zhu X, Wei Y (2021). Chem Eng Sci. https://doi.org/10.1016/j.ces.2020.116085

Kholod N, Evans M, Pilcher RC, Roshchanka V, Ruiz F, Cote M, Collings R (2020) J Clean Prod 256:120489. https://doi.org/10.1016/j.jclepro.2020.120489

Hu W, Lan J, Guo Y, Cao X-M, Hu P (2016) ACS Catal 6:5508–5519. https://doi.org/10.1021/acscatal.6b01080

Murata K, Kosuge D, Ohyama J, Mahara Y, Yamamoto Y, Arai S, Satsuma A (2019) ACS Catal 10:1381–1387. https://doi.org/10.1021/acscatal.9b04524

Zheng Y, Wang C, Li J, Zhong F, Xiao Y, Jiang L (2020) ACS Appl Nano Mater 3:9470–9479. https://doi.org/10.1021/acsanm.0c02075

Wang Z, Lin J, Xu H, Zheng Y, Xiao Y, Zheng Y (2021) ACS Appl Nano Mater 4:11920–11930. https://doi.org/10.1021/acsanm.1c02487

Dai Q, Zhu Q, Lou Y, Wang X (2018) J Catal 357:29–40. https://doi.org/10.1016/j.jcat.2017.09.022

Ding Y, Wang S, Zhang L, Lv L, Gao Y, Wang S (2020). Catal Commun. https://doi.org/10.1016/j.catcom.2020.106084

Qu P, Wang S, Hu W, Wu Y, Chen J, Zhang G, Shen P, Chen Y, Zhong L (2020). Catal Commun. https://doi.org/10.1016/j.catcom.2019.105900

Feng X, Jiang L, Li D, Tian S, Zhu X, Wang H, He C, Li K (2022). J Energy Chem. https://doi.org/10.1016/j.jechem.2022.08.001

Bhavani AG, Kim WY, Lee JS (2013) ACS Catal 3:1537–1544. https://doi.org/10.1021/cs400245m

Zhang J, Tan D, Meng Q, Weng X, Wu Z (2015) Appl Catal B 172–173:18–26. https://doi.org/10.1016/j.apcatb.2015.02.006

Zhu X, Li K, Neal L, Li F (2018) ACS Catal 8:8213–8236. https://doi.org/10.1021/acscatal.8b01973

Zhao K, He F, Huang Z, Wei G, Zheng A, Li H, Zhao Z (2017) Korean J Chem Eng 34:1651–1660. https://doi.org/10.1007/s11814-016-0329-6

Wang Y, Ren J, Wang Y, Zhang F, Liu X, Guo Y, Lu G (2008) J Phys Chem C 112:15293–15298. https://doi.org/10.1021/jp8048394

Jiang L, Li D, Deng G, Lu C, Huang L, Li Z, Xu H, Zhu X, Wang H, Li K (2023). Chem Eng J. https://doi.org/10.1016/j.cej.2022.141054

Wang W, Zhou W, Li W, Xiong X, Wang Y, Cheng K, Kang J, Zhang Q, Wang Y (2020). Appl Catal B. https://doi.org/10.1016/j.apcatb.2020.119142

Lee YN, Lago RM, Fierro JLG, Cortés V, Sapiña F, Martínez E (2001) Appl Catal A 207:17–24. https://doi.org/10.1016/S0926-860X(00)00610-4

Lisi L, Bagnasco G, Ciambelli P, De Rossi S, Porta P, Russo G, Turco M (1999) J Solid State Chem 146:176–183. https://doi.org/10.1006/jssc.1999.8327

Glisenti A, Pacella M, Guiotto M, Natile M, Canu P (2016) Appl Catal B 180:94–105. https://doi.org/10.1016/j.apcatb.2015.06.017

Kucharczyk B, Tylus W (2004) Catal Today 90:121–126. https://doi.org/10.1016/j.cattod.2004.04.016

Bhatt MD, Lee JY (2020) Energy Fuels 34:6634–6695. https://doi.org/10.1021/acs.energyfuels.0c00953

de Lira LDC, Lemos IP, Gomes RS, Rodrigues LMTS, Fréty RT, Resini C, Junior RBS, Brandão ST (2022). Catal Lett. https://doi.org/10.1007/s10562-022-04127-8

Lee M, Lim HS, Kim Y, Lee JW (2020) Energy Convers Manag 207:112507. https://doi.org/10.1016/j.enconman.2020.112507

Dong C, Sun H, Zhou Y, Zhan H, Wang G, Liu W, Bi S, Ma B (2022) J Environ Chem Eng 10:107718. https://doi.org/10.1016/j.jece.2022.107718

Natile MM, Ugel E, Maccato C, Glisenti A (2007) Appl Catal B 72:351–362. https://doi.org/10.1016/j.apcatb.2006.11.011

Xie X, Ni C, Lin Z, Wu D, Sun X, Zhang Y, Wang B, Du W (2020). Chem Eng J. https://doi.org/10.1016/j.cej.2020.125205

Zhao Y, Gu Z, Li D, Yuan J, Jiang L, Xu H, Lu C, Deng G, Li M, Xiao W, Li K (2022). Fuel. https://doi.org/10.1016/j.fuel.2022.124399

Yuan K, Wang Y, Li K, Zhu X, Wang H, Jiang L, Wei Y, Shan S, Zheng Y (2022) ACS Appl Mater Interfaces 14:39004–39013. https://doi.org/10.1021/acsami.2c12700

Chen J, Shi W, Zhang X, Arandiyan H, Li D, Li J (2011) Environ Sci Technol 45:8491–8497. https://doi.org/10.1021/es201659h

Ao R, Ma L, Guo Z, Liu H, Yang J, Yin X, Pan Q (2021) Fuel 305:121617. https://doi.org/10.1016/j.fuel.2021.121617

Wang F, Gu W, Chen J, Huang Q, Han M, Wang G, Ji G (2022) J Mater Sci Technol 105:92–100. https://doi.org/10.1016/j.jmst.2021.06.058

Lim HS, Lee M, Kang D, Lee JW (2018) Int J Hydrogen Energy 43:20580–20590. https://doi.org/10.1016/j.ijhydene.2018.09.067

Zhang C, Wang C, Hua W, Guo Y, Lu G, Gil S, Giroir-Fendler A (2016) Appl Catal B 186:173–183. https://doi.org/10.1016/j.apcatb.2015.12.052

Wang Y, Aghamohammadi S, Li D, Li K, Farrauto R (2019) Appl Catal B 244:438–447. https://doi.org/10.1016/j.apcatb.2018.11.066

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Project Nos. 22268026, 22002125 and 21706108), the Yunnan Fundamental Research Projects (Nos. 202301AT070438, 2018FD032).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cheng, Z., Wang, Y., Li, K. et al. Enhanced Redox Ability of LaCoO3 Catalysts by Cu Doping in Methane Combustion. Catal Lett 154, 1126–1133 (2024). https://doi.org/10.1007/s10562-023-04366-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-023-04366-3