Abstract

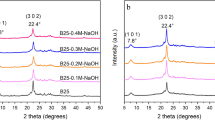

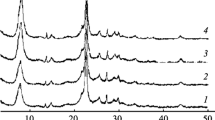

Trioxane (TOX), which is usually produced from formaldehyde catalyzed by acid-catalysts, is an important polymerizing monomer to produce high-performance plastics polyoxymethylene polymers (POMs). In order to reduce the separation cost and increase the catalytic activity, hierarchical Beta zeolites with different pore size were synthesized by PDDA and used for TOX produce from formaldehyde in this work. Hierarchical Beta zeolites’ average pore size increased with the increasing of PDDAs’ molecular weight. Compare to conventional Beta zeolite, it exhibited a higher catalytic performance with 95.13% selectivity and 2118 g/kg/h space–time yield of TOX due to its excellent diffusion performance from extra mesopore. The HCHO conversion and space–time yield of TOX increase first and then decrease with the pore size increasing. Further research showed that the decrease of catalytic activity is mainly due to the increase of extra-framework Al percent. This work illustrates the influence of both pore size and extra-framework Al content in hierarchical Beta zeolites for TOX produce from formaldehyde reaction.

Graphical Abstract

Similar content being viewed by others

References

Kurokawa M, Uchiyama Y, Nagai S (2000) Tribological properties and gear performance of polyoxymethylene composites. J Trib 122:809–814

Liu H, Wang J, Jiang P, Yan F (2020) Durability of fiber-reinforced polyoxymethylene composites under the high hydrostatic pressure in the deep sea. J Appl Polym Sci 137:48686

Penick KJ, Solchaga LA, Berilla JA, Welter JF (2005) Performance of polyoxymethylene plastic (POM) as a component of a tissue engineering bioreactor. J Biomed Mater Res A 75:168–174

Kuciel S, Bazan P, Liber-Kneć A, Gądek-Moszczak A (2019) Physico-mechanical properties of the poly (oxymethylene) composites reinforced with glass fibers under dynamical loading. Polymers 11:2064

Siengchin S, Karger-Kocsis J, Psarras G, Thomann R (2008) Polyoxymethylene/polyurethane/alumina ternary composites: structure, mechanical, thermal and dielectric properties. J Appl Polym Sci 110:1613–1623

Wang J, Hu K, Xu Y, Hu X (2008) Structural, thermal, and tribological properties of intercalated polyoxymethylene/molybdenum disulfide nanocomposites. J Appl Polym Sci 110:91–96

Masamoto J, Nagahara H, Yokoyama T, Fujikawa R, Tanaka T, Yamaguchi T (1999) Ultrahigh molecular weight polyoxymethylene from aqueous formaldehyde solution. Chem Lett 28:1131–1132

Wang D, Zhu G, Li Z, Xia C (2019) Polyoxymethylene dimethyl ethers as clean diesel additives: fuel freezing and prediction. Fuel 237:833–839

Edward FC (1942) Proparation of alpha trioxymethylene. Du pont company, US 2304080

Yin L, Hu Y, Zhang X, Qi J, Ma W (2015) The salt effect on the yields of trioxane in reaction solution and in distillate. Rsc Adv 5:37697–37702

Qi J, Hu Y, Gao Y, Ma W, Mo S, Yang Z, Zhang X, Yin L (2017) Salt effects on extraction of trioxane from aqueous formaldehyde solutions. Fluid Phase Equilibr 434:1–6

Yin L-Y, Hu Y-F, Wang H-Y (2016) The remarkable effect of organic salts on 1, 3, 5-trioxane synthesis. Petrol Sci 13:770–775

Ma W, Hu Y, Qi J, Wei L, Zhang X, Yang Z, Jiang S (2017) Acid-catalyzed synthesis of trioxane in aprotic media. Ind Eng Chem Res 56:6910–6915

Xia C, Tang Z, Chen J, Zhang X, Li Z, Guo E (2007) Lanzhou Institute of Chemical Physics CAS, US 7244854 B2

Chen J, Song H, Xia C, Tang Z, Zhang X, Li Z, Guo E (2008) Lanzhou Institute of Chemical Physics CAS, US 0293954 A1

Chen J, Song H, Xia C, Tang Z, Zhang X, Li Z, Guo E (2009) Lanzhou Institute of Chemical Physics CAS, US 7598402 B2

Zhao Y, Hu Y, Qi J, Ma W (2016) Brønsted-acidic ionic liquids as catalysts for synthesizing trioxane. Chin J Chem Eng 24:1392–1398

Matsuzaki Y (1984) Process for preparating trioxane. Asahi Kasei Industrial Co., LTD, JP 59134789

Morishita H (1999) Process for preduction of trioxane. Asahi Kasei Kogyo Kabushiki Kaisha, US 5962702

Emig G, Kern F, Warnecke H-J (1994) Vapour-phase trimerisation of formaldehyde to trioxane catalyzed by 1-vanado-11-molybdophosphoric acid: a reaction rate with an unusual pressure depend. Appl Catal A-Gen 118:17–20

Kern F, Emig G (1997) Vapour-phase trimerization of formaldehyde to trioxane catalysed by 1-vanado-11-molybdophosphoric acid. Appl Catal A-Gen 150:143–151

Emig G, Erlangen, Kern F (1996) Process for the preparation of trioxane. Hoechst Aktiengesellschaft, US 5508448

Hoffmockel M, Emig G (2000) Process for preparing trioxane. Vogelherd Erlangen, US 6124480

Masamoto J, Hamanaka K, Yoshida K, Nagahara H, Kagawa K, Iwaisako T, Komaki H (2000) Synthesis of trioxane using heteropolyacids as catalyst. Angew Chem Int Edit 39:2102–2104

Ishida H, Nakagawa Y (1989) Asahi Kasei Industrial Co., LTD, JP2571698B2

Ishida H, Kanji A (1996) The synthetic reaction of trioxane from formalin on the zeolite catalysts. Nippon Kagaku Kaishi 3:290–297

Ye Y, Yao M, Chen H, Zhang X (2020) Influence of silanol defects of ZSM-5 zeolites on trioxane synthesis from formaldehyde. Catal Lett 150:1445–1453

Ye YL, FU M, Chen H L, Zhang X M, (2020) Effect of acidity on the catalytic performance of ZSM-5 zeolites in the synthesis of trioxane from formaldehyde. J Fuel Chem Tech 48:311–320

Balashov A, Krasnov V, Danov S, Chernov AY, Sulimov A (2001) Formation of cyclic oligomers in concentrated aqueous solutions of formaldehyde. J Struct Chem 42:398–403

Janssen A, Schmidt I, Jacobsen C, Koster A, De Jong K (2003) Exploratory study of mesopore templating with carbon during zeolite synthesis. Micropor Mesopor Mat 65:59–75

Chen H, Wydra J, Zhang X, Lee P-S, Wang Z, Fan W, Tsapatsis M (2011) Hydrothermal synthesis of zeolites with three-dimensionally ordered mesoporous-imprinted structure. J Am Chem Soc 133:12390–12393

Fan W, Snyder MA, Kumar S, Lee P-S, Yoo WC, McCormick AV, Lee Penn R, Stein A, Tsapatsis M (2008) Hierarchical nanofabrication of microporous crystals with ordered mesoporosity. Nat mater 7:984–991

Zhao J, Hua Z, Liu Z, Li Y, Guo L, Bu W, Cui X, Ruan M, Chen H, Shi J (2009) Direct fabrication of mesoporous zeolite with a hollow capsular structure. Chem commun 48:7578–7580

Zhu J, Zhu Y, Zhu L, Rigutto M, van der Made A, Yang C, Pan S, Wang L, Zhu L, Jin Y (2014) Highly mesoporous single-crystalline zeolite beta synthesized using a nonsurfactant cationic polymer as a dual-function template. J Am Chem Soc 136:2503–2510

Zhu Y, Hua Z, Zhou J, Wang L, Zhao J, Gong Y, Wu W, Ruan M, Shi J (2011) Hierarchical mesoporous zeolites: direct self-assembly synthesis in a conventional surfactant solution by kinetic control over the zeolite seed formation. Chem–A Eur J 17(51):14618–14627

Yuan Y, Tian P, Yang M, Fan D, Wang L, Xu S, Wang C, Wang D, Yang Y, Liu Z (2015) Synthesis of hierarchical beta zeolite by using a bifunctional cationic polymer and the improved catalytic performance. RSC Adv 5:9852–9860

Camblor M, Mifsud A, Pérez-Pariente J (1991) Influence of the synthesis conditions on the crystallization of zeolite Beta. Zeolites 11:792–797

Ravi M, Sushkevich VL, van Bokhoven JA (2020) Towards a better understanding of Lewis acidic aluminium in zeolites. Nature Mater 19:1047–1056

Funding

This work was funded by CAS” Light of West China” Program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Duan, Z., Wei, R. et al. Production of Trioxane from Formaldehyde via Hierarchical Beta Zeolite Synthesized Using a Cationic Polymer. Catal Lett 153, 3837–3845 (2023). https://doi.org/10.1007/s10562-022-04265-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-022-04265-z