Abstract

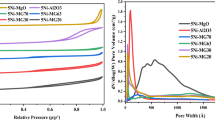

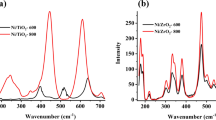

The reaction of methane decomposition is an endothermic process that produces hydrogen without any impurities as a gas product and carbon nanotubes/carbon nanofibers as a solid product. In this study, NiO–MgO catalysts with different nickel loadings (20, 30, 40, and 50 wt. %) were synthesized using the mechanochemical method. The Physicochemical features of the synthesized catalysts were characterized by various methods such as BET, XRD, SEM, TPO, and H2-TPR. The prepared samples were tested in the methane decomposition process at various temperatures under the GHSV value of 48,000 ml/(gcat h). Among the prepared samples, the 50wt.%NiO–MgO exhibited the best activity (40% methane conversion at 575 °C) in this process due to its higher concentration of active metal and better catalyst reducibility. Also, the effect of different parameters such as feed ratio, GHSV, and calcination temperature was studied on the activity of this catalyst. The results showed that with the increase of GHSV and feed ratio, the methane conversion decreased due to the lesser contact time and diminishing the proportion of accessible active sites per methane entrance molecules. Moreover, the results showed that with the rise of calcination temperature from 500 to 700 °C, the methane conversion decreased due to the sintering of nickel particles. The results also showed that the addition of 15 wt.% Cr2O3 to the catalyst formulation improved the catalytic performance and lifetime in the thermocatalytic decomposition of methane due to the higher reducibility and dispersion of the active species on the catalyst surface.

Graphical Abstract

Similar content being viewed by others

References

Escobar C, Perez-Lopez OW (2014) Hydrogen production by methane decomposition over Cu-Co-Al mixed oxides activated under reaction conditions. Catal Letters 144(5):796–804. https://doi.org/10.1007/s10562-014-1234-4

Jokar R, Alavi SM, Rezaei M, Akbari E (2021) Catalytic performance of copper oxide supported α-MnO2 nanowires for the CO preferential oxidation in H2-rich stream. Int J Hydrogen Energy 46(64):32503–32513. https://doi.org/10.1016/j.ijhydene.2021.07.108

Tamimi K, Alavi SM, Rezaei M, Akbari E (2021) Preparation of the Mn-Promoted NiO–Al2O3 nanocatalysts for low temperature CO2 methanation. J Energy Inst 99(June):48–58. https://doi.org/10.1016/j.joei.2021.08.008

Dang C, Long J, Li H, Cai W, Yu H (2021) Pd-promoted Ni-Ca-Al bi-functional catalyst for integrated sorption-enhanced steam reforming of glycerol and methane reforming of carbonate. Chem Eng Sci 230:116226. https://doi.org/10.1016/j.ces.2020.116226

Varbar M, Alavi SM, Rezaei M, Akbari E (2022) Cobalt promoted Ni/MgAl2O4 catalyst in lean methane catalytic oxidation. Res Chem Intermed 48:1129–1150. https://doi.org/10.1007/s11164-021-04626-0

Wang D, Li W, Liu J, Gao Z, Xu G, Cui Y (2020) Methane thermocatalytic decomposition to COx-free hydrogen and carbon nanomaterials over Ni–Mn–Ru/Al2O3 catalysts. Int J Hydrogen Energy 45(55):30431–30442. https://doi.org/10.1016/j.ijhydene.2020.08.039

Echegoyen Y, Suelves I, Lázaro MJ, Moliner R, Palacios JM (2007) Hydrogen production by thermocatalytic decomposition of methane over Ni-Al and Ni-Cu-Al catalysts: effect of calcination temperature. J Power Sources 169(1):150–157. https://doi.org/10.1016/j.jpowsour.2007.01.058

Kim MH et al (2003) Hydrogen production by catalytic decomposition of methane over activated carbons: deactivation study. Korean J Chem Eng 20(5):835–839. https://doi.org/10.1007/BF02697284

Liu Q, Wu P, He J, Liu C, Jiang W (2020) Catalytic decomposition of methane by two-step cascade catalytic process: simultaneous production of hydrogen and carbon nanotubes. Chem Eng Res Des 163:96–106. https://doi.org/10.1016/j.cherd.2020.08.029

Rastegarpanah A, Rezaei M, Meshkani F, Dai H, Arandiyan H (2018) Thermocatalytic decomposition of methane over mesoporous Ni/xMgO·Al2O3 nanocatalysts. Int J Hydrogen Energy 43(32):15112–15123. https://doi.org/10.1016/j.ijhydene.2018.06.057

García-Sancho C, Guil-López R, Pascual L, Maireles-Torres P, Navarro RM, Fierro JLG (2017) Optimization of nickel loading of mixed oxide catalyst ex-hydrotalcite for H2 production by methane decomposition. Appl Catal A Gen 548(April):71–82. https://doi.org/10.1016/j.apcata.2017.07.038

Srilatha K, Bhagawan D, Shiva Kumar S, Himabindu V (2017) “Sustainable fuel production by thermocatalytic decomposition of methane – a review”, South African. J Chem Eng 24:156–167. https://doi.org/10.1016/j.sajce.2017.10.002

Gadkari S, Fidalgo B, Gu S (2017) Numerical analysis of microwave assisted thermocatalytic decomposition of methane. Int J Hydrogen Energy 42(7):4061–4068. https://doi.org/10.1016/j.ijhydene.2016.09.126

Bayat N, Rezaei M, Meshkani F (2016) Hydrogen and carbon nanofibers synthesis by methane decomposition over Ni-Pd/Al2O3 catalyst. Int J Hydrogen Energy 41(12):5494–5503. https://doi.org/10.1016/j.ijhydene.2016.01.134

Muradov N, Smith F, A. T-Raissi, (2005) Catalytic activity of carbons for methane decomposition reaction. Catal Today 102–103:225–233. https://doi.org/10.1016/j.cattod.2005.02.018

Azizzadeh Fard A, Arvaneh R, Alavi SM, Bazyari A, Valaei A (2019) Propane steam reforming over promoted Ni–Ce/MgAl2O4 catalysts: effects of Ce promoter on the catalyst performance using developed CCD model. Int J Hydrogen Energy 44(39):21607–21622. https://doi.org/10.1016/j.ijhydene.2019.06.100

Hadian M, Buist KA, Bos ANR, Kuipers JAM (2021) Single catalyst particle growth modeling in thermocatalytic decomposition of methane. Chem Eng J 421(P1):129759. https://doi.org/10.1016/j.cej.2021.129759

Kazemi S, Alavi SM, Rezaei M (2022) Hydrogen production from COx Free thermocatalytic decomposition of methane over the mesoporous iron aluminate spinel (FeAl2O4) nanopowder supported nickel catalysts. Int J Hydrogen Energy 47:18370–18383. https://doi.org/10.1016/j.ijhydene.2022.04.050

Srilatha K, Bhagawan D, Srinivasulu D, Himabindu V (2018) Comparison study between Ni/TiO2 and Ni/flame synthesized TiO2 catalysts for hydrogen production using thermocatalytic decomposition of methane. South African J Chem Eng 25:91–97. https://doi.org/10.1016/j.sajce.2018.02.003

Hermes NA, Lansarin MA, Perez-Lopez OW (2011) Catalytic decomposition of methane over M-Co-Al catalysts (M = Mg, Ni, Zn, Cu). Catal Lett 141(7):1018–1025. https://doi.org/10.1007/s10562-011-0611-5

Zhang X et al (2018) CO2 mitigation costs of catalytic methane decomposition. Energy 151:826–838. https://doi.org/10.1016/j.energy.2018.03.132

Abbas HF, Wan Daud WMA (2009) Thermocatalytic decomposition of methane using palm shell based activated carbon: kinetic and deactivation studies. Fuel Process Technol 90(9):1167–1174. https://doi.org/10.1016/j.fuproc.2009.05.024

Pudukudy M, Yaakob Z, Akmal ZS (2015) Direct decomposition of methane over Pd promoted Ni/SBA-15 catalysts. Appl Surf Sci 353:127–136. https://doi.org/10.1016/j.apsusc.2015.06.073

García-Sancho C, Guil-López R, Sebastián-López A, Navarro RM, Fierro JLG (2018) Hydrogen production by methane decomposition: a comparative study of supported and bulk ex-hydrotalcite mixed oxide catalysts with Ni, Mg and Al. Int J Hydrogen Energy 43(20):9607–9621. https://doi.org/10.1016/j.ijhydene.2018.04.021

Ashik UPM, Daud WMAW (2016) Stabilization of Ni, Fe, and Co nanoparticles through modified Stöber method to obtain excellent catalytic performance: preparation, characterization, and catalytic activity for methane decomposition. J Taiwan Inst Chem Eng 61:247–260. https://doi.org/10.1016/j.jtice.2015.12.019

Venugopal A et al (2007) Hydrogen production by catalytic decomposition of methane over Ni / SiO2. Int J Hydrogen Energy 32(12):1782–1788. https://doi.org/10.1016/j.ijhydene.2007.01.007

Awad A, Masiran N, Abdus Salam M, Vo DVN, Abdullah B (2019) Non-oxidative decomposition of methane/methanol mixture over mesoporous Ni-Cu/Al2O3 Co-doped catalysts. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2018.04.233

Pudukudy M, Yaakob Z, Takriff MS (2016) Methane decomposition into COx free hydrogen and multiwalled carbon nanotubes over ceria, zirconia and lanthana supported nickel catalysts prepared via a facile solid state citrate fusion method. Energy Convers Manag 126:302–315. https://doi.org/10.1016/j.enconman.2016.08.006

Hu X et al (2020) Molten salt-promoted Ni–Fe/Al2O3 catalyst for methane decomposition. Int J Hydrogen Energy 45(7):4244–4253. https://doi.org/10.1016/j.ijhydene.2019.11.209

Liu F et al (2016) Application of chemical looping process for continuous high purity hydrogen production by methane thermocatalytic decomposition. Int J Hydrogen Energy 41(8):4592–4602. https://doi.org/10.1016/j.ijhydene.2016.01.023

Ashik UPM, Wan Daud WMA, Abbas HF (2015) Production of greenhouse gas free hydrogen by thermocatalytic decomposition of methane - a review. Renew Sustain Energy Rev 44:221–256. https://doi.org/10.1016/j.rser.2014.12.025

Muradov N, Smith F, Bockerman G, Scammon K (2009) Thermocatalytic decomposition of natural gas over plasma-generated carbon aerosols for sustainable production of hydrogen and carbon. Appl Catal A Gen 365(2):292–300. https://doi.org/10.1016/j.apcata.2009.06.031

Asai K, Takane K, Nagayasu Y, Iwamoto S, Yagasaki E, Inoue M (2008) Decomposition of methane in the presence of carbon dioxide over Ni catalysts. Chem Eng Sci 63(20):5083–5088. https://doi.org/10.1016/j.ces.2007.08.012

Bai Z, Chen H, Li W, Li B (2006) Hydrogen production by methane decomposition over coal char. Int J Hydrogen Energy 31(7):899–905. https://doi.org/10.1016/j.ijhydene.2005.08.001

Rastegarpanah A, Meshkani F, Rezaei M (2017) Thermocatalytic decomposition of methane over mesoporous nanocrystalline promoted Ni/MgO·Al2O3 catalysts. Int J Hydrogen Energy 42(26):16476–16488. https://doi.org/10.1016/j.ijhydene.2017.05.044

Cunha AF, Órfão JJM, Figueiredo JL (2008) Catalytic decomposition of methane on Raney-type catalysts. Appl Catal A Gen 348(1):103–112. https://doi.org/10.1016/j.apcata.2008.06.028

Rastegarpanah A et al (2019) Mesoporous Ni/MeO x (Me = Al, Mg, Ti, and Si): highly efficient catalysts in the decomposition of methane for hydrogen production. Appl Surf Sci 478(February):581–593. https://doi.org/10.1016/j.apsusc.2019.02.009

Barzegari F, Kazemeini M, Rezaei M, Farhadi F, Keshavarz A (2020) Propane steam reforming on mesoporous NiO–MgO–SiO2 catalysts for syngas production: Effect of the MgO/SiO2 molar ratio. Int J Hydrogen Energy 45(46):24840–24858. https://doi.org/10.1016/j.ijhydene.2020.06.281

Akbari E, Alavi SM, Rezaei M, Larimi A (2021) Barium promoted manganese oxide catalysts in low-temperature methane catalytic combustion. Int J Hydrogen Energy 46(7):5181–5196. https://doi.org/10.1016/j.ijhydene.2020.11.016

Guo B et al (2019) Mechanochemical synthesis of multi-site electrocatalysts as bifunctional zinc-air battery electrodes. J Mater Chem A 7(33):19355–19363. https://doi.org/10.1039/c9ta06411g

Ruckenstein E, Hu YH (1998) Combination of CO2 reforming and partial oxidation of methane over NiO/MgO solid solution catalysts. Ind Eng Chem Res 37(5):1744–1747. https://doi.org/10.1021/ie9707883

Rheinheimer W, Lowing D, Blendell JE (2020) Grain growth in Nio–MgO and its dependence on faceting and the equilibrium crystal shape. Scr Mater 178:236–239. https://doi.org/10.1016/j.scriptamat.2019.11.034

Jiang S, Lu Y, Wang S, Zhao Y, Ma X (2017) Insight into the reaction mechanism of CO 2 activation for CH 4 reforming over NiO-MgO: a combination of DRIFTS and DFT study. Appl Surf Sci 416:59–68. https://doi.org/10.1016/j.apsusc.2017.04.142

Park YS et al (2018) Fabrication of a regenerable Ni supported NiO–MgO catalyst for methane steam reforming by exsolution. J Power Sources 397(July):318–324. https://doi.org/10.1016/j.jpowsour.2018.07.025

Rastegarpanah A et al (2019) 2018 “Influence of group VIB metals on activity of the Ni/MgO catalysts for methane decomposition.” Appl Catal B Environ 248:515–525. https://doi.org/10.1016/j.apcatb.2019.01.067

Cunha AF, Órfão JJM, Figueiredo JL (2009) Methane decomposition on Ni-Cu alloyed Raney-type catalysts. Int J Hydrogen Energy 34(11):4763–4772. https://doi.org/10.1016/j.ijhydene.2009.03.040

Akbari E, Alavi SM, Rezaei M, Larimi AS (2022) Preparation and evaluation of A/BaO-MnOx (A: Rh, Pt, Pd, Ru) in lean methane catalytic combustion at low temperature. Int J Energy Res 46:6292–6313. https://doi.org/10.1002/er.7567

Liu X, Wu J (2019) Coupling interface constructions of NiO–Cr2O3 heterostructures for efficient electrocatalytic oxygen evolution. Electrochim Acta 320:134577. https://doi.org/10.1016/j.electacta.2019.134577

Choi BK, Park YH, Moon DJ, Park NC, Kim YC (2015) Effect of bimetallic Ni–Cr catalysts for steam-CO2 reforming of methane at high pressure. J Nanosci Nanotechnol 15(7):5259–5263. https://doi.org/10.1166/jnn.2015.10404

Liang W et al (2020) NiMgAlMo catalyst derived from a guest-host MoO42- mediated layered double hydroxide: high performance for the methane decomposition reaction. Appl Catal A Gen 597:117551. https://doi.org/10.1016/j.apcata.2020.1175

Chen Q, Lua AC (2021) Synthesis of electroless Ni catalyst supported on SBA-15 for hydrogen and carbon production by catalytic decomposition of methane. Int J Energy Res 45(2):2810–2823. https://doi.org/10.1002/er.5975

Gubanov MA et al (2020) Methane decomposition nickel catalysts based on structured supports. Pet Chem 60(9):1043–1051. https://doi.org/10.1134/S096554412009011X

Karaismailoglu M, Figen HE, Baykara SZ (2019) Hydrogen production by catalytic methane decomposition over yttria doped nickel based catalysts. Int J Hydrogen Energy 44(20):9922–9929. https://doi.org/10.1016/j.ijhydene.2018.12.214

Acknowledgements

The authors gratefully acknowledge the financial support received from the Iran National Science Foundation (INSF) under the grant number of 97017638.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pourdelan, H., Alavi, S.M., Rezaei, M. et al. Thermocatalytic Decomposition of Methane Over NiO–MgO Catalysts Synthesized by the Mechanochemical Method. Catal Lett 153, 3159–3173 (2023). https://doi.org/10.1007/s10562-022-04175-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-022-04175-0