Abstract

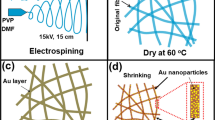

As one of extensively used photocatalysts, zinc oxide nanoparticles (ZnO NPs) can generate free radicals under proper light irradiation, thereby achieving excellent antibacterial performance. However, the requirement of using light activation has limited its application to wider fields. In addition, nano-copper (Cu NPs) have gradually attracted the attention of researchers due to their excellent antibacterial properties. However, the high surface activity of nanoparticles makes them easy to agglomerate, and Cu NPs are easily oxidized, which affect the antibacterial activity. By synthesizing Cu–ZnO composite nanoparticles and loading the particles onto low melting-point polyethylene terephthalate (LMPET) fibers, we have developed a novel catalytic fiber (Cu–ZnO@LMPET) that can generate active species without needing light. It was found that Cu–ZnO@LMPET fibers with the copper content of 5 wt% (vs. ZnO NPs) or above could achieve 99% antibacterial effects on S. aureus and E. coli under dark conditions. Moreover, the antibacterial rates against E. coli and S. aureus could still be larger than 97 and 98%, respectively, even if the fibers were washed 50 times. In-vitro biocompatibility assessment also displayed that the as-prepared fibers had superb cytocompatibility. These results indicate that our developed fibers have highly efficient antibacterial properties, good washing resistance and high stability. Thus, our work has shed new light on the use of Cu–ZnO NPs for antibacterial purposes.

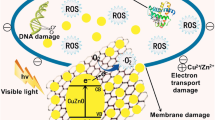

Graphical Abstract

Similar content being viewed by others

References

Hendaus MA, Jomha FA (2021) J Biomol Struct Dyn 39:4185–4191

Ben YJ, Fu CX, Hu M, Liu L, Wong MH, Zheng CM (2019) Environ Res 169:483–493

Gupta A, Mumtaz S, Li CH, Hussain I, Rotello VM (2019) Chem Soc Rev 48:415–427

Wang Y, Yang YN, Shi YR, Song H, Yu CZ (2020) Adv Mater 32:1904106

Saidin S, Jumat MA, Mohd Amin NAA, Saleh Al-Hammadi AS (2021) Mater Sci Eng: C 118:111382

Qais FA, Shafiq A, Khan HM, Husain FM, Khan RA, Alenazi B, Alsalme A, Ahmad I (2019) Bioinorg Chem Appl 2019:4649506

Zhang X, Zhang G, Chai M, Yao X, Chen W, Chu PK (2021) Bioact Mater 6:12–25

Gurunathan S (2019) Arab J Chem 12:168–180

Svetlichnyi V, Shabalina A, Lapin I, Goncharova D, Nemoykina A (2016) Appl Surf Sci 372:20–29

Liu J, Wang Y, Ma J, Peng Y, Wang A (2019) J Alloy Compd 783:898–918

Jiang J, Pi J, Cai J (2018) Bioinorg Chem Appl 2018:1062562

Panchal P, Paul DR, Sharma A, Choudhary P, Meena P, Nehra SP (2020) J Colloid Interf Sci 563:370–380

Huo S, Ding S, Zhao C, Wang C, Yu F, Fang J, Yang Y (2020) Catal Lett 151:1937–1947

Van Thuan D, Khoa NT, Kim S-W, Chung JS, Hur SH, Kim EJ, Hahn SH, Wang M (2017) Catal Lett 147:2440–2447

Xi J, Wei G, An L, Xu Z, Xu Z, Fan L, Gao L (2019) Nano Lett 19:7645–7654

Jessop IA, Perez YP, Jachura A, Nunez H, Saldias C, Isaacs M, Tundidor-Camba A, Terraza CA, Araya-Duran I, Camarada MB, Carcamo-Vega JJ (2021) Polym 13:401

Phan DN, Dorjjugder N, Saito Y, Khan MQ, Ullah A, Bie X, Taguchi G, Kim I-S (2020) Mater Today Commun 25:101377

Powar NS, Patel VJ, Pagare PK, Pandav RS (2019) Chem Methodol 3:457–480

Wang L, Hu C, Shao L (2017) Int J Nanomed 12:1227–1249

Naradala J, Allam A, Tumu VR, Rajaboina RK (2022) Biointerface Res App 12:1230–1236

Zhang Y, Pan T, Yang Z (2020) Chem Eng J 389:124433

Arslan M, Günay K (2018) Int J Polym Mater Po 68:811–818

Xu S, Lu W, Chen S, Xu Z, Xu T, Sharma VK, Chen W (2019) Chem Eng J 375:121949

Arif M, Monga S, Sanger A, Vilarinho PM, Singh A (2018) Vacuum 155:662–666

He M, Lu L, Zhang J, Li D (2015) Sci Bull 60:227–234

Jiménez-Hernández L, Estévez-Hernández O, Hernández-Sánchez M, Díaz JA, Farías- Sánchez M, Reguera E (2016) Colloid Surface A 489:351–359

Norouzi A, Nezamzadeh-Ejhieh A, Fazaeli R (2021) Mat Sci Semicon Proc 122:105495

Pillai AM, Sivasankarapillai VS, Rahdar A, Joseph J, Sadeghfar F, Anuf AR, Rajesh K, Kyzas GZ (2020) J Mol Struct 1211:128107

Manjari G, Saran S, Devipriya SP, Rao AVB (2018) Catal Lett 148:2561–2571

Pimpliskar PV, Motekar SC, Umarji GG, Lee W, Arbuj SS (2019) Photoch Photobio Sci 18:1503–1511

Xiao S, Zhao L, Lian J (2013) Catal Lett 144:347–354

Kumar R, Umar A, Kumar G, Nalwa HS (2017) Ceram Int 43:3940–3961

Wang P, Yang L, Li J, Sadeh B (2020) Catal Lett 150:1985–1992

Ramesh S, Vetrivel S, Suresh P, Kaviarasan V (2020) Mater Today: Proc 33:2626–2630

Huang Z, Bi L, Zhang Z, Han Y (2012) Mol Med Rep 6:709–715

Chen CH (2010) J Appl Polym Sci 87:2004–2010

Saravanan R, Thirumal E, Gupta VK, Narayanan V, Stephen A (2013) J Mol Liq 177:394–401

Al-Gaashani R, Radiman S, Daud AR, Tabet N, Al-Douri Y (2013) Ceram Int 39:2283–2292

Wang J, Wang Z, Huang B, Ma Y, Liu Y, Qin X, Zhang X, Dai Y (2012) Acs Appl Mater Inter 4:4024–4030

Devaraj M, Saravanan R, Deivasigamani R, Gupta VK, Gracia F, Jayadevan S (2016) J Mol Liq 221:930–941

Tahir D, Tougaard S (2012) J Phys Condens Matter 24(13):135005

Lu L, Hu S, Lee H-I, Wöll C, Fischer RA (2006) J Nanopart Res 9:491–496

Lennox AJJ, Bartels P, Pohl M-M, Junge H, Beller M (2016) J Catal 340:177–183

Li X, Ji X, Chen K, Ullah MW, Yuan X, Lei Z, Cao J, Xiao J, Yang G (2020) Biomater Sci 8:2797–2813

Kunliang L, Zhicheng J, Xiaolong H, Dan Y, Yu Z, Haidong Z, Gaojun T, Fei X (2020) Int J Biol Macromol 142:866–878

Du L, Huang Y, Zhang Q, Zhou Y, Huang J, Yan L, Yu Z, Qin A, Yang H, Chen M, Liang L, Bian B, Li X, Fu J (2019) Acta Biomater 88:370–382

He M, Lu L, Zhang J, Li D (2015) J Nanosci Nanotechno 15:6435–6443

Agnihotri S, Mukherji S, Mukherji S (2013) Nanoscale 5:7328–7340

Herman A, Herman AP (2014) J Nanosci Nanotechno 14:946–957

Wang X, Lu W, Zhao Z, Zhong H, Zhu Z, Chen W (2020) Chem Eng J 400:125872

Meng S, Wu H, Cui Y, Zheng X, Wang H, Chen S, Wang Y, Fu X (2020) Appl Catal B: Environ 266:118617

Nguyen PY, Carvalho G, Reis MAM, Oehmen A (2021) Water Res 188:116446

Dong L, Xu T, Chen W, Lu W (2019) Chem Eng J 357:198–208

Acknowledgements

This work was supported by the "Pioneer" and "Leading Goose" R&D Program of Zhejiang (No. 2023C01207), National Natural Science Foundation of China (No. 12104405, No. 51703201) and Zhejiang Provincial Natural Science Foundation of China (No. LQ17E030003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fang, Y., Chen, F., Qin, X. et al. Cu–ZnO Composite Nanoparticles Loaded Catalytic Fiber Efficiently Inactivates Bacteria by Generating Active Species Without Needing Light. Catal Lett 154, 94–106 (2024). https://doi.org/10.1007/s10562-022-04070-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-022-04070-8