Abstract

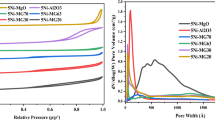

La/Mg ratio was evaluated in Ni–Mg–La–Al catalysts for the biogas dry reforming. The reactions were carried out in a fixed bed tubular reactor using synthetic biogas (70% CH4 and 30% CO2). The catalyst characterization showed that the increase of La/Mg ratio decreased the specific surface area of the catalyst and the average crystallite size of Ni0, but increased the acid strength of sites identified by NH3-TPD analysis. These properties contributed to improving the activity and catalytic stability for CH4 conversion at 700 °C. The Mg presence increased the strength of basic sites of the catalysts and plays an important role in CO2 conversion. The catalyst with La/Mg = 4 presented the best activity and stability for the reaction at 700 °C, due to the greater resistance to sintering associated with de small size of Ni0, and a proper combination of acid and basic sites. H2/CO ratios higher than 1 were obtained due to the contribution of the CH4 decomposition reaction.

Graphic Abstract

Similar content being viewed by others

References

Serrano-Lotina A, Rodríguez L, Muñoz G, Daza L (2011) Biogas reforming on La-promoted NiMgAl catalysts derived from hydrotalcite-like precursors. J Power Sources 196:4404–4410. https://doi.org/10.1016/j.jpowsour.2010.10.107

Xu J, Zhou W, Li Z et al (2009) Biogas reforming for hydrogen production over nickel and cobalt bimetallic catalysts. Int J Hydrog Energy 34:6646–6654. https://doi.org/10.1016/j.ijhydene.2009.06.038

Navas-Anguita Z, Cruz PL, Martín-Gamboa M et al (2019) Simulation and life cycle assessment of synthetic fuels produced via biogas dry reforming and Fischer–Tropsch synthesis. Fuel 235:1492–1500. https://doi.org/10.1016/j.fuel.2018.08.147

Hernández B, Martín M (2019) Optimal production of syngas via super-dry reforming. Analysis for natural gas and biogas under different CO2 taxes. Chem Eng Res Des 148:375–392. https://doi.org/10.1016/j.cherd.2019.06.030

Charisiou ND, Siakavelas G, Papageridis KN et al (2016) Syngas production via the biogas dry reforming reaction over nickel supported on modified with CeO2 and/or La2O3 alumina catalysts. J Nat Gas Sci Eng 31:164–183. https://doi.org/10.1016/j.jngse.2016.02.021

Gao Y, Jiang J, Meng Y et al (2018) A review of recent developments in hydrogen production via biogas dry reforming. Energy Convers Manage 171:133–155. https://doi.org/10.1016/j.enconman.2018.05.083

Zhou L, Li L, Wei N et al (2015) Effect of NiAl2O4 formation on Ni/Al2O3 stability during dry reforming of methane. ChemCatChem. https://doi.org/10.1002/cctc.201500379

Priebe GPS, Kipper E, Gusmão AL et al (2016) Anaerobic digestion of chrome-tanned leather waste for biogas production. J Clean Prod 129:410–416. https://doi.org/10.1016/j.jclepro.2016.04.038

Deublein D, Steinhauser A (2011) Biogas from waste and renewable resources. Wiley, Hoboken

Habibi N, Wang Y, Arandiyan H, Rezaei M (2017) Effect of substitution by Ni in MgAl2O4 spinel for biogas dry reforming. Int J Hydrog Energy 42:2–11. https://doi.org/10.1016/j.ijhydene.2017.07.222

Elsayed NH, Elwell A, Joseph B, Kuhn JN (2017) Effect of silicon poisoning on catalytic dry reforming of simulated biogas. Appl Catal A 538:157–164. https://doi.org/10.1016/j.apcata.2017.03.024

Cruz PL, Navas-Anguita Z, Iribarren D, Dufour J (2018) Exergy analysis of hydrogen production via biogas dry reforming. Int J Hydrog Energy 43:11688–11695. https://doi.org/10.1016/j.ijhydene.2018.02.025

Kathiraser Y, Wang Z, Ang ML et al (2017) Highly active and coke resistant Ni/SiO2 catalysts for oxidative reforming of model biogas: effect of low ceria loading. J CO2 Util 19:284–295. https://doi.org/10.1016/j.jcou.2017.03.018

Serrano-Lotina A, Daza L (2013) Highly stable and active catalyst for hydrogen production from biogas. J Power Sources 238:81–86. https://doi.org/10.1016/j.jpowsour.2013.03.067

Ren HP, Song YH, Wang W et al (2015) Insights into CeO2-modified Ni–Mg–Al oxides for pressurized carbon dioxide reforming of methane. Chem Eng J 259:581–593. https://doi.org/10.1016/j.cej.2014.08.029

Shimonosono T, Hirata Y, Changgan M et al (2018) Hydrogen production through dry reforming of biogas using a porous electrochemical cell: effects of a cobalt catalyst in the electrode and mixing of air with biogas. Ceram Int 44:8904–8912. https://doi.org/10.1016/j.ceramint.2018.02.082

Goula MA, Charisiou ND, Siakavelas G et al (2017) Syngas production via the biogas dry reforming reaction over Ni supported on zirconia modified with CeO2 or La2O3 catalysts. Int J Hydrog Energy 42:13724–13740. https://doi.org/10.1016/j.ijhydene.2016.11.196

Ugarte P, Durán P, Lasobras J et al (2017) Dry reforming of biogas in fluidized bed: Process intensification. Int J Hydrog Energy 42:13589–13597. https://doi.org/10.1016/j.ijhydene.2016.12.124

Benito M, Ortiz I, Rodriguez L, Munoz G (2015) NieCo bimetallic catalyst for hydrogen production in sewage treatment plants: biogas reforming and tars removal. Int J Hydrog Energy 40:14456–14468. https://doi.org/10.1016/j.ijhydene.2015.06.163

Durán P, Sanz-Martínez A, Soler J et al (2019) Pure hydrogen from biogas: intensified methane dry reforming in a two-zone fluidized bed reactor using permselective membranes. Chem Eng J 370:772–781. https://doi.org/10.1016/j.cej.2019.03.199

Calgaro CO, Perez-Lopez OW (2019) Biogas dry reforming for hydrogen production over Ni-M-Al catalysts (M = Mg, Li, Ca, La, Cu Co, Zn). Int J Hydrogen Energy 44:17750–17766. https://doi.org/10.1016/j.ijhydene.2019.05.113

Zhang J, Wang H, Dalai AK (2007) Development of stable bimetallic catalysts for carbon dioxide reforming of methane. J Catal 249:300–310. https://doi.org/10.1016/j.jcat.2007.05.004

Dahdah E, Rached JA, Aouad S et al (2017) CO2 reforming of methane over NixMg6xAl2 catalysts: effect of lanthanum doping on catalytic activity and stability. Int J Hydrog Energy 42:12808–12817. https://doi.org/10.1016/j.ijhydene.2017.01.197

Charisiou ND, Iordanidis A, Polychronopoulou K et al (2018) Studying the stability of Ni supported on modified with CeO2 alumina catalysts for the biogas dry reforming reaction. Mater Today Proc 5:27607–27616. https://doi.org/10.1016/j.matpr.2018.09.081

Rosha P, Mohapatra SK, Mahla SK, Dhir A (2019) Catalytic reforming of synthetic biogas for hydrogen enrichment over Ni supported on ZnO[sbnd]CeO2 mixed catalyst. Biomass Bioenergy 125:70–78. https://doi.org/10.1016/j.biombioe.2019.04.013

Ha QLM, Armbruster U, Kreyenschulte C et al (2019) Stabilization of low nickel content catalysts with lanthanum and by citric acid assisted preparation to suppress deactivation in dry reforming of methane. Catal Today 334:203–214. https://doi.org/10.1016/j.cattod.2018.11.021

Das S, Ashok J, Bian Z et al (2018) Silica-Ceria sandwiched Ni core–shell catalyst for low temperature dry reforming of biogas: coke resistance and mechanistic insights. Appl Catal B 230:220–236. https://doi.org/10.1016/j.apcatb.2018.02.041

Perez-Lopez OW, Senger A, Marcilio NR, Lansarin MA (2006) Effect of composition and thermal pretreatment on properties of Ni–Mg–Al catalysts for CO2 reforming of methane. Appl Catal A 303:234–244. https://doi.org/10.1016/j.apcata.2006.02.024

Wei Q, Yang G, Gao X et al (2018) Facile one-step synthesis of mesoporous Ni–Mg–Al catalyst for syngas production using coupled methane reforming process. Fuel 211:1–10. https://doi.org/10.1016/j.fuel.2017.08.093

Zhang T, Liu Z, Zhu YA et al (2020) Dry reforming of methane on Ni–Fe–MgO catalysts: influence of Fe on carbon-resistant property and kinetics. Appl Catal B. https://doi.org/10.1016/j.apcatb.2019.118497

Ashok J, Bian Z, Wang Z, Kawi S (2018) Ni-phyllosilicate structure derived Ni–SiO2–MgO catalysts for bi-reforming applications: acidity, basicity and thermal stability. Catal Sci Technol 8:1730–1742. https://doi.org/10.1039/c7cy02475d

Schiaroli N, Lucarelli C, Sanghez de Luna G et al (2019) Ni-based catalysts to produce synthesis gas by combined reforming of clean biogas. Appl Catal A 582:117087. https://doi.org/10.1016/j.apcata.2019.05.021

Rosset M, Féris LA, Perez-Lopez OW (2020) Biogas dry reforming over Ni–Al catalyst: suppression of carbon deposition by catalyst preparation and activation. Int J Hydrog Energy 45:6549–6562. https://doi.org/10.1016/j.ijhydene.2019.12.207

Sikander U, Sufian S, Salam MA (2017) A review of hydrotalcite based catalysts for hydrogen production systems. Int J Hydrog Energy 42:19851–19868. https://doi.org/10.1016/j.ijhydene.2017.06.089

Rosset M, Sfreddo LW, Hidalgo GEN et al (2019) Adsorbents derived from hydrotalcites for the removal of diclofenac in wastewater. Appl Clay Sci 175:150–158. https://doi.org/10.1016/j.clay.2019.04.014

Białas A, Mazur M, Natka P et al (2016) Hydrotalcite-derived cobalt–aluminum mixed oxide catalysts for toluene combustion. Appl Surf Sci 362:297–303. https://doi.org/10.1016/j.apsusc.2015.11.211

Cavani F, Trifirb F (1991) Hydrotalcite-type anionic clays: preparation, properties and applications. Catal Today 11:173–301

Tathod AP, Hayek N, Shpasser D et al (2019) Mediating interaction strength between nickel and zirconia using a mixed oxide nanosheets interlayer for methane dry reforming. Appl Catal B 249:106–115. https://doi.org/10.1016/j.apcatb.2019.02.040

Izquierdo-Colorado A, Dębek R, Da Costa P, Gálvez ME (2018) Excess-methane dry and oxidative reforming on Ni-containing hydrotalcite-derived catalysts for biogas upgrading into synthesis gas. Int J Hydrog Energy 43:11981–11989. https://doi.org/10.1016/j.ijhydene.2018.04.237

Liu H, Wierzbicki D, Debek R et al (2016) La-promoted Ni-hydrotalcite-derived catalysts for dry reforming of methane at low temperatures. Fuel 182:8–16. https://doi.org/10.1016/j.fuel.2016.05.073

Kalai DY, Stangeland K, Jin Y et al (2018) Biogas dry reforming for syngas production on La promoted hydrotalcite-derived Ni catalysts. Int J Hydrog Energy 43:19438–19450. https://doi.org/10.1016/j.ijhydene.2018.08.181

Kalai DY, Stangeland K, Li H, Yu Z (2017) The effect of la on the hydrotalcite derived Ni catalysts for dry reforming of methane. Energy Procedia 142:3721–3726. https://doi.org/10.1016/j.egypro.2017.12.267

Serrano-lotina A, Martin AJ, Folgado MA, Daza L (2012) Dry reforming of methane to syngas over La-promoted hydrotalcite clay-derived catalysts. Int J Hydrogen Energy 37:12342–12350

Serrano-lotina A, Rodríguez L, Muñoz G et al (2011) Biogas reforming over La–NiMgAl catalysts derived from hydrotalcite-like structure: influence of calcination temperature. Catal Commun 12:961–967. https://doi.org/10.1016/j.catcom.2011.02.014

Ni J, Chen L, Lin J et al (2013) High performance of Mg–La mixed oxides supported Ni catalysts for dry reforming of methane: the effect of crystal structure. Int J Hydrog Energy 38:13631–13642. https://doi.org/10.1016/j.ijhydene.2013.08.041

Hermes NA, Lansarin MA, Perez-Lopez OW (2011) Catalytic decomposition of methane over M–Co–Al catalysts (M5Mg, Ni, Zn, Cu). Catal Lett 141:1018–1025. https://doi.org/10.1007/s10562-011-0611-5

Escobar C, Perez-Lopez OW (2014) Hydrogen production by methane decomposition over Cu–Co–Al mixed oxides activated under reaction conditions. Catal Lett. https://doi.org/10.1007/s10562-014-1234-4

Calgaro CO, Perez-Lopez OW (2017) Decomposition of methane over Co3–xAlxO4 (x = 0–2) coprecipitated catalysts: the role of Co phases in the activity and stability. Int J Hydrog Energy 42:29756–29772. https://doi.org/10.1016/j.ijhydene.2017.10.082

Zardin L, Perez-Lopez OW (2017) Hydrogen production by methane decomposition over Co–Al mixed oxides derived from hydrotalcites: effect of the catalyst activation with. Int J Hydrogen Energy 42:7895–7907. https://doi.org/10.1016/j.ijhydene.2017.02.153

Lu Y, Zhou P, Han J, Yu F (2015) Fischer–Tropsch synthesis of liquid hydrocarbons over mesoporous SBA-15 supported cobalt catalysts. RSC Adv 5:59792–59803. https://doi.org/10.1039/C5RA10123A

Calgaro CO, Perez-Lopez OW (2019) Graphene and carbon nanotubes by CH4 decomposition over Co–Al catalysts. Mater Chem Phys 226:6–19. https://doi.org/10.1016/j.matchemphys.2018.12.094

Gousi M, Andriopoulou C, Bourikas K et al (2017) Green diesel production over nickel-alumina co-precipitated catalysts. Appl Catal A Gen 536:45–56. https://doi.org/10.1016/j.apcata.2017.02.010

de Lima SM, da Silva AM, da Costa LO, Assaf JM, Jacobs G, Davis BH, Mattos LV, Noronha FB (2010) Evaluation of the performance of Ni/La2O3 catalyst prepared from LaNiO3 perovskite-type oxides for the production of hydrogen through steam reforming and oxidative steam reforming of ethanol. Appl Catal A 377:181–190. https://doi.org/10.1016/j.apcata.2010.01.036

Smith WF, Hashemi J (2012) Fundamentos de Engenharia e Ciência dos Materiais, 5 ed

Kathiraser Y, Thitsartarn W, Sutthiumporn K, Kawi S (2013) Inverse NiAl2O4 on LaAlO3–Al2O3: unique catalytic structure for stable CO2 reforming of methane. J Phys Chem C 117:8120–8130. https://doi.org/10.1021/jp401855x

Song JH, Yoo S, Yoo J et al (2017) Hydrogen production by steam reforming of ethanol over Ni/Al2O3–La2O3 xerogel catalysts. Mol Catal 434:123–133. https://doi.org/10.1016/j.mcat.2017.03.009

Liu H, Hadjltaief HB, Benzina M et al (2019) Natural clay based nickel catalysts for dry reforming of methane: on the effect ScienceDirect natural clay based nickel catalysts for dry reforming of methane: on the effect of support promotion (La, Al, Mn). Int J Hydrogen Energy 44:246–255. https://doi.org/10.1016/j.ijhydene.2018.03.004

Nikoo MK, Amin NAS (2011) Thermodynamic analysis of carbon dioxide reforming of methane in view of solid carbon formation. Fuel Process Technol 92:678–691. https://doi.org/10.1016/j.fuproc.2010.11.027

Oemar U, Kathiraser Y, Mo L et al (2016) CO2 reforming of methane over highly active La-promoted Ni supported on SBA-15 catalysts: mechanism and kinetic modelling. Catal Sci Technol 6:1173–1186. https://doi.org/10.1039/c5cy00906e

Luhrs CC, Moberg M, Maxson A et al (2014) IF-WS2/nanostructured carbon hybrids generation and their characterization. Inorganics 2:211–232. https://doi.org/10.3390/inorganics2020211

Soldano C, Mahmood A, Dujardin E (2010) Production, properties and potential of graphene. Carbon N Y 48:2127–2150. https://doi.org/10.1016/j.carbon.2010.01.058

Tu Z, Liu Z, Li Y et al (2014) Controllable growth of 1–7 layers of graphene by chemical vapour deposition. Carbon N Y 73:252–258. https://doi.org/10.1016/j.carbon.2014.02.061

Guo J, Lou H, Zheng X (2007) The deposition of coke from methane on a Ni/MgAl2O4 catalyst. Carbon N Y 45:1314–1321. https://doi.org/10.1016/j.carbon.2007.01.011

Turap Y, Wang I, Fu T et al (2020) Co–Ni alloy supported on CeO2 as a bimetallic catalyst for dry reforming of methane. Int J Hydrogen Energy 45:6538–6548. https://doi.org/10.1016/j.ijhydene.2019.12.223

Jabbour K, Saad A, Inaty L et al (2019) Ordered mesoporous Fe-Al2O3 based-catalysts synthesized via a direct “one-pot” method for the dry reforming of a model biogas mixture. Int J Hydrogen Energy 44:14889–14907. https://doi.org/10.1016/j.ijhydene.2019.04.110

Calgaro CO, Rocha AL, Perez-Lopez OW (2020) Deactivation control in CO2 reforming of methane over Ni–Mg–Al catalyst. React Kinet Mech Catal. https://doi.org/10.1007/s11144-020-01770-3

Charisiou ND, Tzounis L, Sebastian V et al (2019) Investigating the correlation between deactivation and the carbon deposited on the surface of Ni/Al2O3 and Ni/La2O3–Al2O3 catalysts during the biogas reforming reaction. Appl Surf Sci 474:42–56. https://doi.org/10.1016/j.apsusc.2018.05.177

Acknowledgements

The authors are grateful for the financial support provided by CAPES (Brazilian Agency for Improvement of Graduate Personnel) and CNPq (National Council of Science and Technological Development).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Calgaro, C.O., Lima, D.S., Tonietto, R. et al. Biogas Dry Reforming Over Ni–Mg–La–Al Catalysts: Influence of La/Mg Ratio. Catal Lett 151, 267–280 (2021). https://doi.org/10.1007/s10562-020-03296-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-020-03296-8