Abstract

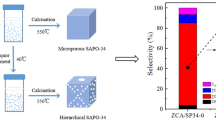

Synthesis of light hydrocarbons from synthesis gas using bifunctional catalysts consisting of CuO–ZnO–Al2O3 methanol synthesis catalysts and SAPO-5 were investigated in a fixed bed reactor. The operating results showed that both the temperature and the ratio of CZA/SAPO-5 influenced the CO conversion and the selectivity of the catalysts. The effects of different dehydration component such as HZSM-5, HMOR and SAPO-5 and subsequently the impact of the zeolite acidity on the catalytic performance were also investigated. Experimental results indicated that zeolites in bifunctional catalysts played the crucial role for the distribution of hydrocarbons, and SAPO-5 was superior to the other zeolites in terms of better conversion and C3–C5 selectivity due to its suitable topology and proper acidic property. The efficiency of the CZA/SAPO-5 catalysts was found to be directly proportional to the Brönsted acid sites density of the zeolite and Brönsted acid sites are the likely zeolite active sites for DME dehydration. High time–space yield (461.6 mg mL−1 h−1) and high selectivity (88.1%) of light hydrocarbons (C3–C5) could be achieved on the CZA/SAPO-5-0.4 catalyst at 290 °C.

Graphic Abstract

Similar content being viewed by others

References

Yang S, Xiao L, Yang S, Kraslawski A, Man Y, Qian Y (2014) ACS Sustain Chem Eng 2:80. https://doi.org/10.1021/sc400336e

Zhang S, Li D, Liu Y, Zhang Y, Wu Q (2019) Catal Lett 149:1486. https://doi.org/10.1007/s10562-019-02775-x

Cheng K, Zhang L, Kang J, Peng X, Zhang Q, Wang Y (2015) Chem Eur J 21:1928. https://doi.org/10.1002/chem.201405277

Yang J, Gong K, Miao D, Jiao F, Pan X, Meng X, Xiao F, Bao X (2019) J Energy Chem 35:44. https://doi.org/10.1016/j.jechem.2018.10.008

Kondratenko EV, Peppel T, Seeburg D, Kondratenko VA, Kalevaru N, Martin A, Wohlrab S (2017) Catal Sci Technol 7:366. https://doi.org/10.1039/C6CY01879C

Batamack PTD, Mathew T, Prakash GKS (2017) J Am Chem Soc 139:18078. https://doi.org/10.1021/jacs.7b10725

Alayat A, Mcllroy DN, McDonald AG (2018) Fuel Process Technol 169:132. https://doi.org/10.1016/j.fuproc.2017.09.011

Nie C, Zhan H, Ma H, Qian W, Sun Q, Ying W (2019) Catal Lett 149:1375. https://doi.org/10.1007/s10562-019-02700-2

Xue Y, Ge H, Chen Z, Zhai Y, Zhang J, Sun J, Abbas M, Lin K, Zhao W, Chen J (2018) J Catal 358:237. https://doi.org/10.1016/j.jcat.2017.12.017

Xu K, Sun B, Lin J, Wen W, Pei Y, Yan S, Qiao M, Zhang X, Zong B (2014) Nat Commun 5:5783. https://doi.org/10.1038/ncomms6783

Hibbitts D, Dybeck E, Lawlor T, Neurock M, Iglesia E (2016) J Catal 337:91. https://doi.org/10.1016/j.jcat.2016.01.010

Dry ME (2002) Catal Today 71:227. https://doi.org/10.1016/S0920-5861(01)00453-9

Wang C, Yang J, Sun Y, Li Q, Zheng Y, Hu YH (2019) Fuel 244:395. https://doi.org/10.1016/j.fuel.2019.02.024

Zhao B, Zhai P, Wang P, Li J, Li T, Peng M, Zhao M, Hu G, Yang Y, Li YW, Zhang Q, Fan W, Ma D (2017) Chem 3:323. https://doi.org/10.1016/j.chempr.2017.06.017

Harmel J, Peres L, Estrader M, Berliet A, Maury S, Fécant A, Chaudret B, Serp P, Soulantica K (2018) Angew Chem Int Ed 57:10579. https://doi.org/10.1002/anie.201804932

Li J, Pan X, Bao X (2015) Chin J Catal 36:1131. https://doi.org/10.1016/S1872-2067(14)60297-7

Chinchen GC, Denny PJ, Parker DG, Spencer MS, Whan DA (1987) Appl Catal 30:333. https://doi.org/10.1016/S0166-9834(00)84123-8

Deng X, Liu Y, Huang W (2018) J Energy Chem 27:319. https://doi.org/10.1016/j.jechem.2017.10.007

Kim J-H, Park MJ, Kim SJ, Joo O-S, Jung K-D (2004) Appl Catal A 264:37. https://doi.org/10.1016/j.apcata.2003.12.058

Kuld S, Thorhauge M, Falsig H, Elkjær CF, Helveg S, Chorkendorff I, Sehested J (2016) Science 352:969. https://doi.org/10.1126/science.aaf0718

Behrens M, Studt F, Kasatkin I, Kühl S, Hävecker M, Abild-Pedersen F, Zander S, Girgsdies F, Kurr P, Kniep B-L, Tovar M, Fischer RW, Nørskov JK, Schlögl R (2012) Science 336:893. https://doi.org/10.1126/science.1219831

Chen Y, Xu Y, Cheng D-G, Chen Y, Chen F, Lu X, Huang Y, Ni S (2015) J Chem Technol Biotechnol 90:415. https://doi.org/10.1002/jctb.4309

Nieskens DLS, Ciftci A, Groenendijk PE, Wielemaker MF, Malek A (2017) Ind Eng Chem Res 56:2722. https://doi.org/10.1021/acs.iecr.6b04643

Zhang Q, Li X, Asami K, Asaoka S, Fujimoto K (2005) Catal Lett 102:51. https://doi.org/10.1007/s10562-005-5202-x

Ge Q, Lian Y, Yuan X, Li X, Fujimoto K (2008) Catal Commun 9:256. https://doi.org/10.1016/j.catcom.2007.06.011

Lu P, Shen D, Cheng S, Hondo E, Chizema LG, Wang C, Gai X, Lu C, Yang R (2018) Fuel 223:157. https://doi.org/10.1016/j.fuel.2018.02.159

Ma X, Ge Q, Ma J, Xu H (2013) Fuel Process Technol 109:1. https://doi.org/10.1016/j.fuproc.2013.01.002

Zhang Q, Li X, Asami K, Asaoka S, Fujimoto K (2004) Fuel Process Technol 85:1139. https://doi.org/10.1016/j.fuproc.2003.10.016

Li C, Yuan X, Fujimoto K (2014) Appl Catal A 475:155. https://doi.org/10.1016/j.apcata.2014.01.025

Ereña J, Arandes JM, Bilbao J, Olazar M, de Lasa HI (1999) J Chem Technol Biotechnol 72:190. https://doi.org/10.1002/(SICI)1097-4660(199806)72:2%3c190:AID-JCTB895%3e3.0.CO;2-8

Mysov VM, Reshetnikov SI, Stepanov VG, Ione KG (2005) Chem Eng J 107:63. https://doi.org/10.1016/j.cej.2004.12.011

Dagle RA, Lizarazo-Adarme JA, Lebarbier Dagle V, Gray MJ, White JF, King DL, Palo DR (2014) Fuel Process Technol 123:65. https://doi.org/10.1016/j.fuproc.2014.01.041

Lorenz E, Wehling P, Schlereth M, Kraushaar-Czarnetzki B (2016) Catal Today 275:183. https://doi.org/10.1016/j.cattod.2016.03.004

Flores JH, da Silva MIP (2016) Catal Lett 146:1505. https://doi.org/10.1007/s10562-016-1771-0

Haw JF, Song W, Marcus DM, Nicholas JB (2003) Acc Chem Res 36:317. https://doi.org/10.1021/ar020006o

Wang C, Ma X, Ge Q, Xu H (2015) Catal Sci Technol 5:1847. https://doi.org/10.1039/C4CY01494D

Cheng K, Zhou W, Kang J, He S, Shi S, Zhang Q, Pan Y, Wen W, Wang Y (2017) Chem 3:334. https://doi.org/10.1016/j.chempr.2017.05.007

Gayubo AG, Benito PL, Aguayo AT, Olazar M, Bilbao J (1996) J Chem Technol Biotechnol 65:186. https://doi.org/10.1002/(SICI)1097-4660(199602)65:2%3c186:AID-JCTB401%3e3.0.CO;2-J

Wang L, Guo C, Yan S, Huang X, Li Q (2003) Micropor Mesopor Mater 64:63. https://doi.org/10.1016/S1387-1811(03)00482-7

Guisnet M, Ayrault P, Datka J (1997) Pol J Chem 71:1455

van Bennekom JG, Venderbosch RH, Winkelman JGM, Wilbers E, Assink D, Lemmens KPJ, Heeres HJ (2013) Chem Eng Sci 87:204. https://doi.org/10.1016/j.ces.2012.10.013

García-Trenco A, Martínez A (2012) Appl Catal A 411–412:170. https://doi.org/10.1016/j.apcata.2011.10.036

Yuen L-T, Zones SI, Harris TV, Gallegos EJ (1994) Micropor Mater 2:105. https://doi.org/10.1016/0927-6513(93)E0039-J

Westgård Erichsen M, Svelle S, Olsbye U (2013) J Catal 298:94. https://doi.org/10.1016/j.jcat.2012.11.004

Westgård Erichsen M, Svelle S, Olsbye U (2013) Catal Today 215:216. https://doi.org/10.1016/j.cattod.2013.03.017

Lebarbier VM, Dagle RA, Kovarik L, Lizarazo-Adarme JA, King DL, Palo DR (2012) Catal Sci Technol 2:2116. https://doi.org/10.1039/C2CY20315D

Acknowledgements

This work was supported by the China Postdoctoral Science Foundation (2018M642769) for the financial supports.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, T., Lu, T., Yang, M. et al. Enhanced Catalytic Performance of CuO–ZnO–Al2O3/SAPO-5 Bifunctional Catalysts for Direct Conversion of Syngas to Light Hydrocarbons and Insights into the Role of Zeolite Acidity. Catal Lett 149, 3338–3348 (2019). https://doi.org/10.1007/s10562-019-02901-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-02901-9