Abstract

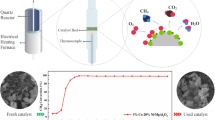

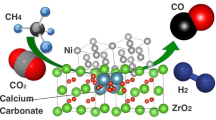

A series of highly dispersed nickel (Ni)-based catalysts supported on cerium (Ce)-modified high surface area magnesium–aluminum (MgAl) spinel support were prepared via a coprecipitation and impregnation method for high temperature syngas methanation. The influence of Ce substitution on the catalyst’s textural property were investigated via characterization by BET, XRD, TEM, H2-TPR, XPS, H2-TPD, and CO-TPD. The appropriate Ce species addition significantly increased catalyst surface area, improved active metal dispersion, and retained moderate interactions between NiO and support, which in turn enhanced Ni availability and suppressed aggregation. Meanwhile, the surface Ni0 concentration and oxygen vacancy number was improved, leading to easier dissociation for carbon monoxide (CO), which significantly contributed to high temperature methanation. Among all catalysts, Ni/MgAl-5Ce achieved the best catalytic performance at 500 °C, 2.0 MPa, and 30,000 ml g−1 min−1, with CO conversion, CO2 conversion, and CH4 selectivity at 99.2, 42.7, and 98.9%, respectively. Furthermore, Ni/MgAl-5Ce maintained excellent stability during a 50 h life test.

Graphic Abstract

Similar content being viewed by others

References

Razzaq R, Li CS, Zhang SJ (2013) coke oven gas: availability, properties, purification, and utilization in China. Fuel 113:287–299

Zhu HW, Razzaq R, Jiang L, Li CS (2012) Low-temperature methanation of CO in coke oven gas using single nanosized Co3O4 catalysts. Catal Commun 23:43–47

Xavier KO, Sreekala R, Rashid KKA, Yusuff KKM, Sen B (1999) Doping effects of ceriumoxide on Ni/Al2O3 catalysts for methanation. Catal Today 49:17–21

Zhao AM, Ying WY, Zhang HT, Ma HF, Fang DY (2012) Ni–Al2O3 catalysts prepared by solution combustion method for syngas methanation. Catal Commun 17:34–38

Fujita S, Terunuma H, Nakamura M, Takezawa N (1991) Mechanisms of methanation of CO and CO2 over Ni. Ind Eng Chem Res 30:1146–1151

Tada S, Minori D, Otsuka F, Kikuchi R, Osada K, Akiyama K, Satokawa S (2014) Effect of Ru and Ni ratio on selective CO methanation over Ru–Ni/TiO2. Fuel 129:219–224

Boffa A, Lin C, Bell AT, Somorjai GA (1994) Promotion of CO and CO2 hydrogenation over Rh by metal oxides: the influence of oxide lewis acidity and reducibility. J Catal 149:149–158

Park JN, Mcfarland EW (2009) A highly dispersed Pd-Mg/SiO2 catalyst active for methanation of CO2. J Catal 266:92–97

Ashok J, Kawi S (2014) Nickel–iron alloy supported over iron-alumina catalysts for steam reforming of biomass tar model compound. ACS Catal 4:289–301

Rostrup-Nielsen JR, Pedersen K, Sehested J (2007) High temperature methanation: sintering and structure sensitivity. Appl Catal A Gen 330:134–138

Li DL, Lu MM, Cai YB, Cao YN, Zhan YY, Jiang LL (2016) Synthesis of high surface area MgAl2O4 spinel as catalyst support via layered double hydroxides-containing precursor. Appl Clay Sci 132:243–250

Guo J, Lou H, Zhao H, Chai D, Zheng X (2004) Dry reforming of methane over nickel catalysts supported on magnesium aluminate spinels. Appl Catal A Gen 273:75–82

Szijjártó GP, Pászti Z, Sajó I, Erdőhelyi A, Radnóczi G, Tompos A (2013) Nature of the active sites in Ni/MgAl2O4-based catalysts designed for steam reforming of ethanol. J Catal 305:290–306

Evans OR, Bell AT, Tilley TD (2004) Oxidative dehydrogenation of propane over vanadia-based catalysts supported on high-surface-area mesoporous MgAl2O4. J Catal 226:292–300

Bocanegra SA, Ballarini AD, Scelza OA, deMiguel SR (2008) The influence of the synthesis routes of MgAl2O4 on its properties and behavior as support of dehydrogenation catalysts. Mater Chem Phys 111:534–541

Villa A, Gaiassi A, Rossetti I, Bianchi CL, van Benthem K, Veith GM, Prati L (2010) Au on MgAl2O4 spinels: the effect of support surface properties in glycerol oxidation. J Catal 275:108–116

Alvar EN, Rezaei M, Alvar HN (2010) Synthesis of mesoporous nanocrystalline MgAl2O4 spinel via surfactant assisted precipitation route. Powder Tech 198:275–278

Mosayebi Z, Rezaei M, Hadian N, Kordshuli FZ, Meshkani F (2012) Low temperature synthesis of nanocrystalline magnesium aluminate with high surface area by surfactant assisted precipitation method: effect of preparation conditions. Mater Res Bull 47:2154–2160

Rashad MM, Zaki ZI, El-Shall H (2009) A novel approach for synthesis of nanocrystalline MgAl2O4 powders by co-precipitation method. J Mater Sci 44:2992–2998

Zhou JY, Ma HF, Zhang HT, Ying WY (2017) The preparation of high surface area Ni/MgAl2O4 catalysts for syngas methanation. World Acad Sci Eng Technol Int J Chem Mol Eng 11:200

Fornasiero P, Dimonte R, Rao GR, Kaspar J, Meriani S, Trovarelli A (1995) Rh loaded CeO2–ZrO2 solid-solutions as highly efficient oxygen exchangers: dependence of the reduction behavior and the oxygen storage capacity on the structural-properties. J Catal 151:168–177

Zen Y, Ma HF, Zhang HT, Ying WY, Fang DY (2015) Ni–Ce–Al composite oxides catalysts synthesized by solution combustion method: enhanced catalytic activity for CO methanation. Fuel 162:16–22

Chen W, Zhao GF, Xue QS, Chen L, Lu Y (2013) High carbon-resistance Ni/CeAlO3–Al2O3 catalyst for CH4/CO2 reforming. Appl Catal B Environ 136:260–268

Leofanti G, Padovan M, Tozzola G, Venturelli B (1998) Surface area and pore texture of catalysts. Catal Today 41:207–219

Gong DD, Li SS, Guo SX, Tang HG, Wang H, Liu Y (2018) Lanthanum and cerium co-modified Ni/SiO2 catalyst for CO methanation from syngas. Appl Surf Sci 434:351–364

Liu Q, Gao JJ, Zhang MJ, Li HF, Gu FN, Xu GW, Zhong ZY, Su FB (2014) Highly active and stable Ni/g-Al2O3 catalysts selectively deposited with CeO2 for CO methanation. RSC Adv 4:16094–16103

Bae JW, Kim R, Baek SC, Jun KW (2011) The role of CeO2-ZrO2 distribution on the Ni/MgAl2O4 catalyst during the combined steam and CO2 reforming of methane. Reac Kinet Mech Cat 104:377–388

Lima SM, Assaf JM, Peña MA, Fierro JLG (2006) Structural features of La1-xCexNiO3 mixed oxides and performance for the dry reforming of methane. Appl Catal A Gen 311:94–104

Wang XL, Zhu LJ, Liu YC, Wang SR (2018) CO2 methanation on the catalyst of Ni/MCM-41 promoted with CeO2. Sci Total Environ 625:686–695

Yan X, Liu Y, Zhao B, Wang Z, Wang Y, Liu C (2013) Methanation over Ni/SiO2: effect of the catalyst preparation methodologies. Int J Hydrogen Energy 38:2283–2291

Zou XJ, Wang XG, Li L, Shen K, Lu XG, Ding WZ (2010) Development of highly effective supported nickel catalysts for pre-reforming of liquefied petroleum gas under low steam to carbon molar ratios. Int J Hydrogen Energy 35:12191–12200

Koo KY, Roh HS, Seo YT, Seo DJ, Yoon WL, Park SB (2008) A highly effective and stable nano-sized Ni/MgO–Al2O3 catalyst for gas to liquids (GTL) process. Int J Hydrogen Energy 33:2036–2043

Zhou JY, Ma HF, Jin FY, Zhang HT, Ying WY (2018) Mn and Mg dual promoters modified Ni/α-Al2O3 catalysts for high temperature syngas methanation. Fuel Process Technol 172:225–232

Saw ET, Oemar U, Tan XR, Du Y, Borgn A, Hidajata K, Kawi S (2014) Bimetallic Ni-Cu catalyst supported on CeO2 for high-temperature water-gas shift reaction: methane suppression via enhanced CO adsorption. J Catal 314:32–46

Li ZW, Li M, Ashok J, Kawi S (2019) NiCo@NiCo phyllosilicate@CeO2 hollow core shell catalysts for steam reforming of toluene as biomass tar model compound. Energy Conver Manage 180:822–830

Nelson AE, Schulz KH (2003) Surface chemistry and microstructural analysis of CexZr1−xO2−y model catalyst surfaces. Appl Surf Sci 210:206–221

Zhang F, Wang P, Koberstein J, Khalid S, Chan SW (2004) Cerium oxidation state in ceria nanoparticles studied with X-ray photoelectron spectroscopy and absorption near edge spectroscopy. Surf Sci 563:74–82

Li ZW, Kawi S (2018) Facile synthesis of multi-Ni-Core@Ni Phyllosilicate@CeO2 shell hollow spheres with high oxygen vacancy concentration for dry reforming of CH4. Chem Cat Chem 10:1–9

Velu S, Gangwal SK (2006) Synthesis of alumina supported nickel nanoparticle catalysts and evaluation of nickel metal dispersions by temperature programmed desorption. Solid State Ionics 177:803–811

Tao M, Xin Z, Meng X, Lv Y, Bian Z (2016) Impact of double-solvent impregnation on the Ni dispersion of Ni/SBA-15 catalysts and catalytic performance for the syngas methanation. RSC Adv 6:35875–35883

Zeng Y, Ma HF, Zhang HT, Ying WY, Fang DY (2014) Highly efficient NiAl2O4-free Ni/γ-Al2O3 catalysts prepared by solution combustion method for CO methanation. Fuel 137:155–163

Li ZW, Wang ZG, Jiang B, Kawi S (2018) Sintering resistant Ni nanoparticles exclusively confined within SiO2 nanotubes for CH4 dry reforming. Catal Sci Technol 8:3363–3371

Acknowledgements

This work is financially supported by the National Science and Technology Supporting Plan (No. 2012AA050102) and the Fundamental Research Funds for the Central Universities (No. 222201917013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, J., Ma, H., Liu, C. et al. Ni Based Catalysts Supported on Ce Modified MgAl Spinel Supports for High Temperature Syngas Methanation. Catal Lett 149, 2563–2574 (2019). https://doi.org/10.1007/s10562-019-02868-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-02868-7