Abstract

In this work, titanium-doped mesoporous Al2O3 (γ-Ti–Al2O3) was prepared by an evaporation-induced self-assembly method and used as a carrier of Ba/γ-Ti–Al2O3 catalyst to catalyze the aldol condensation of methyl acetate with formaldehyde to methyl acrylate in a fixed-bed reactor. The catalysts were characterized by X-ray diffraction, X-ray photoelectron spectroscopy, N2 adsorption–desorption, pyridine absorption performed via Fourier transform infrared spectroscope (Py-IR), and NH3 and CO2 temperature-programmed desorption (NH3 and CO2-TPD). Experimental results indicated that the doping of the titanium species into the frame work of mesoporous Al2O3 (γ-Ti–Al2O3) had a significant influence on the catalytic activity via modifying the acid–base surface properties of the catalyst. Furthermore, the Ba/γ-Ti–Al2O3 catalyst demonstrated excellent catalytic performance, with a methyl acetate conversion rate of 50% and methyl acrylate selectivity up to 90.2%. Compared with the Ba/Al2O3 catalyst, the Ba/γ-Ti–Al2O3 catalyst had better catalytic activity, stability and potential for practical application, which was likely due to an increased number of Lewis acid sites, especially the medium acid sites.

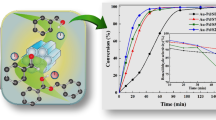

Graphical Abstract

Barium supported mesoporous γ-Ti–Al2O3 catalyst was found to be an effective catalyst for vapor phase aldol condensation of methyl acetate with formaldehyde.

Similar content being viewed by others

References

Danner H, Dürms M, Gartner M, Braun R (1998) Appl Biochem Biotechnol 70:887

Xu X, Lin J, Cen P (2006) Chin J Chem Eng 14:419–427

Nagai K (2001) Appl Catal A 221:367–377

Vlcˇek P, Lochmann L (1999) Prog Polym Sci 24:793–873

Lin MM (2001) Appl Catal A 207:1–16

Balcells E, Borgmeier F, Grißtede I, Lintz HG, Rosowski F (2004) Appl Catal A 266:211–221

Ishikawa S, Yi X, Murayama T, Ueda W (2014) Catal Today 238:35–40

Hävecker M, Wrabetz S, Kröhnert J, Csepei L, d’Alnoncourt R, Kolen’ko Y, Girgsdies F, Schlögl R, Trunschke A (2012) J Catal 285:48–60

d’Alnoncourt R, Csepei L, Hävecker M, Girgsdies F, Schustera M, Schlögl R, Trunschke A (2014) J Catal 311:369–385

Zhai Z, Getsoian A, Bell A (2013) J Catal 308:25–36

Cheung P, Bhan A, Sunley GJ, Law DJ, Iglesia E (2007) J Catal 245:110–123

Liu J, Xue H, Huang X, Wu P, Huang S, Liu S, Shen W (2010) Chin J Catal 31:729–738

Trost BM, Brindle CS (2010) Chem Soc Rev 39:1600–1632

Palomo C, Oiarbide M, García JM (2004) Chem Soc Rev 33:65–75

Bui TV, Sooknoi T, Resasco DE (2017) ChemSusChem 10:1631 – 1639

Fäseke VC, Sparr C (2016) Angew Chem Int Ed 55:7261 – 7264

Ai M (1987) J Catal 107:201–208

Ai M (1988) J Catal 112:194–200

Ai M (1989) Appl Catal 48:51–61

Ai M (1989) Appl Catal 54:29–36

Ai M (1990) Appl Catal 59:227–235

Feng X, Sun B, Yao Y, Su Q, Ji W, Au CT (2014) J Catal 314:132

Yang D, Li D, Yao H, Zhang G, Jiao T, Li Z, Li C, Zhang S (2015) Ind Eng Chem Res 54:6865–6873

Yan J, Zhang C, Ning C, Tang Y, Zhang Y, Chen L, Gao S, Wang Z, Zhang W (2015) J Ind Eng Chem 25:344

Wang Y, Lang X, Zhao G, Chen H, Fan Y, Yu L, Ma X, Zhu Z (2015) RSC Adv 5:32826

Roy S, Mpourmpakis G, Hong DY, Vlachos DG, Bhan A, Gorte RJ (2012) ACS Catal 2:1846–1853

Trueba M, Trasatti SP (2005) Eur J Inorg Chem 2005:3393–3403

Bao Q, Bu T, Yan J, Zhang C, Ning C, Zhang Y, Hao M, Zhang W, Wang Z (2017) Catal Lett 147:1540–1550

Bao Q, Zhu W, Yan J, Zhang C, Ning C, Zhang Y, Hao M, Wang Z (2017) RSC Adv 7:52304

Jiang F, Zeng L, Li S, Liu G, Wang S, Gong J (2015) ACS Catal 5:438–447

Xu B, Xiao T, Yan Z, Sun X, Sloan J, González-Cortés SL, Alshahrani F, Green MLH (2006) Microporous Mesoporous Mater 91:293–295

Bing J, Hu C, Zhang L (2017) Appl Catal B 202:118–126

Bang Y, Park S, Han SJ, Yoo J, Song JH, Choi JH, Kang KH, Song IK (2016) Appl Catal B 180:179–188

Parlett CMA, Durndell LJ, Machado A, Cibin G, Bruce DW, Hondow NS, Wilson K, Lee AF (2014) Catal Today 229:46–55

Kim LH, Kim K, Park S, Jeong YJ, Kim H, Chung DS, Kim SH, Park CE (2014) ACS Appl Mater Interface 6:6731–6738

Zhao D, Chen C, Wang Y, Ma W, Zhao J, Rajh T, Zang L (2008) Environ Sci Technol 42:308–314

Gun’ko V, Zarko V, Turov V, Leboda R, Chibowski E, Pakhlov E, Goncharuk E, Marciniak M, Voronin E, Chuiko A (1999) J Colloid Interface Sci 220:302–323

Karthikeyan S, Dionysiou DD, Lee AF, Suvitha S, Maharaja P, Wilson K, Sekaran G (2016) Catal Sci Technol 6:530–544

Zhao W, Tang Y, Wan Y, Li L, Yao S, Li X, Gu J, Li Y, Shi J (2014) J Hazard Mater 278:350–359

Haneda M, Kintaichi Y, Hamada H (2001) Appl Catal B 31:251

Zhang G, Zhang H, Yang D, Li C, Peng Z, Zhang S (2016) Catal Sci Technol 6:6417

Ma Z, Ma X, Liu H, He Y, Zhu W, Guo X, Liu Z (2017) Chem Commun 53:9071

Acknowledgements

This work was supported by the technology institute of Shanghai Huayi (Group) Company and Jilin Province Science and Technology research plan (key scientific research project). (No. 20150204020GX).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bao, Q., Qi, H., Zhang, C. et al. Highly Catalytic Activity of Ba/γ-Ti–Al2O3 Catalyst for Aldol Condensation of Methyl Acetate with Formaldehyde. Catal Lett 148, 3402–3412 (2018). https://doi.org/10.1007/s10562-018-2535-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-018-2535-9