Abstract

The acid-catalyzed conversion of lignocellulosic biomass (AC3B) process has been developed for the direct liquefaction of lignocellulosic biomass. In the original version, the main products, ethyl esters, are produced in acidic medium containing ethanol, using a one-pot conversion system. Our research strategy for obtaining a high overall performance is based on two general concepts: (a) coupling of catalytic/chemical reactions that lead to desired products and (b) decoupling of reactions that produce unwanted products, by decreasing the effectiveness of these reactions. Concept (a) is realized by using oxidizers (hydrogen peroxide and Fenton’s reagent) that promote a higher production of carboxylic acids as main intermediates, while concept (b) contributes to a significant decrease of undesired formation of polymeric products. As result of these reaction coupling and decoupling, the overall yield of liquid products has been multiplied by a factor of 2.5 (from 27 to over 70 wt%). Not only the yields of products from cellulose and hemicellulose components experience considerable increases, but also the lignin component starts undergoing a noticeable conversion. Essentially, the AC3B process, in the most recent version, consumes ethanol that is partly used to produce liquid fuels and chemicals from lignocellulosic biomass. The other amount of feed ethanol is converted—via diethyl ether and over ZSM-5-based catalysts—into aromatics-rich gasoline and liquefied petroleum gas—grade hydrocarbons.

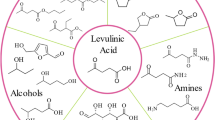

Graphical Abstract

Sequence of actions that have significantly improved the total product yield (RP): AC = acidic medium, HP = addition of hydrogen peroxide, DL-st = use of a delignification step, FR = use of a Fenton-type reagent, PIn = use of a polymerization inhibitor

Similar content being viewed by others

References

Cheng JJ (2010) In: Cheng J (ed) Biomass to renewable energy processes. CRC Press, Boca Raton

Keshwani DR (2010) In: Cheng J (ed) Biomass to renewable energy processes. CRC Press, Boca Raton, p 7

Le Van Mao R, Zhao Q, Dima G, Petraccone D (2011) Catal Lett 141:271

Girisuta B, Janssen LPBM, Heeres HJ (2006) Chem Eng Res Des 84:339

Huber GW, Iborra S, Corma A (2006) Chem Rev 106:4044

Quresshi N, Blaschek HP (2010) In: Vertes AA, Qureshi N, Blaschek HP, Yukawa H (eds) Biomass to Biofuels: Strategies for Global Industries. Wiley, U.K, p 347

Andrews DH, Singh RP (1979) In: Singh RP (ed) The Bleaching of Pulp, 3rd edn. Tappi Press, Atlanta, p 211

Legrini O, Oliveros E, Braun AM (1993) Chem Rev 93:671

Xiang Q, Lee YY (2000) Appl Biochem Biotechnol 154:84–86

Merz JH, Waters WA (1949) J Chem Soc, S15; and references therein

Mae K, Hasegawa I, Sakai N, Miura K (2000) Energy Fuels 14:1212

Czapski G, Samuni A, Meisel D (1971) J Phys Chem 75:3271

Simonetti DA, Dumesic JA (2009) Catal Rev 51:441

Hayes DJ, Fitzpatrick S, Hayes MHB, Ross RH (2006) In: Kamm B, Gruber PR, Kamm M (eds) Biorefineries—industrial processes and products, vol 1. Wiley–VCH, Weinheim, p 139

Boudart M, Djega-Mariadassou G (1994) Catal Lett 29:7

Mascal M, Nikitin EB (2010) ChemSusChem 3:1349

Yan HT, Le Van Mao R (2011) Catal Lett 141:691

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Ind Eng Chem Res 48:3713

Hasegawa I, Inoue Y, Muranaka Y, Yasukawa T, Mae K (2011) Energy Fuels 25:791

Le Van Mao R, Petraccone D, A Muntasar (Nov. 2011–Feb. 2012), Concordia University, unpublished data

Jonsson S, Persson Y, Frankki S, Bavel BV, Lundstedt S, Haglund P, Tysklind M (2007) J Harzard Mater 149:86

Wu Y, Zhou S, Qin F, Ye X, Zheng K (2010) J Harzard Mater 180:456

Andrews J, Asaadi M, Clarke B, Ouki S, Zagdaa Y (2006) J Residuals Sci Technol 3:137

Ghazi D (1994) US Patent 5,332,842

Sherwood CS (1956) US Patent 2,741,579

Fitzpatrick SW (1990) US Patent 4,897,497

Wagner GM, Hoch PE (1963) US Patent 3,101,278

Nguyen TM, Le Van Mao R (1990) Appl Catal 58:119

Le Van Mao R, Nguyen TM, McLaughlin GP (1889) Appl Catal 48:265

Le Van Mao R, Ly D, Yao J (1992) In: Albright LF, Crynes BL, Nowak S (eds) Novel production methods for ethylene, light hydrocarbons and aromatics, Chem ind 46. M Dekker, New York

Le Van Mao R, Dao LH, US Patent 4,698,452 (6 Oct. 1987)

Dahl IM, Kolboe S (1996) J Catal 161:304

Muntasar A, Le Van Mao R, Yan HT (2010) Ind Eng Chem Res 49:3611

Behrendt F, Neubauer Y, Oevermann M, Wilmes B, Zobel N (2008) Chem Eng Technol 31:667

Acknowledgments

The authors thank Mrs. Myriam Posner, Chief of Technical Staff of the Department of Chemistry & Biochemistry, the Science Technical Center (Mr. Richard Allix and Mr. Aldo Dissenga), for technical assistance, and NSERC (Natural Science and Engineering Council of Canada) for research funding.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Le Van Mao, R., Muntasar, A., Petraccone, D. et al. AC3B Technology for Direct Liquefaction of Lignocellulosic Biomass: New Concepts of Coupling and Decoupling of Catalytic/Chemical Reactions for Obtaining a Very High Overall Performance. Catal Lett 142, 667–675 (2012). https://doi.org/10.1007/s10562-012-0825-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-012-0825-1