Abstract

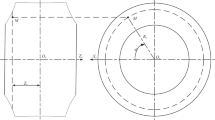

The hydrodynamics of the existing basic extrusion head of the MCH-200 screw machine were calculated using ANSYS. Pin extrusion was proposed for head modernization. A new simpler head design was developed using the directional search method. When comparing data on the distribution of material flow rates for the basic and new head designs, the efficiency of pin insertion into the extrusion head was determined.

Similar content being viewed by others

References

D.S. Dolgin, Review of the current state and development trends of heads for coextrusion of polymer materials. All-russian Sci Conf Students Undergraduates Graduate Students With Int Particip Sci Conf Abstr, Yaroslavl’, 32–35 (2019)

I.S. Gudanov, A.E. Lebedev, P.P. Yurygin, D.S. Dolgin, Stratified Flows of Rubber Mixtures in Duplex Heads [in Russian] Izdat. dom YaGTU, Yaroslavl, (2018)

V.P. Volodin, Technological Equipment in the Production of Profile Products [in Russian] COP “Professiya”, St. Petersburg (2021)

C. Hopmann, W. Michaeli, Extrusion Dies for Plastic and Rubber. Design and Engineering Computations Hanser, Publications, Cincinnati (2016)

K. Rauwendaal, M.P. Noriega, Extrusion Problems Identification and Resolving. Systematic Approach to Problem Solving [trans. from English] Ed Oa Abramushkina Professiya St Petersbg (2021)

A.V. Baranov, Dissipative flow of a viscoelastic polymer composition in a porous channel. Mekh Kompozits Mater Konstr 25(3), 316–326 (2019)

D.S. Dolgin, I.S. Gudanov, A.E. Lebedev, A.A. Vatagin, Choosing the location of the pin in the extrusion head to improve the quality of the resulting profile. Khim Neftegaz Mashinostr (2), 37–40 (2022)

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 7, pp. 41–43, July, 2023.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dolgin, D.S., Gudanov, I.S., Lavrentiev, Y.B. et al. Modernization of the tread extrusion head of the MCH-200 screw machine. Chem Petrol Eng (2024). https://doi.org/10.1007/s10556-024-01280-2

Published:

DOI: https://doi.org/10.1007/s10556-024-01280-2