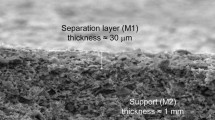

Development of microfiltration membranes used to separate emulsions of oil and water is highlighted. Oil emulsion microfiltration parameters are studied and the change in particle size of emulsion dispersed phase within membrane filtrates is established. Commercial and composite microfiltration membranes with hydrophilic and hydrophobic surfaces are used. The average pore sizes of the commercial membranes are from 0.22 to 0.45 μm, and particle sizes of the dispersed phase of the oil emulsion are in the range from 525 to 554 nm. During microfiltration of 0.1% oil emulsion, high productivity of polymer membranes is established (800–12,000 dm3/m2 · h) with an operating pressure of 0.2 MPa. After oil emulsion separation using microfiltration membranes a reduction is observed in oil product concentration, the retention capacity of commercial membranes is 88–98%, for the nylon-polystyrene dynamic membrane it is more than 99%, and for NAC-1 composite membrane with a surface layer of cellulose acetate it is 67% (relatively low). After emulsion separation a reduction is observed in dispersed phase particle size in membrane filtrates by up to a factor of ten. A reduction in the absolute value of the ζ-potential of the emulsion in membrane filtrates compared with the initial value is also revealed.

Similar content being viewed by others

References

C. Shen, Q. Zhang, and Q. Meng, “PSU-g-SBMA hollow fiber membrane for treatment of oily wastewater,” Water Science and Technology, 84, No. 12, 3576–3585 (2021).

I. Azizov, M. Dudek, and G. Øye, “Emulsions in porous media from the perspective of produced water re-injection — a review,” Journal of Petroleum Science and Engineering, 206, 109057 (2021).

D. D. Fazullin, G. V. Mavrin, and R. G. Melkonyan, “Removal of oil products and phenol from waste water by composite sorbents under dynamic conditions,” Chemistry and Technology of Fuels and Oils, 50, No. 1, 88–95 (2014).

K. I. Matiev, A. D. Agazade, M. É. Alsafarova, and A. F. Akberova, “Selection of an effective de-emulsifier for breaking down a water and oil emulsion and study for determining compatibility with a basic de-emulsifier,” Nauchnye Trudy NIPI Neftegaz GNKAR, No. 1, 75–82 (2018).

L. V. Taranova, A. G. Mozyrev, V. G. Gabdrakipova, and A. M. Glazunov, “Study of reagent-demulsifiers for industrial preparation of oil objects,” Izvest. Vyshykh Uchebnykh Zaved. Neft’ i Gaz, No. 1, 90–104 (2021).

D. D. , Fazullin and G. V. Mavrin, “Separation of water-oil emulsions using composite membranes with a cellulose acetate surface layer,” Chemical and Petroleum Engineering, 55, No. 7-8, 649–656 (2019).

D. D. Fazullin, G. V. Mavrin, and I. G. Shaikhiev, “Ultrafiltration of oil-in-water emulsions with a dynamic nylon — polystyrene membrane,” Petroleum Chemistry, 58, 145–151 (2018).

S. Jamaly, A. Giwa, and S. W. Hasan, “Recent improvements in oily wastewater treatment: Progress, challenges, and future opportunities,” Journal of Environmental Sciences, 37, 15–19 (2015).

D. D. Fazullin, G. V. Mavrin, L. I. Fazullina, et al., “Demulsification and ultrafiltration of water-oil emulsions,” Chemical and Petroleum Engineering, 57, 783–789 (2022).

P. D. Sutrisna, K. A. Kurnia, U. W. R. Siagian, S. Ismadji, and I. G. Wenten, “Membrane fouling and fouling mitigation in oil — water separation: A review,” Journal of Environmental Chemical Engineering, 10, No. 3, Article number 107532 (2022).

D. D. Fazullin and G. V. Mavrin, “Dynamic membrane with a polystyrene surface layer for ultrafiltration of spent coolant lubricant,” Chemical and Petroleum Engineering, 56, No. 3-4, 215–222 (2020).

D. D. Fazullin and G. V. Mavrin, “Effect of temperature and pH value of the liquid shared selectivity cation exchange membrane, nylon-PANI,” Research Journal of Pharmaceutical, Biological and Chemical Sciences, 6, 66–71 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 58, No. 6, pp. 23–27, June, 2022.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fazullin, D.D., Fazullina, L.I., Badertdinova, G.D. et al. Microfiltration Polymer Membranes for Separation of Oil Emulsions. Chem Petrol Eng 58, 483–490 (2022). https://doi.org/10.1007/s10556-022-01118-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-022-01118-9