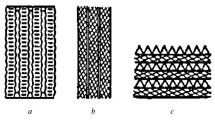

A calculation method is presented for determining the capacity of small-scale cooling towers equipped with polymeric fills under film flow conditions, for establishing the geometric dimensions and relative position of polymeric fibers comprising the mesh frame, as well as ascertaining the specific flow rate and the cooling tower capacity at which film flow conditions are provided. The presented dependences indicate that a smaller cell size in the fill pack improves the mass flow rate of the liquid to be cooled, which, however, increases the mass of the fill per unit volume of the cooling tower. In addition, it is noted that the reduced size of individual fill cells leads to a rise in the aerodynamic drag coefficient that is proportional to the specific flow rate.

Similar content being viewed by others

References

S. P. Ivanov, Improvement of Heat and Mass Transfer Processes in Water Circulation Cycles at Industrial Facilities [in Russian], Doc. Diss. Eng., 05.17.08, Ufa (2012).

A. A. Gorodilov, M. G. Berengarten, and A. S. Pushnov, “Experimental study into the mass transfer using the structured packings of direct-contact cross-flow heat exchangers,” Teor. Osn. Khim. Tekhn, 50, No. 4, 423–431 (2016).

A. G. Laptev and I. A. Ved’gaeva, Industrial Cooling Towers: Design and Calculations [in Russian], KGEU, Kazan (2004).

K. E. Bondar, N. S. Shulaev, I. G. Ibragimov, et al., Polymeric Contact Devices for Heat and Mass Transfer Processes [in Russian], UGNTU, Ufa (2016).

N. A. Merentsov, A. B. Golovanchikov, V. A. Balashov, et al., “Design calculations for a mechanical draft trickle cooling tower,” Izv. Volgograd. Gos. Tekhn. Univ., 7, No. 1 (128), 54–60 (2014).

V. A. Bogomolov, V. D. Mel’nikov, G. G. Abramova, S. A. Noskov, Cooling Tower fill (Variants), Russian Patent No. 2445567, IPC F28F25/08.; Apl. as of 05/06/2010; Publ. as of 03/202012.

K. E. Bondar, S. P. Ivanov, I. G. Ibragimov, S. V. Laponov, and D. F. Suleimanov, Small-Scale Cooling Tower, Russian Patent No. 182965, IPC F28F25/08; Appl. as of 02/26/2018; Publ. as of 09/06/2018.

K. E. Bondar’, N. S. Shulaev, and S. P. Ivanov, “Hydrodynamic tests of small-sized circulating water cooling devices,” Chem. Petrol. Eng., 56, 794–798 (2021).

E. Yanke, F. Emde, and F. Lesh, Special Functions (Formulas, Graphs, and Tables) [Russian translation], transl. from German, Sedov (editor), Nauka, Moscow (1968).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 58, No. 4, pp. 35−37, April, 2022.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bondar, K.E., Shulaev, N.S. Capacity Estimation of Circulating Water-Cooling Systems Equipped with Polymeric Fills under Film Flow Conditions. Chem Petrol Eng 58, 323–327 (2022). https://doi.org/10.1007/s10556-022-01094-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-022-01094-0