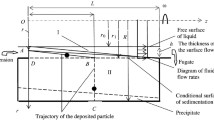

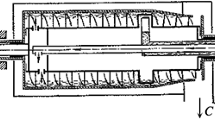

The kinetic characteristics of a two-phase fluid system in a screw centrifugal sedimenter stem from the effect on the phases of forces from the screw that initiate pressure-free (gravity) spiral flow movement inside the rotor and from the effect on the mixture components of centrifugal inertial forces that induce the sedimentation process. As the suspension flows out of the feed pipe into the conical section of the cylindroconical rotor, it is transformed under the action of the force factors into two oppositely directed flows: a wet sediment flow moving along the rotor wall and a liquid flow moving near the feed pipe counter to the sediment flow. In this work, considering the specific features of the liquid mixture treatment conditions (pressure-free steady slow movement of the fluid system components in the mobile system), in selecting a physicomathematical model, we proceeded from the scientific premises of hydrodynamics of interpermeating and interacting multiphase fluid. In this context, the characteristics of the solid sedimentation process in the working space of the centrifuge were theoretically substantiated and calculated. The characteristics disclosed by use of the obtained relationships and parameters of the fluid system separation process can be used for designing and calculating suspension clarification process in innovative centrifugal equipment prototypes.

Similar content being viewed by others

References

V. I. Sokolov, Modern Industrial Centrifuges [in Russian], Mashiostroenie, Moscow (1967).

D. E. Shkoropad, Centrifuges for Chemical Plants [in Russian], Mashiostroenie, Moscow (1975).

E. V. Semenov, “Problem of particle sedimentation in fluid centrifuges,” Teor. Osn. Khim. Tekhnol., 38, No. 4, 446–450 (2004).

I. G. Ternovskii and A. M. Kutepov, Hydrocycloning [in Russian], Nauka, Moscow (1994).

G. B. Veksler, M. G. Lagutkin, and B. G. Kalashnikov, “Calculation of indices of suspension clarification in screw sedimentation centrifuges,” Tr. MGAKhM, No. 2, 27–30 (1997).

M. G. Lagutkin, D. A. Baranov, S, Yu. Bulychev, and E. Yu. Baranova, “Calculation of separating capacity of screw sedimentation centrifuge based on determinative approach,” Khim, Neftegaz. Mashinostr., No. 5, 3–6 (2005).

R. Z. Minnigalimov and R. A. Nafikova, “Calculation of sedimentation rate of oil sludge particles in centrifugal field of decanters,” in: Collec. of Conf. Papers [in Russian], Ufa State Petroleum Engineering University, Oil and Gas Technology (2007), pp. 151–16.

E. V. Semenov and A. A. Slavyanskii, “Calculation of throughput of a continuous filtering centrifuge with screw sediment discharge,” Khim, Neftegaz. Mashinostr., No. 8, 11–15 (2017).

R. I. Nigmatulin, Dynamics of Multiphase Fluids [in Russian], Pt. II, Nauka, Moscow (1987).

E. V. Semenov and A. A. Slavyanskii, “Calculation of suspension separation process in the rotor of a continuous centrifuge,” Khim, Neftegaz. Mashinostr., No. 2, 5–9 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 57, No. 8, pp. 3−8, August, 2021.

Rights and permissions

About this article

Cite this article

Semenov, E.V., Nikitin, I.A., Chebotarev, S.N. et al. Calculation of Suspension Separation Process in Centrifugal Sedimenter Rotor with Screw Sediment Discharge. Chem Petrol Eng 57, 621–629 (2021). https://doi.org/10.1007/s10556-021-00985-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-021-00985-y