The component composition of lubrication and cooling fluid (LCF) concentrates is investigated. It is revealed that spent and fresh LCF mainly contain hydrocarbons and fatty acids, in particular stearic, palmitic, and oleic acid isomers that are used as emulsifiers and have the properties of steel corrosion inhibitors. Also within the concentrate of spent LCF presence of 2,6-di-tert-butyl-p-cresol (ionol) is revealed that is an antioxidant and is added to the oil composition to protect steel from corrosion. In this case a concentrate of spent cutting fluid of the Isanol VPS-2 grade, obtained by the method of membrane separation, is used as an inhibiting additive to protect steel (intended for pipeline manufacture) from the corrosive effects of seam water. As a result of corrosion tests it is determined that the degree of protection for steel 20 with a concentrate of spent LCF is 49 % (with a dosage of 800 mg/dm3), and with fresh cutting fluid concentrate it is 76 % (with dosage of 400 mg/dm3).

Similar content being viewed by others

References

L. V. Khudobin, Lubricant-Cooling Technological Media and Application During Cutting: Handbook [in Russian], Mashinostroenie, Moscow (2006).

I. A. Makarova, R. R. Faizov, M. V. Buzaeva, et al., “Utilization of nano-modified dispersions with lubricant-cooling liquid using natural sorbents,” Vestn. Yuzh.-Ural., Gos. Univ., Seriya: Khimiya, No. 2, 5–12 (2017).

D. D. Fazullin and G. V. Marvin, “Separation of water-oil emulsions with a composite membrane with a surface layer of cellulose acetate,” Khim. Neft. Mashin., No. 8, 24–28 (2019).

D. D. Fazullin, G. V. Mavrin, and I. G. Shaikhiev, “Evaluation and avoidance of toxicity of oil-containing waste water,” Vestn. Tekhnol. Univ., 18, No. 11, 213–216 (2015).

F. B. B. Almeida, K. P. S. Esquerre, and J. I. Soletti, “Coalescence process to treat produced water: an updated overview and environmental outlook,” Environmental Science and Pollution Research, 260, No.28 (SI), 28668–28688 (2019).

J. Hu, J. Chen, and X. Zhang, “Dynamic demulsification of oil-in-water emulsions with electrocoalescence: Diameter distribution of oil droplets,” Separation and Purification Technology, 254, 117631 (2021).

X. Feng, S. Stewart, and L. Sartori, “Understanding the effect of skim oil recycle on the water/oil separation in steam assisted gravity drainage operations,” Journal of Petroleum Science and Engineering, 192, Article number 107233 (2020).

A. Agarwal, A. Samanta, B. K. Nandi, and A. Mandal, “Synthesis, characterization and performance studies of kaolin-fly ash-based membranes for microfiltration of oily waste water,” Journal of Petroleum Science and Engineering, 194, Article number 107475 (2020).

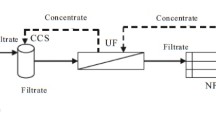

D. D. Fazullin and G. V. Mavrin, “Dynamic membrane with a polystyrene surface layer for ultrafiltration of spent coolant lubricant,” Chemical and Petroleum Engineering, 56, No. 3–4, 215–222 (2020).

V. V. Andreev, S. M. Dmitriyev, A. V. Duncev, et al., “Installation for processing oil waste for the purpose of their disposal,” Neftyanoe Khozyaystvo — Oil Industry, 5, 19–21 (2019).

D. D. Fazullin, G. V. Mavrin, and I. G. Shaikhiev, “Investigation of the properties and composition of a concentrate of spent Inkam-1 emulsion as a corrosion inhibitor,” Petroleum Chemistry, 57, No. 8, 728–733 (2017).

G. I. Drozd, Stearic Acid. Chemical Encyclopedia [in Russian], Bol’shaya Rossiiskaya Éntsiklopediya, Moscow (1995).

Work was conducted with financial support of a Russian Federation President grant for state support of young Russian scientist — science candidates (MK-1107.2019.8).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 57, No. 5, pp. 40–43, May, 2021.

Rights and permissions

About this article

Cite this article

Fazullin, D.D., Fazullina, L.I., Mavrin, G.V. et al. Use of Waste Coolant and Lubricant Concentrate for Protecting Steel from Seam Water Corrosive Action. Chem Petrol Eng 57, 430–436 (2021). https://doi.org/10.1007/s10556-021-00955-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-021-00955-4