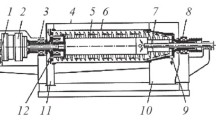

Based on the postulates of the theory of phase interaction, we studied the process of sedimentation of the solid phase of a fluid system using, as an example, treatment of a two-phase fluid system (a suspension) in the space between two close coaxial truncated cones rotating with a constant angular velocity, which imitates the space between trays of a tray separator drum.

Similar content being viewed by others

References

P. G. Romankov and S. A. Plyushkin, Fluid Separators [in Russian], Mashinostroenie, Moscow (1976).

V. A. Karpychev and E. V. Semenov, Hydromechanical Processes of Technological Treatment of Milk Products [in Russian], Legk. Pishchev. Prom., Moscow (1982).

A. M. Goldin and V. A. Karamzin, Hydrodynamic Foundations of Thin-layer Separation Processes [in Russian], Agropromizdat, Moscow (1985).

E. V. Semenov, “Calculation of suspension clarification process in rotors of separators and centrifuges,” Kolloidn. Zh., 55, No. 2, 133–138 (1993).

E. V. Semenov, V. A. Karamzin, and G. D. Novikova, Methods of Calculations of Hydrodynamic Processes in the Food Industry [in Russian], MGUPP, Moscow (2002).

A. V. Karamzin and E. V. Semenov, “Quantitative analysis of finely dispersed particles fractionation process in centrifugal separator,” Zh. Prikl. Khim., 85, No. 10, 1619–1624 (2012).

L. L. Minkov, Study of Suspension Separation Processes in Centrifugal Devices, Doctoral Dissertation [in Russian], Natsionalnyi Issledovatelskii Tomskii Gosudarstvennyi Universitet (National Research Tomsk State university), Tomsk (2012).

V. G. Zhukov and V. M. Chesnokov, “Pressure in thin-layer fluid flow in a centrifugal tray separator,” Teor. Osn. Khim. Tekhnol., 50, No. 6, 683–693 (2016).

J. G. Speight and B. Oum, Petroleum Refining Processes, Marcel Dekker inch., New York (2002).

H. K. Abdel-Aal and M. Aggour, Petroleum and Gas Field Processing, Marcel Dekker, Inc., New York (2003).

M. A. Fahim, T. A. Al-Sahhaf, and A. S. Elkilani, Fundamentals of Petroleum Refining, Elsevier Science, Amsterdam (2010).

R. I. Nigmatulin, Dynamics of Multiphase Fluids [in Russian], Pt. II, Nauka, Moscow (1987).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 57, No. 5, pp. 3−6, May, 2021.

Rights and permissions

About this article

Cite this article

Semenov, E.V., Slavyanskiy, A.A. & Mitroshina, D.P. Quantitative Analysis of Suspension Clarification Process in Inter-Tray Space of Separator Drum. Chem Petrol Eng 57, 361–369 (2021). https://doi.org/10.1007/s10556-021-00944-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-021-00944-7