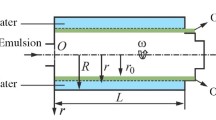

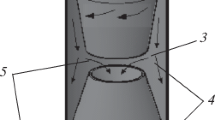

The kinetics of flow of a viscous incompressible fluid between two closely lying parabola-shaped inserts (plates) rotating with the same angular velocity around a common axis is studied. The flow, in the inter-plate gap of the separator drum, of a weakly concentrated liquid + solid type of two-phase fluid is modeled. Based on the postulates of the theory of fluid flows in “sliding” mode, the internal problem of hydrodynamics along the flow in the chosen working space of the centrifugal equipment is proposed to be solved in linear formulation. For an isolated small spherical particle moving in the flow, the critical diameter of the particle (settling in the working space of the separator), which determines the separation efficiency, is calculated by solving the external problem of hydrodynamics.

Similar content being viewed by others

References

G. I. Bremer, Fluid Separators [in Russian], Mashgiz, Moscow (1957).

P. G. Romankov and S. A. Plyushkin, Fluid Separators [in Russian], Mashinostroenie, Leningrad (1976).

V. A. Karpychev and E. V. Semenov, Hydromechanical Processes of Technological Treatment of Milk Products [in Russian], Legkaya and Pishchevaya Promyshlennosti, Moscow (1982).

A. M. Gol’din and V. A. Karamzin, Hydrodynamic Principles of Thin-layer Separation Processes [in Russian], Agropromizdat, Moscow (1985).

L. G. Loitsyanskii, Liquid and Gas Mechanics: A Textbook for Vuz (Higher Educational Institutions) [in Russian], Drofa, Moscow (2003).

A. V. Karamzin and E. V. Semenov, “Quantitative analysis of the fractionation of finely dispersed particles in a centrifugal separator,” Zh. Prikl. Khim., 85, No. 10, 1619–1624 (2012).

V. G. Zhukov and V. M. Chesnokov, “Pressure in thin-layer fluid flow of plate centrifugal separator,” Teor. Osn. Knim. Tekhnol., 50, No. 6, 683–693 (2016).

E. Madelung, Mathematical Apparatus of Physics [Russian translation from German], Nauka, Moscow (1966).

E. Kamke, Handbook of Ordinary Differential Equations [Russian translation from German], Fizmatgiz, Moscow (1961).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 55, No. 3, pp. 3–7, March, 2019.

Rights and permissions

About this article

Cite this article

Semenov, E.V., Slavyanskii, A.A. & Lebedeva, N.N. Mechanisms of Centrifugal Fluid System Separation Process in a Separator Having Double-Curved Inserts. Chem Petrol Eng 55, 175–185 (2019). https://doi.org/10.1007/s10556-019-00603-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-019-00603-y