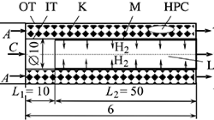

A mathematical model for membrane extraction of high-purity hydrogen from methane steam-conversion products that takes into account hydrogen outflow through a palladium membrane (V-1 alloy) and chemical reactions among components of the starting gas mixture in the presence of a carbon monoxide conversion catalyst is presented. A practical example shows that the presented model describes adequately and rather accurately the main parameters of the model membrane reformer with the carbonmonoxide catalyst and allows the optimal technological regimes to be selected.

Similar content being viewed by others

References

F. Gallucci, E. Fernandez, P. Corengia, and M. Annaland, “Recent advances on membranes and membrane reactors for hydrogen production (Review),” Chem. Eng. Sci., 92, 40–66 (2013).

G. F. Tereshchenko, N. V. Orekhova, and M. M. Ermilova, “Metal-containing membrane reactors,” Krit. Tekhnol. Membr., No. 1, 4–20 (2007).

Y. Shirasaki, T. Tsuneki, Y. Ota, et al., “Development of membrane reformer system for highly efficient hydrogen production from natural gas,” Int. J. Hydrogen Energy, 34, No. 10, 4482–4487 (2009).

K. R. Hwang, C.-B. Lee, S.-K. Ryi, and J.-S. Park, “Hydrogen production and carbon dioxide enrichment using a catalytic membrane reactor with Ni metal catalyst and Pd-based membrane,” Int. J. Hydrogen Energy, 36, 6626–6634 (2012).

G. Chiappetta, G. Clarizia, and E. Drioli, “Theoretical analysis of the effect of catalyst mass distribution and operation parameters on the performance of a Pd-based membrane reactor for water — gas shift reaction,” Chem. Eng. J., 136, 373–382 (2008).

A. B. Shigarov and V. A. Kirillov, “Modeling of membrane reactor for steam methane reforming: From granular to structured catalysts,” Teor. Osn. Khim. Tekhnol., 46, No. 2, 131–142 (2012).

F. Gallucci, L. Paturzo, and A. Basile, “A simulation study of the steam reforming of methane in a dense tubular membrane reactor,” Int. J. Hydrogen Energy, 29, No. 6, 611–617 (2004).

F. A. N. Fernandes and A. B. Soares, “Modeling of methane reforming in a palladium membrane reactor,” Lat. Am. Appl. Res., 36, No. 3, 155–161 (2006).

L. L. Murav’ev, A. B. Vandyshev, and V. M. Makarov, “Modeling of membrane extraction of hydrogen from the products of steam conversion of hydrocarbons,” Teor. Osn. Khim. Tekhnol., 33, No. 3, 286–291 (1999).

A. B. Vandyshev, “Analyzing the parameters of membrane catalytic systems for extraction of highly pure hydrogen from hydrocarbon feedstock with the application of mathematical modeling,” Diagn., Resour. Mech. Mater. Struct. (DREAM open-access journal), No. 4, 6–45 (2016).

V. A. Kirillov, V. D. Meshcheryakov, O. F. Brizitskii, and V. Ya. Terent’ev, “Analysis of a power system based on low-temperature fuel cells and a fuel processor with a membrane hydrogen separator,” Teor. Osn. Khim. Tekhnol., 44, No. 3, 243–251 (2010).

V. A. Kirillov and V. D. Meshcheryakov, “Modeling of membrane reactor for steam CO conversion for pure-hydrogen production from synthesis gas,” Khim. Prom-st. Segodnya, No. 3, 33–36 (2009).

A. B. Vandyshev and V. A. Kulikov, “Hydrogen permeability of palladium membranes made of alloy V-1 in laboratory investigations and membrane devices,” Khim. Neftegazov. Mashinostr., No. 6, 18–21 (2015).

L. L. Murav’ev, A. B. Vandyshev, and V. M. Makarov, “Modeling of membrane extraction of hydrogen from multicomponent gas mixtures,” Teor. Osn. Khim. Tekhnol., 33, No. 2, 190–192 (1999).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 54, No. 5, pp. 17−21, May, 2018.

Rights and permissions

About this article

Cite this article

Vandyshev, A.B., Kulikov, V.A. Modeling a Membrane Reformer with a Carbon-Monoxide Conversion Catalyst for Extracting High-Purity Hydrogen from Methane Steam-Conversion Products. Chem Petrol Eng 54, 313–321 (2018). https://doi.org/10.1007/s10556-018-0481-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-018-0481-4