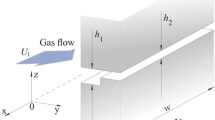

To increase the efficiency of mass-21transfer apparatuses, a stream-bubble contact device with intensive countercurrent contact between the gas (vapor) and liquid in each element is proposed. This way of effecting phase contact helps increase mass-transfer coefficients and, consequently, increase efficiency of masstransfer processes significantly. In the proposed contact device, hydraulic resistance is low. The profile and parameters of liquid drops atomizing may differ markedly, depending on the design and process parameters of the contact device and of the apparatus as a whole.

Similar content being viewed by others

References

A. I. Skoblo, Yu. K. Molokanov, A. I. Vladimirov, and V. A. Shchelkunov, Processes and Apparatuses of Petroleum and Gas Refining and Petroleum Chemistry, Gubkin Russian State University of Oil and Gas, Moscow (2012).

A. S. Pushnov, A. S. Sokolov, and M. M. Butrin, “Methods of intensification of heat- and mass-transfer processes in column apparatuses having contact devices,” Izv. Mosk. Gos. Tekhn. Univ. MAMI, 4, No. 1 (15), 237–242 (2013).

A. V. Dmitriev, I. R. Kalimullin, and A. N. Nikolaev, “Variation of liquid level in stages of mass-transfer unit with direct-flow/vortical contact devices,” Chem. Petrol. Eng., 46, No. 7–8, 446–450 (2010).

N. Kolev, B. Kralev, and D. Kolev, “Gas side controlled mass transfer in a new packing with stamped horizontal lamellae operating at extremely low liquid loads,” Chem. Eng. Proces.: Process Intensif., 63, 44–49 (2013).

Z. J. Wei, Z. L You, and S. Q. Gui, “Gas pressure drop and mass transfer characteristics in a cross-flow rotating packed bed with porous plate packing,” Industr. Eng. Chem. Res., No. 49 (8), 3732–3740 (2010).

I. N. Madyshev, G. Kh. Gumerova, A. N. Nikolaev, et al., Application for Useful Model No. 2014149169 (079099), “Heat- and mass-transfer plate with stream-bubble contact devices,” subm. 12.05.2014.

I. N. Madyshev, A. N. Nikolaev, O. S. Dmitrieva, and A. V. Dmitriev, “Optimization of design of stream-bubble contact devices of mass-transfer apparatuses of industrial thermal power stations,” Prom. Energet., No. 11, 17–20 (2014).

A. A. Ovchinnikov, Dynamics of Two-Phase Whirling Turbulent Flows in Vortex Separators, Novoe Znanie, Kazan (2005).

A. V. Dmitriev, O. S. Dmitrieva, and A. N. Nikolaev, “Determination of characteristic parameters of vortex chambers with a disk sprayer for cooling return water,” Prom. Energet., No. 8, 32–36 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 5, pp. 3–6, May, 2016.

Rights and permissions

About this article

Cite this article

Madyshev, I.N., Dmitrieva, O.S., Dmitriev, A.V. et al. Study of Fluid Dynamics of Mass-Transfer Apparatuses Having Stream-Bubble Contact Devices. Chem Petrol Eng 52, 299–304 (2016). https://doi.org/10.1007/s10556-016-0189-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-016-0189-2