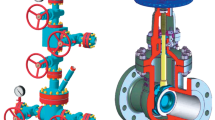

It is established by laboratory bench-test experiments that with the existing gate valve construction with a parallel-sided gate under medium pressure pulsations there is wear of surfaces in contact due to fretting corrosion. The materials used, assembly structural parameters, and vibration have the greatest effect on wear intensity. Recommendations are made for improving the design of the locking assembly for direct-flow high-pressure gate valves.

Similar content being viewed by others

References

S. G. Babaev and V. I. Kerimov, “Study of reasons for corrosion and mechanical wear of Christmas tree fitting gate valve components, ” Azerbaijan State Oil Academy, Research Institute of Geotechnological Problems of Oil, Gas, and Chemistry: Sci. Works, Izd. Çaşıoğlu, Baku (2000), Vol. II, pp. 137–141.

G. N. Garkunov, Tribology, Mashinostroenie, Moscow (1985).

S. G. Babaev and V. I. Kerimov, Patent 1 2004.0143 Azerbaijan, “Bench unit for testing high-pressure gate valves,” State reg. 09.07.2004.

S. G. Babaev and V. I. Kerimov, “Results of bench tests for a gate valve assembly under pressure pulsation conditions,” Azerbaijan State Oil Academy, Research Institute of Geotechnological Problems of Oil, Gas, and Chemistry: Sci. Works, Izd. BSU, Baku (2003), Vol. IV, pp. 237–245.

S. G. Babaev and V. I. Kerimov, “Recommendations for improving the operating capacity of a Christmas tree fitting gate valve assembly,” Azerbaijan State Oil Academy, Research Institute of Geotechnological Problems of Oil, Gas, and Chemistry: Sci. Works, Izd. Nurlan, Baku (2010), Vol. X, pp. 258–267.

S. G. Babaev, V. A. Abassov, V. V. Gafarov, and V. I. Kerimov, “Basis and choice of a method for preparing and restoring sealing elements of Christmas tree fitting gate valve locking elements,” Mekh. Mashinostr., No. 1, 14–24 (2004).

S. G. Babaev, L. S. Kerimov, and V. I. Kerimov, Patent 1 20080079 Azerbaijan, State reg. 04.30.2008.

S. G. Babaev and V. I. Kerimov, “Results of improving the reliability of direct flow high-pressure gate valves used in Christams tree and pipeline fittings,” Mashinostroitel, No. 5, 20–24 (2012).

S. G. Babaev, Oil Industry Equipment Reliability, Nedra, Moscow (1987).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 8, pp. 15–17, August, 2015.

Rights and permissions

About this article

Cite this article

Babaev, S.G., Kerimov, V.I. Increase in the Working Capacity of Christmas-Tree Gate Valves Based on Studying the Wear Mechanism of a Gate and Seat Pair. Chem Petrol Eng 51, 526–529 (2015). https://doi.org/10.1007/s10556-015-0080-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-015-0080-6